Application case | Measuring Light Curtains in Woodworking Machinery: Log Diameter, Length Detection, Cutting Sorting, and Deformation Detection

- Share

- publisher

- Zoe

- Issue Time

- Jul 24,2024

Summary

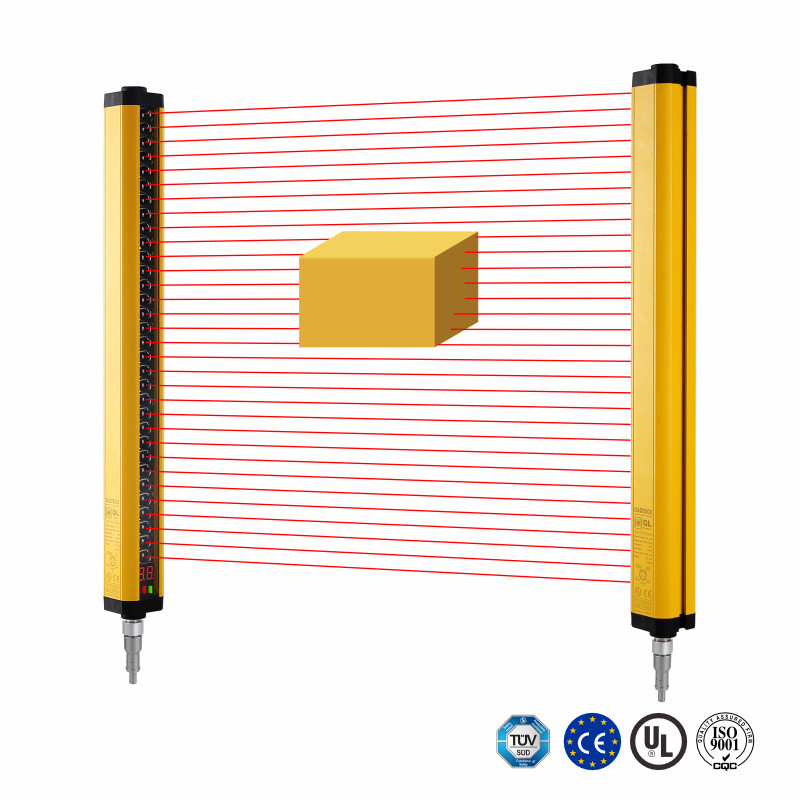

DADISICK's measuring light curtains are widely used in various fields such as logistics separation, shape dimension detection, hole detection, and spraying. The QL series measuring light curtains adopt the standard MODBUS protocol (supporting RS485 or RS232 communication functions) to communicate with the host computer, featuring high precision and high performance. They can also be customized according to customer needs.

Measuring Light Curtains in Woodworking Machinery: Log Diameter, Length Detection, Cutting Sorting, and Deformation Detection

Log Diameter Measurement

In the woodworking machinery industry, measuring the diameter of logs is a critical step before processing. Measuring light curtains use infrared sensor technology to accurately measure the diameter of logs in a non-contact manner. The principle is that as the product passes through the light curtain detection area, it blocks a certain number of light beams. The light curtain calculates the change in the number of blocked beams to measure the diameter. This method is not only highly accurate (up to 1mm) but also responds quickly, avoiding damage or deformation to the wood that can occur with traditional contact measurements.

Log Length Detection

Measuring light curtains also excel at detecting log lengths. As logs pass through the light curtain detection area, the light curtain can monitor and calculate the length of the logs in real-time. This online detection method not only improves production efficiency but also ensures the accuracy of the measurements. Operators only need to set the measurement parameters, and the machine will automatically complete the length measurement, significantly reducing labor costs and errors.

Cutting and Sorting

In automated woodworking production lines, measuring light curtains are often combined with cutting equipment to achieve precise cutting and automatic sorting of logs. Using the size information obtained from the measuring light curtains, the cutting equipment can automatically adjust cutting parameters to ensure that the cut boards or wood segments are precise and uniform in size. Additionally, the sorting system can automatically sort logs or wood segments of different sizes into designated positions based on data provided by the measuring light curtains, facilitating subsequent processing.

