Application of Measuring Light Curtain in Metal Plate Punching Detection and Coil Cutting Positioning

- Share

- publisher

- Vicky

- Issue Time

- Sep 24,2024

Summary

The application of measuring light curtains in metal plate punching, coil cutting positioning and hole detection has greatly improved production accuracy and efficiency. Its non-contact and high-precision characteristics make it an important tool in modern manufacturing. In the future, with the advancement of automation, measuring light curtains will promote the development of industry towards intelligence and precision, helping companies maintain their advantages in competition.

In modern manufacturing, the processing accuracy of metal sheets and coils is a key factor affecting product quality. The lack of punching, the error of cutting positioning and the presence of holes in the sheet will directly affect the performance and appearance of the final product. In order to ensure the accuracy of each link in the production process, the application of measuring light curtains has gradually become an industry standard.

Measuring Light Curtains for Missing Punch Holes

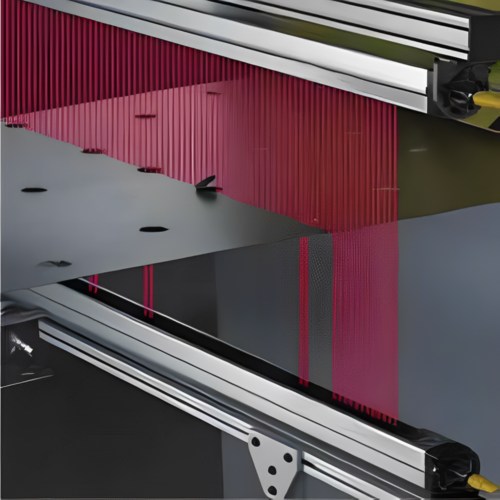

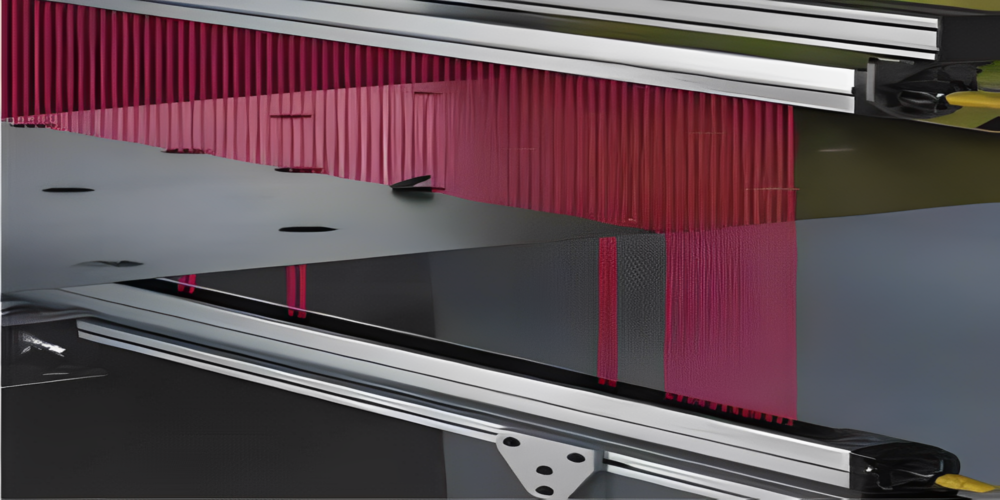

In the stamping process of metal plates, the accuracy of punching is crucial. The measuring light curtain forms a precise spot network through a multi-beam infrared LED transmitting and receiving system. When the metal plate passes through the detection area, the light curtain can quickly capture the position and size of each hole on the plate. Once a punching hole is missing or does not reach the standard size, the light curtain will immediately trigger an alarm signal to prevent defective products from flowing into the next processing link. This real-time detection greatly improves production efficiency and reduces rework and waste.

Measuring Light Curtains for Precise Positioning of Coil Cutting

In the coil cutting process, positioning accuracy is the key to ensure cutting quality. The measuring light curtain forms a high-precision beam network in the cutting area to monitor the position and movement trajectory of the coil in real time. The cutting tool is adjusted according to the positioning data fed back by the light curtain to ensure that each cut is completed at the predetermined position. Even in high-speed production lines, the light curtain can ensure cutting accuracy and consistency, avoiding the impact of cutting errors on production progress and quality.

Safety Light Curtain Detection of Plate Holes

In some production applications, holes in the sheet may cause product performance degradation or failure. The high-precision detection capability of the measuring light curtain enables it to quickly identify holes or irregular shapes in the sheet and provide real-time feedback to the control system. By linking with other detection equipment, the measuring light curtain can automatically remove defective sheets from the production line, ensuring that only qualified products enter the next processing link. This non-contact detection method not only increases the detection speed, but also reduces manual intervention, further optimizing the production process.

Application Advantages of Measuring Light Curtains

The core advantage of the measuring light curtain in these applications lies in its high precision and high-speed response capability. Compared with traditional mechanical detection methods, the measuring light curtain can complete the detection without contacting the plate, avoiding damage to the surface of the material. At the same time, the multi-beam design of the light curtain ensures the coverage of large-area detection, whether it is detecting punching, cutting positioning, or plate holes, it can be accurate and error-free.

In addition, the easy integration of the measuring light curtain enables it to be easily connected to the existing automated production line, reducing the complexity of system transformation. For enterprises with large-scale production, the application of measuring light curtains not only improves production efficiency, but also reduces production costs.

The Future of Measuring Light Curtains

With the continuous advancement of industrial automation technology, measuring light curtains will play a key role in more application scenarios. Especially in the context of intelligent manufacturing and Industry 4.0, measuring light curtains, as key detection equipment, will bring more innovation and optimization space to the processing of metal sheets and coils. In the future, it will not only be limited to detection, but may also be combined with intelligent analysis systems to achieve real-time monitoring and optimization of the entire production process.

In short, the application of measuring light curtains in metal plate punching, coil cutting and positioning, and plate hole detection has significantly improved the accuracy and efficiency of production. Its non-contact and high-precision features make it an indispensable testing tool for modern manufacturing. In the future of automated production, measurement light curtains will continue to promote the development of industrial production in the direction of intelligence and precision, helping enterprises to remain invincible in the fierce market competition.

DADISICK's Hot Selling Safety Light Curtains

Beam spacing: 20mm

Number of optical axes: 22

Protection height: 420mm

Beam spacing:200mm

Number of optical axes: 12

Protection height: 2200mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing: 40mm

Number of optical axes: 20

Protection height: 760mm

Safety light beam outputs (OSSD)2 PNP

Beam spacing:40mm

Number of optical axes: 54

Protection height: 2120mm

Safety Curtain outputs (OSSD):2 PNP