Application of Economical Safety Light Curtain in the Protection of Dangerous Points in Test Stations

- Share

- publisher

- Vicky

- Issue Time

- Sep 19,2024

Summary

Economical safety light curtains have become a key tool in the protection of dangerous points in test stations due to their high cost-effectiveness, ease of use and reliability. They not only ensure the safety of operators, but also improve production efficiency and reduce operating costs. With technological advances, economical safety light curtains will be widely used in more industrial fields, helping companies achieve a more efficient and safe production environment.

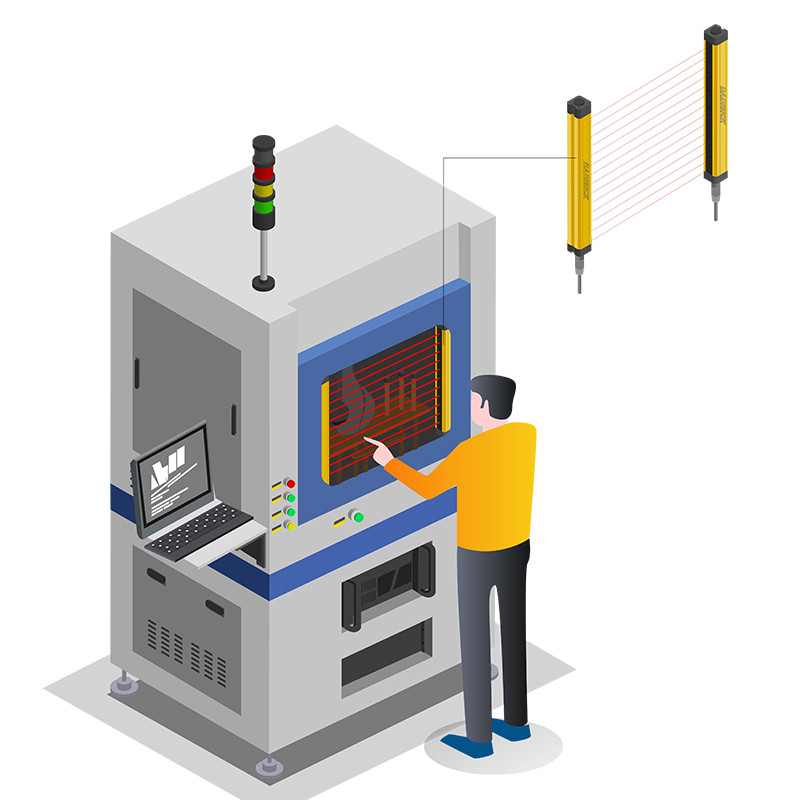

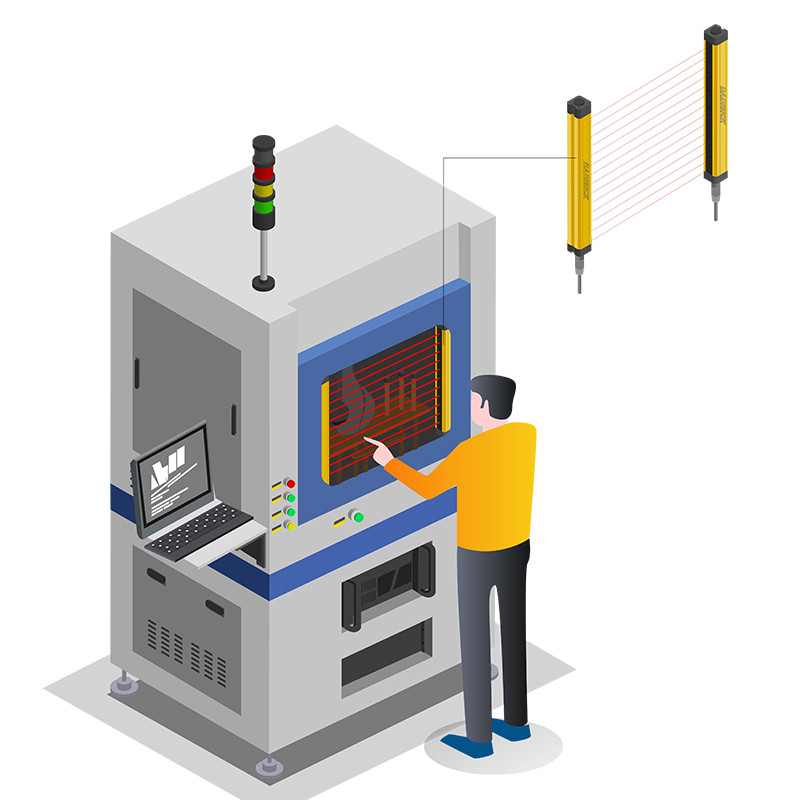

In modern industrial production, test stations are an important part of ensuring product quality and functional stability. Usually, test stations involve complex mechanical equipment and operating procedures, so there are many potential safety risks, such as equipment misoperation, component movement, and high-voltage systems. These risks pose a threat to the safety of operators and equipment at the station. Therefore, how to ensure operational safety while ensuring production efficiency has become an urgent problem that companies need to solve.

