Application Case | Laser displacement sensor accurately measures liquid height in 3D printing equipment

- Share

- Issue Time

- Jun 4,2024

Summary

By converting from the laser into electrical signals. determine various characteristics,distance, displacement, or position.

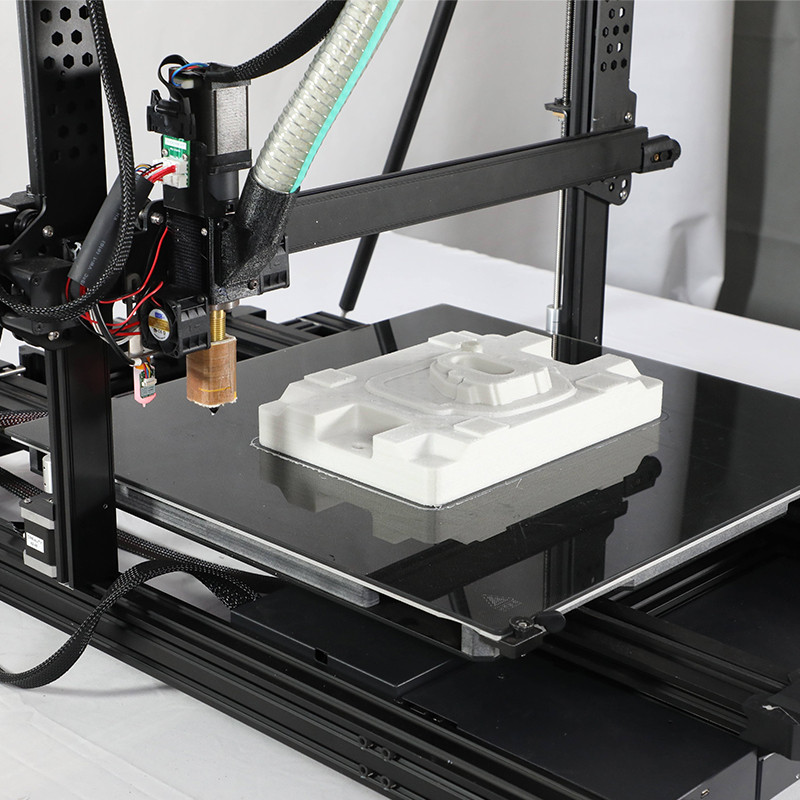

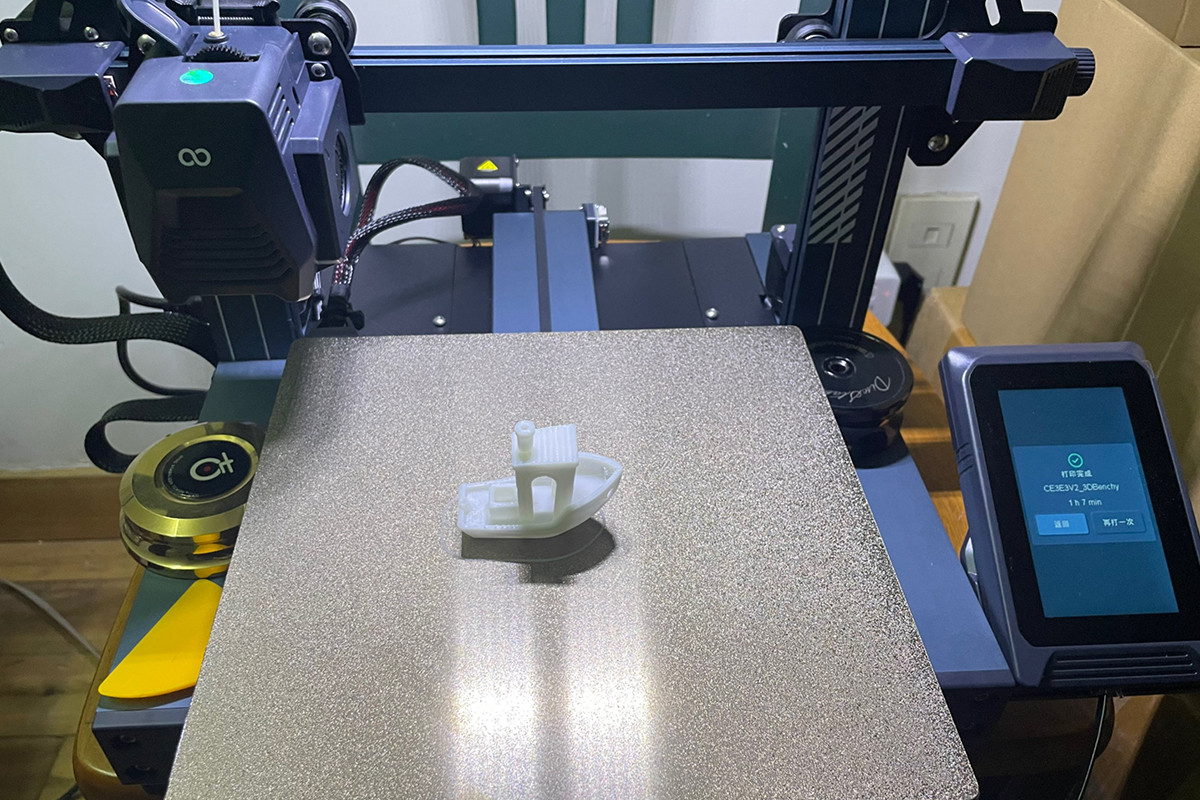

Three-dimensional (3D) printing is an emerging technology in the manufacturing industry, known as "a manufacturing technology with industrial revolutionary significance". With the advancement of science and technology, three-dimensional (3D) printing is gradually developing and penetrating into life and production, changing the production processes in many fields such as electronic manufacturing, optical devices, robot manufacturing, bioengineering and sensor technology.

In this increasingly sophisticated process, precision control systems inevitably play a big role.

This issue shares the application of DADISICK laser displacement sensors in 3D printers

