Application of Laser Distance Sensors in Carton Warehouse Level Monitoring

- Share

- publisher

- Zoe

- Issue Time

- Sep 6,2024

Summary

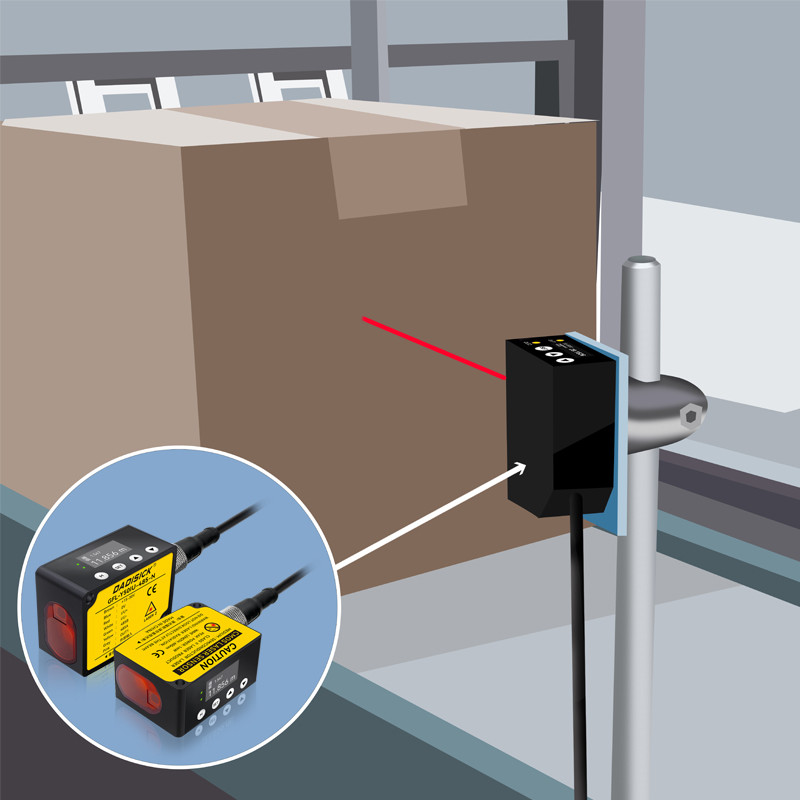

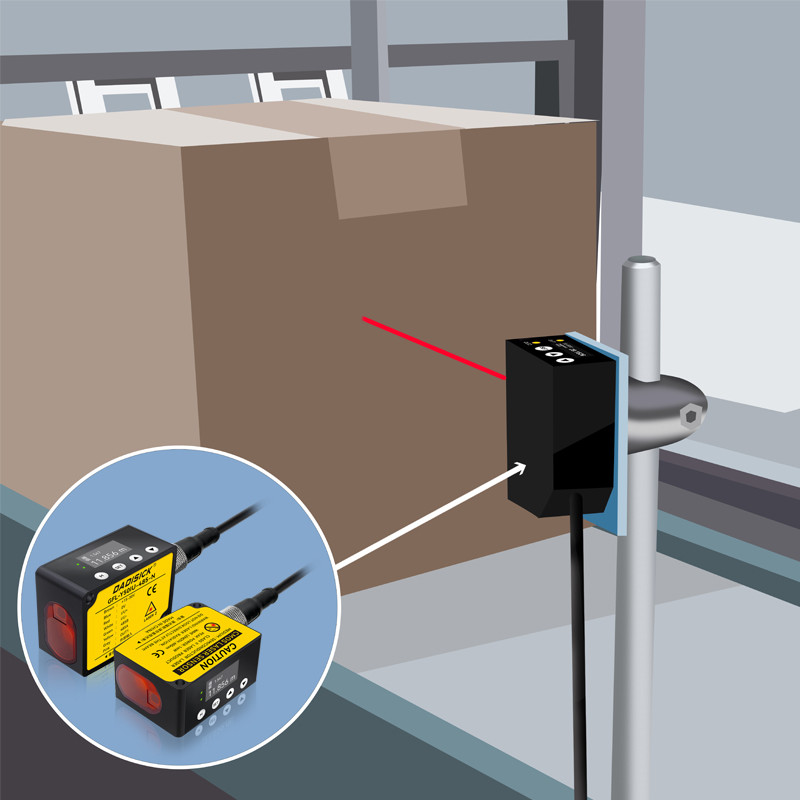

In the packaging process of factories, to ensure the continuous operation of packaging machines, laser distance sensors are widely used for monitoring the material level in carton warehouses.

Basic Principle of Laser Distance Sensors

Laser distance sensors work by emitting a laser beam and receiving the reflected signal, measuring the time taken for the laser to travel from emission to reception, and calculating the distance between the sensor and the target object based on the speed of light. This non-contact measurement method maintains high accuracy and stability in various industrial environments. Regardless of the color of the cartons, laser distance sensors are unaffected by light reflection and ambient light, ensuring stable measurements.

The Role of Laser Distance Sensors in Carton Warehouse Level Monitoring

Real-time Level Monitoring:

Based on the direction of the carton warehouse discharge, laser distance sensors can be installed above or in front of the side of the warehouse to measure the stacking height (level) of cartons in real-time. By comparing it with preset thresholds, the system can accurately determine whether the carton stock is sufficient or if it is nearing the storage limit, thereby triggering replenishment or relocation operations in time.

Improving Production Efficiency:

By monitoring material levels in real-time, it is possible to avoid production downtime caused by insufficient stock and prevent excessive stock from occupying storage space. Combined with automated control systems, laser distance sensors can also automatically trigger replenishment or relocation commands, reducing manual intervention and increasing production efficiency.

Ensuring Production Safety:

Laser distance sensors can also monitor the stability of carton stacks, preventing collapse accidents caused by excessively high or tilted stacks. When the sensor detects an abnormal stack, it can immediately issue an alarm, prompting operators to take appropriate measures to ensure production safety.

Technical Advantages of Laser Distance Sensors

✅ High Accuracy: Measurement error within ±(2 mm + d * 0.0001)★

✅ Long-Range Measurement: Suitable for carton warehouses of various sizes. DADISICK’s GFL-F Series and DA-Y & DB-Y Series laser measurement sensors can measure distances of up to 50 meters and 100 meters, respectively.

✅ Non-contact Measurement: Reduces mechanical wear and failure rate between the sensor and the cartons.

High Adaptability: Able to adapt to various environmental and lighting conditions, with sensors offering dustproof and waterproof features, making them suitable for most harsh industrial environments.

✅ High Adaptability: Able to adapt to various environmental and lighting conditions, with sensors offering dustproof and waterproof features, making them suitable for most harsh industrial environments.

★ Explanation:

At speed grade 1, “d” represents the actual distance. Under adverse conditions, such as strong sunlight or large fluctuations in ambient temperature, measurement errors may increase. In such cases, using a target reflector improves performance.

Related Measurement Sensors

Output method: NPN/PNP+analog+RS485

Resolution: 1mm

Laser type: red semiconductor laser Class II laser 655+10nm<1m

Reaction time: 50-200ms

Measure distance: 0.1-50m

Measuring frequency: 1Hz-40Hz

Communication interface: RS232/RS485 (switchable)

Measuring distance: 0.2-100m

Measurement resolution: 1mm

Response time: up to 1.0ms

Repetitive accuracy: up to 2µm

Response time: up to 1.5ms

Repetitive accuracy: up to 10µm