Application of Fork Sensors in Labeling Machines: Label Detection

- Share

- publisher

- Zoe

- Issue Time

- Oct 6,2024

Summary

The CSDB series ultrasonic fork sensor uses a slot-type detection method, enabling precise positioning of labels in high-speed motion. It is easy to install, requires no alignment, offers high sensitivity, and saves space, making it ideal for labeling machines handling various types of labels.

Label Detection

The CSDB ultrasonic fork sensor is used to detect the printing method, transparency, and surface roughness of labels and their carrier materials, as well as to identify whether the material is a single or double layer. For example, it can detect transparent labels on transparent carrier materials and different printed patterns on the labels.

The CSDB ultrasonic fork sensor can detect labels with a minimum spacing of 2mm, offering high positioning accuracy, fast response time, and a compact size, making it widely applicable. The CSDB sensor operates based on the ultrasonic principle, detecting signal attenuation caused by variations in material thickness.

• Slot-type design, compact size, space-saving, capable of detecting transparent, non-transparent, semi-transparent label and printed labels.

• Response time: 250μS.

• PNP + NPN switching output.

• Accurate monitoring even at high conveyor speeds, thanks to the short response time.

• The sensor housing includes an LED indicator and a switch button on the top, making setup simple and fast with the teach-in function.

• Standard operating voltage: DC 10-30V.

• Equipped with temperature compensation.

• CSDB with IO-Link: Easy Configuration + Convenient Recipe Management

Application of Ultrasonic Fork Sensors in Labeling Machines in the Packaging Industry

With the continuous development of automation technology, the demand for label detection in the packaging industry is increasing. During packaging, labels of various shapes, sizes, and materials can be applied to products and packaging through labeling machines. The quality of label application is crucial to the entire process. Even on high-speed conveyor belts, labels must be precisely positioned on the product or packaging. To ensure high-quality label application, reliable label detection is essential. Fork sensors are specifically designed for this task. As an efficient and precise label detection device, ultrasonic fork sensors, with their unique slot-type design, high sensitivity, and operational safety, have been widely used in the packaging industry.

Benefits of Ultrasonic Fork Sensors in Labeling Machines

✅ Precise Label Positioning: Ultrasonic fork sensors can accurately detect the contrast between labels and the background material, ensuring correct and stable label placement during the labeling process.

✅ High Adaptability: These sensors are unaffected by label color, material, or the gap between labels, allowing for stable detection of transparent, semi-transparent, and opaque labels.

✅ Fast Response: During high-speed labeling, labels and their gaps quickly pass through the sensor. The ultrasonic fork sensor's fast response ensures precise label detection and counting.

✅ Easy Installation: The sensor is simple to install, requires no precise alignment, has high sensitivity, and saves space, making it ideal for use in various labeling machine operations.

Working Principle of Fork Sensors

The working principle of ultrasonic fork sensors is based on the transmission and reception of ultrasonic signals. One side of the sensor contains an ultrasonic transmitter, and the other side has a receiver. The transmitter continuously emits ultrasonic signals, and as the label passes through the detection area, the differences in thickness, density, and transparency of the materials result in varying signal attenuation. The sensor detects these variations to accurately identify the position and state of the label. This ultrasonic detection principle effectively identifies transparent, semi-transparent, and opaque labels, ensuring precise label positioning even on high-speed conveyors.

Application of Ultrasonic Fork Sensors in Labeling Machines

Requirement:

The packaging industry often faces challenges in detecting transparent or semi-transparent labels on a combination of label and carrier materials. The need is for a reliable solution that can accurately detect such labels, ensuring correct placement on high-speed labeling machines without being affected by the label's transparency or the material's texture.

Solution:

To address this requirement, an ultrasonic fork sensor is an ideal choice. Its detection mechanism, based on ultrasonic waves, allows it to differentiate between the label and the carrier material regardless of the label's transparency. The ultrasonic sensor operates by emitting and receiving sound waves that can penetrate both transparent and semi-transparent materials. As the label and carrier pass through the sensor’s slot, the sensor measures variations in material thickness and density, detecting the presence of the label without being influenced by optical properties.

The ultrasonic fork sensor can accurately detect labels with minimal spacing between them, making it suitable for high-speed operations. With a fast response time, compact design, and ease of installation, this sensor provides reliable and efficient label detection, ensuring smooth and accurate labeling processes on various packaging lines. Additionally, the sensor offers both NPN and PNP output options, allowing for flexible integration into existing control systems.

NPN/PNP Output Options

Ultrasonic fork sensors provide both NPN and PNP switching output options, allowing for seamless integration into different industrial control systems.

NPN Output: This “sinking current” mode connects the output signal to ground when a label is detected, making it compatible with control systems that require low-level signal input.

PNP Output: This “sourcing current” mode connects the output signal to a positive voltage when a label is detected, suitable for control systems that require high-level signal input.

These output modes offer flexible integration options depending on the system requirements, ensuring compatibility with PLCs, relays, and other control devices.

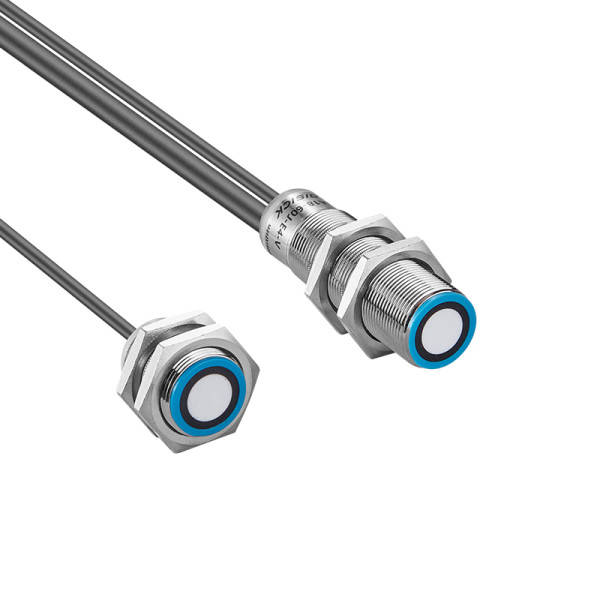

Related Measurement Sensors

Groove depth: 68 mm

Slot width: 5 mm

Material: metal, aluminum

Connection type: 4-pin M8 connector

Response time: up to 1.5ms

Repetitive accuracy: up to 10µm

Output method: NPN/PNP+analog+RS485

Resolution: 1mm

Laser type: red semiconductor laser Class II laser 655+10nm<1m

Reaction time: 50-200ms

Emitter - receiver spacing: 20-40 mm, 20-60 mm, 20-100 mm

Material: nickel plated copper, plastic fittings

Connection type: 2 m, PVP cable, 0.14 mm²