Deformation Detection

Wood may bend and deform during processing, which not only affects product quality but can also cause difficulties in subsequent processing. Measuring light curtains can monitor wood deformation in real-time. Since bending deformation causes changes in the wood's length, the measuring light curtain can detect these slight changes in length to identify whether the wood has deformed. If deformed wood is detected, the system can automatically stop or remove it from the production line, ensuring product quality and production safety.

Log Diameter Measurement Solution

Application Scenario Analysis

Process Step: Sorting line, at the front end of the conveyor belt

Application: Before entering the debarking equipment, the infrared measuring light curtain quickly and accurately measures the diameter of the logs. Based on the measurement results, the fixtures and debarking tools are automatically adjusted to ensure stable production and equipment safety.

From the video on the left, you can see that our customer is using DADISICK's QL series measuring light curtains.

Recommended Measuring Light Curtains

◾ 1.25 mm High-Precision Measurement and Detection.

◾ Designed with dimensions of 36 mm x 36 mm, the safety sensor can connect to cables (M12) through an aviation connector.

◾ Comprehensive self-check function ensures that no erroneous signals are sent to controlled electrical devices when the safety sensor malfunctions.

◾ Strong anti-interference capability: The system has excellent resistance to electromagnetic signals, strobe lights, welding arcs, and surrounding light sources.

◾ Adopts surface-mount technology, providing superior shock resistance.

◾ Compliant with IEC61496-1/2 safety standards of the International Electrotechnical Commission, certified by TUV and UL.

◾ Short response time (≤15 ms), high safety and reliability.

◾ Easy installation and debugging, simple wiring, and compact appearance.

QL Series Measuring Light Curtains Models

Description:

- For example: QL08-40-280: QL series, 8 beams, 40 mm beam spacing, 280 mm protective height;

- Switching output: NPN or PNP;

- Communication interface: RS485 or RS232;

- Analog signal output: 1 - 10 V or 4 - 20 mA;

- Baud rate: 4800 bit/s, 9600 bit/s, 19200 bit/s, 38400 bit/s, baud rate can be modified arbitrarily;

- Signal transmission mode: active transmission or passive transmission;

- Data upload mode: full status upload or upload only the high, low position, and total number of interrupted beams;

- Detection distance: 0.3 m to 3 m or 0.3 m to 6 m, the maximum detection distance for beam spacing of 20/40/80 mm can reach 30 m;

- Standard configuration supports up to 500 beams, additional beams can be customized.

2.5 mm Beam Spacing |

|||||||

|

QL32-2.5-77.5

|

QL40-2.5-97.5

|

QL48-2.5-117.5

|

QL56-2.5-137.5

|

QL64-2.5-157.5 | QL72-2.5-177.5 | QL80-2.5-197.5 | QL88-2.5-217.5 |

|

QL96-2.5-237.5

|

QL104-2.5-257.5

|

QL112-2.5-277.5

|

QL120-2.5-297.5

|

QL128-2.5-317.5 | QL136-2.5-337.5 | QL144-2.5-357.5 | QL152-2.5-377.5 |

|

QL160-2.5-397.5

|

QL168-2.5-417.5

|

QL176-2.5-437.5

|

QL184-2.5-457.5

|

QL192-2.5-477.5 | QL200-2.5-497.5 | QL208-2.5-517.5 | QL216-2.5-537.5 |

QL224-2.5-557.5 | QL232-2.5-577.5 | QL240-2.5-597.5 | QL248-2.5-617.5 | QL256-2.5-637.5 | QL264-2.5-657.5 | QL272-2.5-677.5 | QL280-2.5-697.5 |

QL288-2.5-717.5 | QL296-2.5-737.5 | QL304-2.5-757.5 | QL312-2.5-777.5 | QL320-2.5-797.5 | QL328-2.5-817.5 | QL336-2.5-837.5 | QL344-2.5-857.5 |

QL352-2.5-877.5 | QL360-2.5-897.5 | QL368-2.5-917.5 | QL376-2.5-937.5 | QL384-2.5-957.5 | QL392-2.5-977.5 | QL400-2.5-997.5 | QL408-2.5-1017.5 |

QL416-2.5-1037.5 | QL424-2.5-1057.5 | QL432-2.5-1077.5 | QL440-2.5-1097.5 | QL448-2.5-1117.5 | QL456-2.5-1137.5 | QL464-2.5-1157.5 | QL472-2.5-1177.5 |

