Application of the DS Series Long-Distance Laser Rangefinder in Hook Bridge Cranes

- Share

- publisher

- Zoe

- Issue Time

- Dec 27,2024

Summary

The DS Series Long-Distance Laser Rangefinder can non-contact, quickly, and accurately measure the distance to moving system components. Within just a few milliseconds, the laser measurement system provides the position data required for dynamic control functions via a range of industrial Ethernet and fieldbus interfaces, with millimeter-level precision.

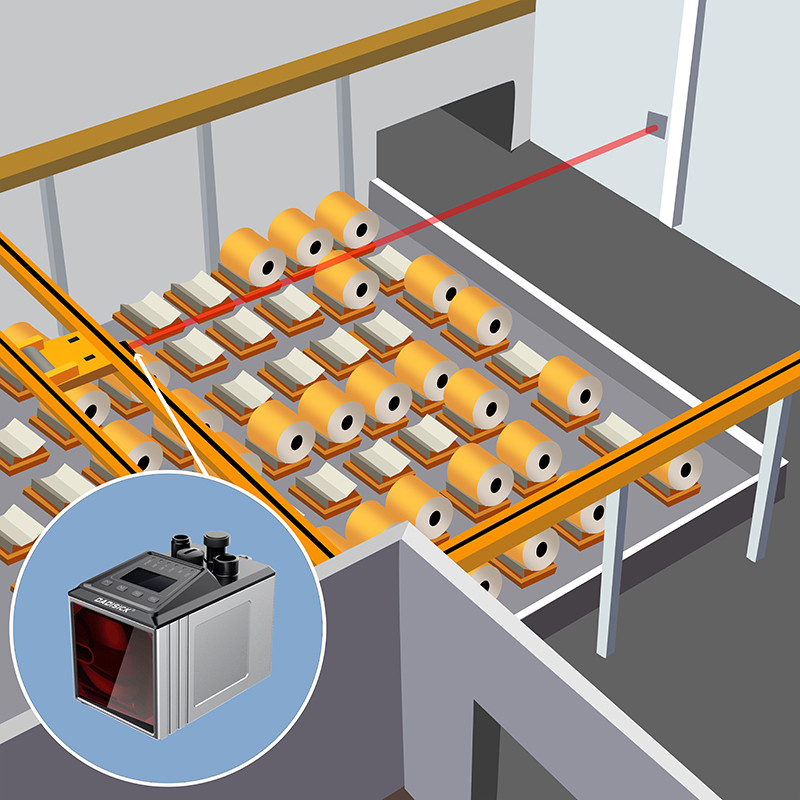

Application of the DS Series Long-Distance Laser Rangefinder in Hook Bridge Cranes

Overview of the Bridge Crane Operation for Handling Finished Steel Products:

1. Position Adjustment of the Lifting Machinery: A bridge crane typically consists of a bridge, trolley running mechanism, hoist, and lifting mechanism. Before starting work, the bridge is adjusted to the approximate work area position via the trolley running mechanism. The trolley can move laterally along the bridge's tracks, while the hoist’s hook moves vertically on the trolley. This allows all parts of the crane to work together and adjust to the proper initial position, ready for lifting operations.

2. Lifting of Goods: Once the crane reaches the vicinity of the target area, the operator uses the control system to move the trolley above the load. The hook is then lowered to the required lifting position, and the lifting tools (such as steel ropes, hooks, etc.) are securely connected to the load.

3. Lifting the Load: After the hook is securely attached to the load, the operator uses the control system to start the lifting mechanism, causing the hook to gradually lift the load until it clears the ground and reaches a safe lifting height.

4. Transporting the Load: Once the load is lifted to the desired height, the operator uses the control system to move the trolley along the bridge’s tracks, transporting the load horizontally from the starting position to the target position.

5. Lowering the Load: Upon reaching the target position, the operator uses the control system to lower the hook and gently place the load at the target location.

6. Completing the Task: Once the load is securely placed, the operator stops all crane operations, completing the lifting task.

Solution:

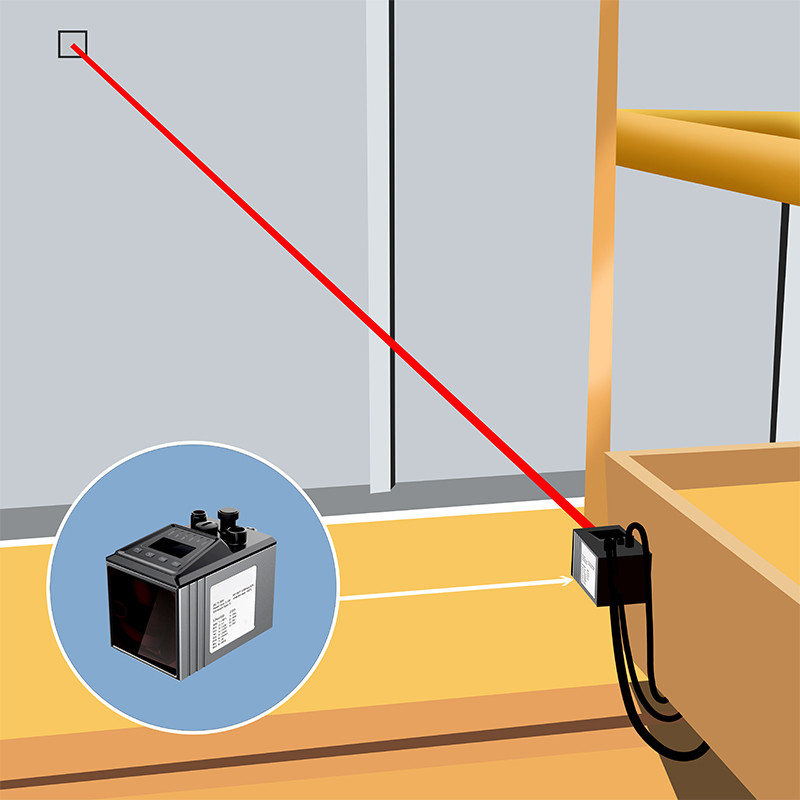

The DS Series Long-Distance Laser Rangefinder is installed on the main beam of the crane. The sensor emits a laser beam and measures the time difference of the reflected light to precisely calculate the distance between the sensor and the reflector. The measured distance data is transmitted in real-time to the crane’s control system. The control system uses this data to accurately calculate the current position of the hook and the deviation from the target position, enabling precise movement and positioning of the crane.

Related Products

Measuring frequency: 1000Hz

Data transmission interface: SSl, Ethernet 100 BASE-TX

Measuring distance: 200m

Measurement accuracy: ±2 mm

Eective transmission distance: 200 m

Communication rate: 100 Mbit/s

Communication light divergence angle: 1°

Communication light receiving angle: 1.5°

Measuring frequency: 1Hz-40Hz

Communication interface: RS232/RS485 (switchable)

Measuring distance: 0.2-100m

Measurement resolution: 1mm

Output method: PNP+analog+RS485

Resolution: 1mm

Laser type: red semiconductor laser Class II laser 655+10nm<1m

Reaction time: 50-200ms

Measure distance: 0.1-50m