Project Requirements

1. Detect the height of liquid resin (analog output);

2. Repeatability accuracy requirement is 0.1mm, detect the height difference of liquid level, and automatically compensate for the difference.

Recommended Model

1. Liquid resin has strong reflectivity. Customers used laser displacement products from other brands and were unable to achieve stable detection results.

2. The fluidity of the liquid poses a certain challenge to the stability of the detection data.

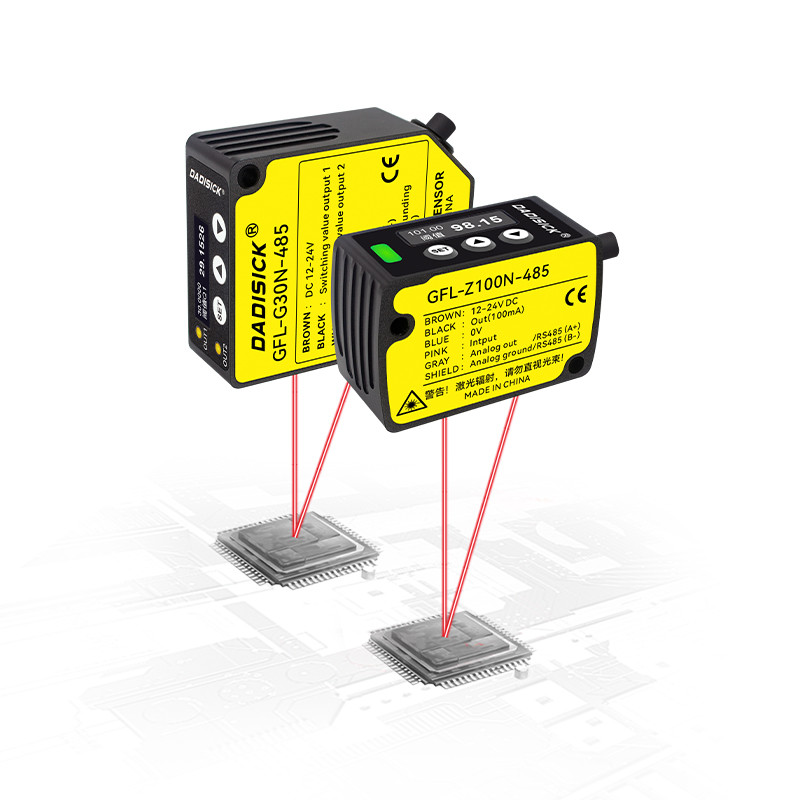

Recommended Model

Laser Distance Displacement Sensor

1. Triangulation optical detection principle design, can accurately detect;

2. Minimum resolution 2μm, humanized panel design;

3. 3-speed response time mode adjustable, the fastest can reach 2.5ms;

4. The spot size is about 0.15x0.15mm, which can stably detect tiny objects;

5. Unique Chinese and English display screen and software design, easy to operate.