Economical safety light curtains have been widely used in hazardous point protection applications at test stations due to their high cost-effectiveness, ease of use, and high reliability. The following will introduce the application and advantages of economical safety light curtains in hazardous point protection at test stations.

Functional Features of Economical Safety Light Curtains

The economical safety light curtain is a non-contact safety protection device that uses infrared detection technology to monitor the protection area by emitting and receiving light beams. When an object or person enters the protection area, the light curtain will detect the signal interruption and automatically trigger the preset safety measures, such as emergency stop equipment or alarm. Its main functional features include:

High cost performance

Compared with high-end safety light curtains, economical light curtains have obvious advantages in price, but they also have reliable safety protection capabilities in basic functions.

Easy to install and maintain

Economical safety light curtains have simple structures, easy installation, suitable for various workstation environments, and no complicated debugging is required during maintenance, which reduces the company's operation and m

aintenance costs.

High detection accuracy

Although they are economical equipment, modern economical safety light curtains can still provide high detection accuracy to ensure rapid response to people and objects.

Protection Requirements for Hazardous Points at Test Stations

There may be several common danger points at the test station:

Mechanical moving parts

During the test, some mechanical arms, conveyor belts or fixtures will move frequently, which may cause harm to personnel.

High-voltage equipment

Some tests may involve high-voltage circuits or other dangerous energy sources. Misoperation by personnel may cause electric shock or equipment damage.

Risk of misoperation

When the operator is testing the product, if he or she accidentally operates improperly, it may trigger dangerous actions of the equipment, causing injury or equipment damage.

For this reason, the economical safety light curtain can provide reliable protection, monitor the dangerous area of the test station, and prevent personnel from entering or misoperating.

Application Scenarios of Economical Safety Light Curtains in Test Stations

In actual test stations, economical safety light curtains can be used in the following scenarios:

Quipment perimeter protection

Install safety light curtains around the mechanical equipment at the test station. When the operator approaches the dangerous area of the equipment, the light curtain detects signal interruption and immediately issues an alarm or stops the equipment.

Operation table protection

Set up an economical safety light curtain in front of the operation table to ensure that when the operator's hands reach into the dangerous area, the light curtain can detect and trigger the equipment to stop in real time to avoid hand injuries.

Access control system protection

The test station may have a safety door or a protective door. By setting a safety light curtain at the door, the equipment is prevented from continuing to run when the door is open, protecting the safety of personnel.

Advantages of Economical Safety Light Curtains

In the protection of dangerous points at the test station, the economical safety light curtain has the following advantages:

Reducing safety risks

The economical safety light curtain can monitor the dangerous area in real time and trigger an emergency stop or alarm when a person enters by mistake, reducing the occurrence of safety accidents.

Improving production efficiency

Compared with traditional safety protection measures (such as mechanical guardrails or safety doors), the non-contact design of the economical safety light curtain can be more flexibly applied to various areas of the station, avoiding the impact of frequent opening and closing of guardrails on production efficiency.

Reducing costs

The economical safety light curtain is affordable, and enterprises can achieve efficient safety protection at a lower cost, which is particularly suitable for small enterprises or projects with limited budgets.

Installation and Commissioning of Economical Safety Light Curtain

When applying economical safety light curtains at test stations, correct installation and commissioning are key steps to ensure their effectiveness. During installation, it is necessary to determine the protection range and height of the light curtain according to the hazardous area of the station, and ensure that the transmitter and receiver are aligned to ensure stable transmission of infrared signals. At the same time, multiple tests should be carried out during the commissioning process to verify the sensitivity and response speed of the safety light curtain to ensure that it can react quickly when people or objects enter the protection area.

DADISICK's Hot Selling Safety Light Curtains

Beam spacing:20mm

Number of optical axes: 40

Protection height: 780mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing: 10mm

Number of optical axes: 102

Protection height: 1010mm

Safety curtain outputs (OSSD): 2 PNP

Beam spacing:40mm

Number of optical axes: 20

Protection height: 760mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing:40mm

Number of optical axes: 54

Protection height: 2120mm

Safety Curtain outputs (OSSD):2 PNP