Application of QT Series Safety Light Curtains in Safety Protection of Robot Work Units

- Share

- publisher

- Vicky

- Issue Time

- Sep 18,2024

Summary

The application of safety light curtains in robot work units provides reliable protection for safety in industrial automation. Through its non-contact and efficient protection method, it effectively prevents safety accidents during operation and provides important support for safe production in modern intelligent manufacturing.

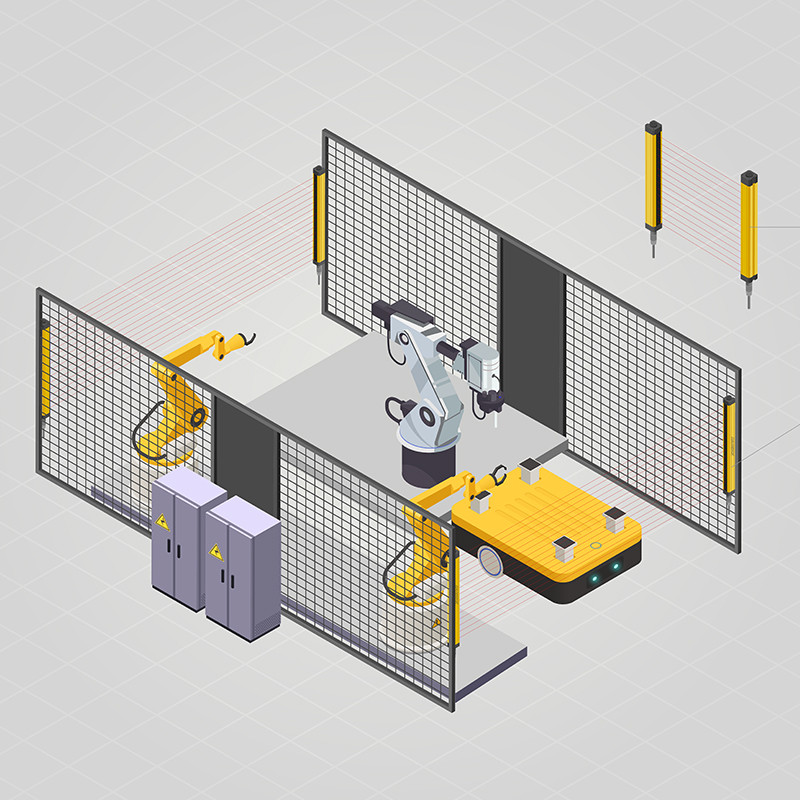

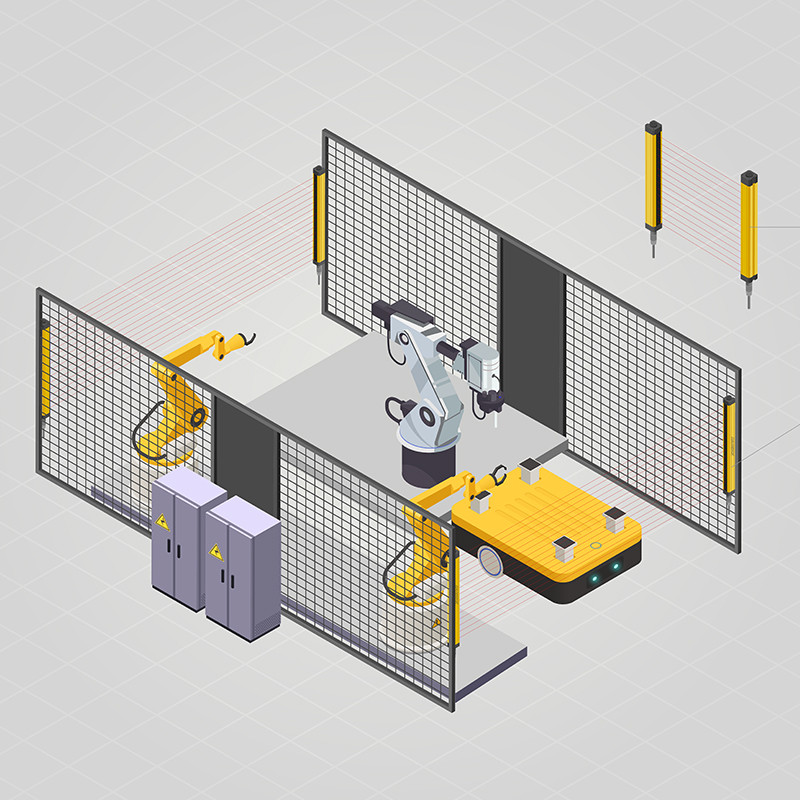

With the rapid development of industrial automation and robotics, robotic work units have become an indispensable part of modern manufacturing. However, the potential safety risks during robot operation have also increased. In order to ensure the safety of operators, safety light curtains, as an efficient and reliable protective device, play an important role in the safety protection of robotic work units.

Working Principle of Safety Light Curtain

The safety light curtain consists of a transmitter and a receiver, which forms an invisible protection area by emitting infrared beams. When the beam is interrupted by an object or a person, the system will immediately stop the operation of the machine or trigger the safety mechanism to avoid accidents. This non-contact protection method is particularly suitable for the safety protection of robot work units.

Application of Safety Light Curtains in Robot Work Units

Robotic work units usually involve mechanical arms and other automated equipment, which operate at high speed and precision. If an operator mistakenly enters the work area, it may cause a serious safety accident. By installing a safety light curtain, the danger zone can be monitored in real time and the shutdown protection can be triggered when someone enters to prevent people from being hurt.

Dangerous area isolation

Install a safety light curtain around the robot's work unit to form a safety protection zone. When a person approaches or enters the area, the robot will automatically stop running to ensure the safety of the person.

Non-contact protection

The safety light curtain uses photoelectric sensors to achieve non-physical contact safety protection, which will not interfere with the normal operation of the machine and is suitable for those occasions that require frequent entry into the work area.

Flexible configuration

The safety light curtain can be flexibly configured according to the specific work unit layout to meet the protection needs of different types of robots.

Advantages of QT Series Light Curtains

Efficient response

The safety light curtain can respond instantly when it detects people or objects entering the dangerous area, triggering shutdown or other safety measures to ensure safety.

Customizable

The height, width and sensitivity of the safety light curtain can be adjusted according to the robot's operating space and workflow, suitable for various industrial environments.

Improve production efficiency

The safety light curtain can ensure the safety of personnel while avoiding the inconvenience caused by traditional mechanical guardrails, thereby improving production efficiency.

Future Prospects of Safety Light Curtains

With the further improvement of robot technology and automation level, the application of safety light curtains in robot work units will become more extensive and intelligent. In the future, intelligent safety light curtains will be deeply integrated with robot control systems to provide more flexible and efficient safety protection solutions.

DADISICK's Hot Selling Safety Light Curtains

Beam spacing:20mm

Number of optical axes: 40

Protection height: 780mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing: 10mm

Number of optical axes: 102

Protection height: 1010mm

Safety curtain outputs (OSSD): 2 PNP

Beam spacing: 40mm

Number of optical axes: 32

Protection height: 1240mm

Safety sensors for machines outputs (OSSD)2 PNP

Beam spacing:40mm

Number of optical axes: 54

Protection height: 2120mm

Safety Curtain outputs (OSSD):2 PNP