QL480-2.5-1197.5 | |||||||

5 mm Beam Spacing | |||||||

QL16-5-75 | QL24-5-115 | QL32-5-155 | QL40-5-195 | QL48-5-235 | QL56-5-275 | QL64-5-315 | QL72-5-355 |

QL80-5-395 | QL88-5-435 | QL96-5-475 | QL104-5-515 | QL112-5-555 | QL120-5-595 | QL128-5-635 | QL136-5-675 |

QL144-5-715 | QL152-5-755 | QL160-5-795 | QL168-5-835 | QL176-5-875 | QL184-5-915 | QL192-5-955 | QL200-5-995 |

QL208-5-1035 | QL216-5-1075 | QL224-5-1115 | QL232-5-1155 | QL240-5-1195 | QL248-5-1235 | QL256-5-1275 | QL264-5-1315 |

QL272-5-1355 | QL280-5-1395 | QL288-5-1435 | QL296-5-1475 | QL304-5-1515 | QL312-5-1555 | QL320-5-1595 | QL328-5-1635 |

QL336-5-1675 | QL344-5-1715 | QL352-5-1755 | QL360-5-1795 | QL368-5-1835 | QL376-5-1875 | QL384-5-1915 | QL392-5-1955 |

QL400-5-1995 | QL408-5-2035 | QL416-5-2075 | QL424-5-2115 | QL432-5-2155 | QL440-5-2195 | QL448-5-2235 | QL456-5-2275 |

QL464-5-2315 | QL472-5-2355 | QL480-5-2395 | QL488-5-2435 | QL496-5-2475 | |||

10 mm Beam Spacing | |||||||

QL08-10-70 | QL10-10-90 | QL12-10-110 | QL14-10-130 | QL16-10-150 | QL18-10-170 | QL20-10-190 | QL22-10-210 |

QL24-10-230 | QL26-10-250 | QL28-10-270 | QL30-10-290 | QL32-10-310 | QL34-10-330 | ||

20 mm Beam Spacing | |||||||

QL04-20-60 | QL06-20-100 | QL08-20-140 | QL10-20-180 | QL12-20-220 | QL14-20-260 | QL16-20-300 | QL18-20-340 |

QL20-20-380 | QL22-20-420 | QL24-20-460 | QL26-20-500 | QL28-20-540 | QL30-20-580 | QL32-20-620 | |

40 mm Beam Spacing | |||||||

QL04-40-120 | QL06-40-200 | QL08-40-280 | QL10-40-360 | QL12-40-440 | QL14-40-520 | QL16-40-600 | QL18-40-680 |

QL20-40-760 | QL22-40-840 | QL24-40-920 | QL26-40-1000 | QL28-40-1080 | QL30-40-1160 | QL32-40-1240 | QL34-40-1320 |

QL36-40-1400 | QL38-40-1480 | QL40-40-1560 | QL42-40-1640 | QL44-40-1720 | QL46-40-1800 | QL48-40-1880 | QL50-40-1960 |

QL52-40-2040 | QL54-40-2120 | QL56-40-2200 | QL58-40-2280 | QL60-40-2360 | QL62-40-2440 | QL64-40-2520 | QL66-40-2600 |

QL68-40-2680 | QL70-40-2760 | QL72-40-2840 | |||||

80 mm Beam Spacing | |||||||

QL04-80-240 | QL06-80-400 | QL08-80-560 | QL10-80-720 | QL12-80-880 | QL14-80-1040 | QL16-80-1200 | QL18-80-1360 |

QL20-80-1520 | QL22-80-1680 | QL24-80-1840 | QL26-80-2000 | QL28-80-2160 | QL30-80-2320 | QL32-80-2480 | QL34-80-2640 |

QL36-80-2800 | QL38-80-2960 | QL40-80-3120 | |||||

Downloads

Related Safety Products & Accessories

Beam spacing: 5mm

Number of optical axes: 128

Protection height: 675mm

Reliable installation for light curtain, quick and easy adjustment, strong design, suitable for harsh industrial environment

The rotating bracket allows the light curtain to rotate around its longitudinal axis and adjust its position

It can be directly put into the aluminum groove, in the process of installation, it can automatically locate and lock.

The safety light curtain are fixed on support,and then debug according to the specific situation.