Application of Measuring Light Curtains to Count Small Flat Objects That Fall

- Share

- publisher

- Vicky

- Issue Time

- Sep 23,2024

Summary

The measuring light curtain has become an indispensable counting tool in modern industrial production with its high-precision spot synchronization multi-beam infrared LED technology and accurate detection of extremely small objects. It provides technical support for efficient and safe production, and will play an important role in more industrial scenarios in the future, helping enterprises to achieve intelligent and automated production.

In modern industrial production, efficient and accurate counting and detection of small objects is an important part of improving production efficiency and quality control. Especially when counting extremely small and flat objects, traditional detection methods often have problems such as low accuracy and missed detection. In response to these challenges, the use of measuring light curtain technology can greatly improve the accuracy and efficiency of counting, especially through the unique spot synchronization multi-beam infrared LED technology to achieve high-precision detection.

Advantages of Spot Synchronization Technology

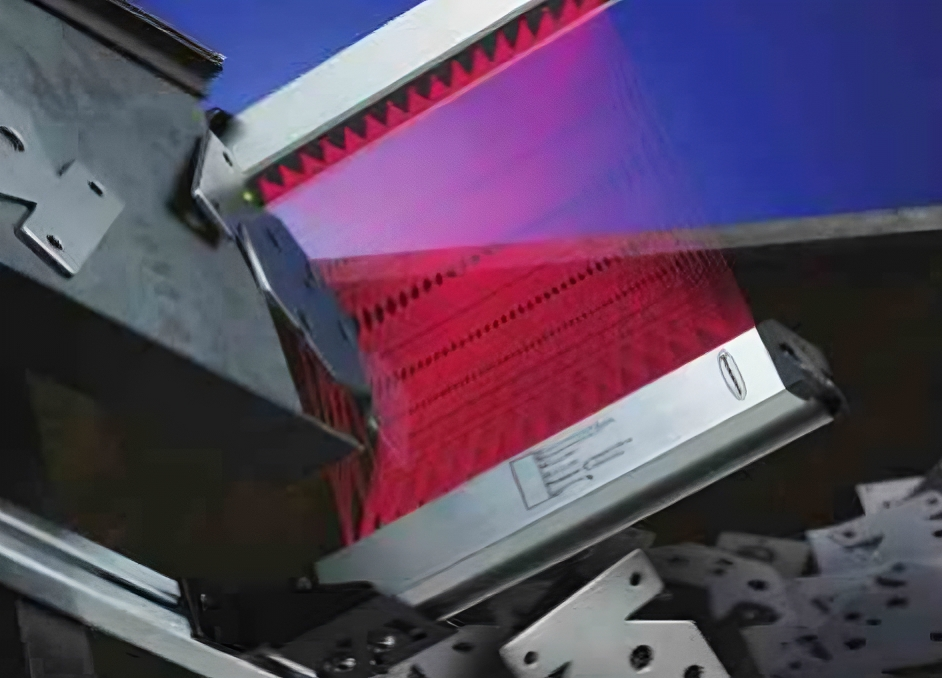

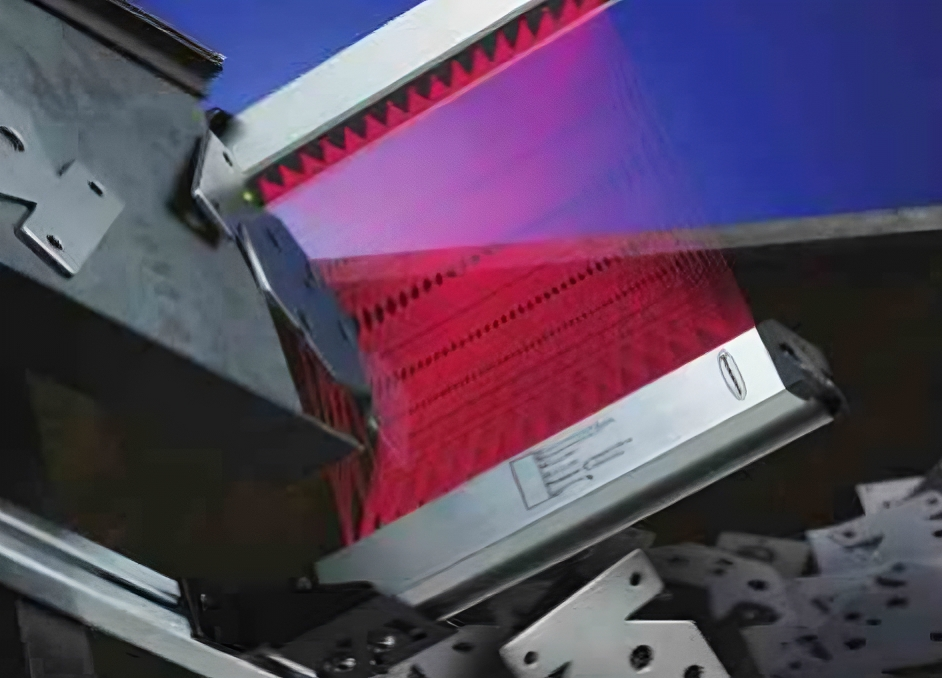

The measuring light curtain uses a multi-beam infrared LED transmitting and receiving system, which can produce precise light cross spots. When a small flat object falls, it will block part of the light and trigger the detection signal of the light curtain. This spot synchronization technology ensures that multiple beams work at the same time, avoiding the problem of missed detection that may exist in single-beam detection. Especially for small flat objects with irregular shapes, such as electronic components or small plastic products, cross light can more accurately capture the movement trajectory of the object and achieve full coverage detection without blind spots.

Measuring the Detection Capability of Light Curtains for Extremely Small Objects

The ability to detect extremely small objects is a core advantage of the measuring light curtain in high-precision applications. Thanks to the high-density beam arrangement and fine light cross-spots, the light curtain can detect objects as small as millimeters falling. This ability to detect extremely small objects makes it very suitable for counting small metal pieces, flat electronic parts, etc., ensuring that each object can be accurately counted to prevent missed detection and miscounting.

Application Scenarios and Advantages of Measuring Light Curtains

Measuring light curtain technology is widely used in various scenarios that require high-precision object counting, such as small parts sorting in automated production lines, product quantity detection in the packaging process, and quality control in the production process. In these scenarios, the falling count of small flat objects is crucial to the optimization of the production process.

By measuring the precise detection of light curtains, the following advantages can be achieved:

Improve production efficiency

Fast and accurate counting reduces human intervention and improves overall production efficiency.

Reduce errors

Multi-beam infrared LED technology ensures the stability and accuracy of detection, avoiding missed detection and wrong counting.

Reduce operating costs

Automated detection and counting functions reduce human involvement, reducing the error rate and cost in the production process.

Diversified applications

The light curtain can be adjusted according to different production needs and is suitable for counting various types of flat small objects with high flexibility.

DADISICK's Hot Selling Safety Light Curtains

Beam spacing: 20mm

Number of optical axes: 20

Protection height: 380mm

Beam spacing:20mm

Number of optical axes: 40

Protection height: 780mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing: 40mm

Number of optical axes: 20

Protection height: 760mm

Safety light beam outputs (OSSD)2 PNP

Beam spacing:40mm

Number of optical axes: 54

Protection height: 2120mm

Safety Curtain outputs (OSSD):2 PNP