Application of Measuring Light Curtain in Tire Sorting: Accurate and Efficient, Leading Intelligent Manufacturing

- Share

- publisher

- Vicky

- Issue Time

- Sep 21,2024

Summary

The application of measuring light curtains in tire classification has greatly improved the technical level.Through precise inner and outer diameter dimension detection and automated classification, the light curtains effectively improve production efficiency, reduce costs, and ensure product quality. In the future, measuring light curtains will play an important role in tire production and more industrial fields, promoting the industry to develop in the direction of intelligence and automation.

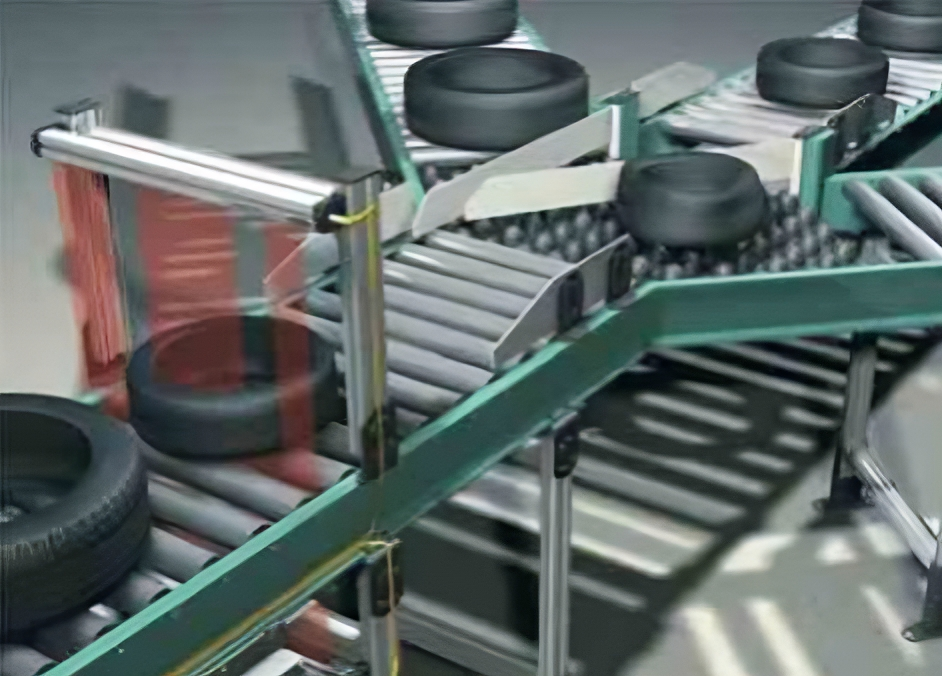

In the modern tire production and sorting process, accurate size detection is essential to ensure product quality and optimize production efficiency. Traditional manual inspection methods are not only time-consuming, but also prone to errors. The introduction of measuring light curtain technology has greatly improved the automation of tire sorting, helping production lines to improve efficiency while ensuring accuracy. This article will introduce how measuring light curtains play a role in tire sorting.

Working Principle of Two Measuring Light Curtain Detection Systems

In tire sorting applications, two measuring light curtain systems are used to detect the inner and outer diameters of tires. Each measuring light curtain consists of a series of precisely arranged infrared transmitters and receivers that capture tire size data by scanning the tire surface. Every time a tire passes through the light curtain, the light curtain will determine the inner and outer diameters of the tire through the interrupted light beam.

The two sets of light curtains work together. Once the inner and outer diameter data of the tire are accurately measured, the system will convey the tire to the corresponding conveyor belt according to the preset classification standards. If the detected tire size does not meet any specification standards, the system will automatically remove the tire to prevent unqualified products from entering the packaging stage. This real-time detection and automated classification greatly reduces the need for human intervention and ensures the continuity and accuracy of production.

Application Advantages of Measuring Light Curtains

High-precision detection

The measuring light curtain can quickly and accurately detect the size data of the tire without touching the tire surface, avoiding the wear or error problems caused by traditional mechanical measurement. Through non-contact detection, the light curtain can also effectively avoid tire surface contamination and improve product quality.

Improve production efficiency

Through the automated sorting system, tires can be quickly diverted to different conveyor belts on the production line, reducing the need for manual intervention and greatly improving production efficiency. The high-speed detection of the measuring light curtain ensures the smooth operation of the production line.

Reduce production costs

The measuring light curtain not only reduces the need for manual inspection, but also prevents unqualified tires from entering the next production or packaging process through precise size screening, thereby reducing the possibility of rework and material waste.

Automatic rejection of unqualified products

The system automatically identifies tires whose sizes do not meet the specifications and removes them from the production line, ensuring the quality of the final product while optimizing the use of resources.

Application Prospects of Measuring Light Curtains

As the automation level of tire production lines continues to improve, measuring light curtain technology will play a role in more production scenarios. In the future, with the further development of intelligent manufacturing, measuring light curtains can not only be used for tire classification, but also integrate more functions, such as real-time data monitoring, quality feedback, etc., to help companies achieve all-round production optimization.

DADISICK's Hot Selling Safety Light Curtains

Beam spacing: 20mm

Number of optical axes: 40

Protection height: 780mm

Beam spacing: 10mm

Number of optical axes: 102

Protection height: 1010mm

Safety curtain outputs (OSSD): 2 PNP

Beam spacing:40mm

Number of optical axes: 20

Protection height: 760mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing:40mm

Number of optical axes: 54

Protection height: 2120mm

Safety Curtain outputs (OSSD):2 PNP