Application of the Wide Scanning Range Light Curtain in Industrial Automation Production Line

- Share

- publisher

- Vicky

- Issue Time

- Oct 8,2024

Summary

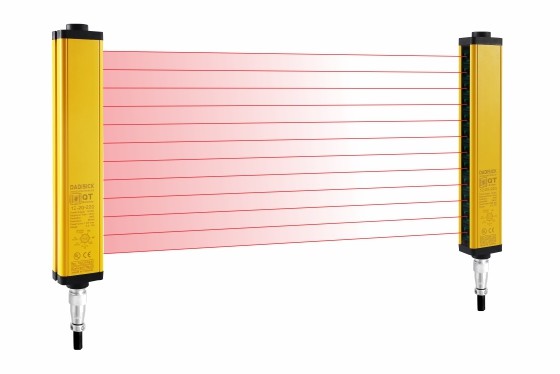

The Wide Scanning Range Light Curtains play an important role in equipment safety, personnel protection and production efficiency improvement. It can achieve all-round safety protection and quickly respond to abnormal situations, providing reliable safety protection for the modern manufacturing industry. With the development of industrial automation, the application of the wide scanning range light curtains will become more extensive and become an important part of intelligent manufacturing

Scenario Overview of the Wide Scanning Range Light Curtain

As can be seen from the picture, the conveyor belt is full of fixtures and workpieces, which are used to fix materials and facilitate the robot arm to accurately grasp or perform further operations. The complex movement of the robot arm and the continuous operation of the conveyor belt greatly improve production efficiency. The multiple wiring beside the equipment, especially the yellow and black cables, indicate that these systems not only require a stable power supply, but also require complex signal transmission to control the robot arm, sensors and other automation devices.

In such a highly automated scenario, safety protection is particularly important. Due to the high speed of the equipment, there are potential dangers in the movement of workpieces and tools. How to ensure that personnel are not harmed when approaching these fast-moving equipment has become a major problem in the production process. This is why safety light curtains with long-distance protection are widely used in such environments and play an important role.

Application of the Wide Scanning Range Light Curtains in Metal Processing Machine Tools

In this scenario, the wide scanning range light curtains form an invisible "safety barrier" around the equipment to achieve real-time monitoring of people and objects. When an operator approaches a dangerous area or an object accidentally enters the working area of the equipment, the light curtain will immediately detect and send a stop signal to ensure that the equipment stops running and avoid accidents. The following discusses its application in detail from several aspects:

Safety protection of robotic arms

In industrial automation production lines, robotic arms undertake tasks such as high-precision material handling, assembly, and welding. Due to the complex motion path of the robotic arm and high precision requirements, any external interference will lead to misoperation or equipment damage, or even personal injury. The wide scanning range light curtain can be set in the working area around the robotic arm to prevent operators from accidentally entering the range of motion of the robotic arm. When the safety light curtain detects that someone or other objects have entered the dangerous area, the system will immediately stop the movement of the robotic arm to avoid collision or misoperation.

Protection of the conveyor belt system

The conveyor belt is a key component in the production line, responsible for moving workpieces or products from one processing point to the next. The continuous operation of the conveyor belt is dangerous, especially when materials or tools fall, which may cause equipment failure or personal injury. The wide scanning range light curtains can be arranged on both sides or above the conveyor belt. When a foreign object is detected falling into the conveyor belt, the light curtain will send a signal to stop the operation of the conveyor belt to ensure the safety of equipment and personnel.

Protection of workpieces and fixtures

On the production line, fixtures are used to fix workpieces to ensure their stability and precision on the robot arm or conveyor belt. However, in an efficient operation environment, the displacement of workpieces or the failure of fixtures will bring safety hazards. The multi-faceted protection function of the safety light curtain can monitor these areas in all directions. Once it is detected that the fixture fails to properly fix the workpiece or the workpiece accidentally falls off, the system will respond immediately to prevent the equipment from continuing to operate and causing accidents.

Protection of lines and control systems

As can be seen in the figure, a large number of power lines and control lines are arranged next to the equipment. These lines provide power and signal transmission for the equipment's sensors, controllers, robot arms, etc. The wide scanning range light curtain protection can monitor the safety status of these cables to prevent people or materials from accidentally touching the cables or damaging the lines, which may cause equipment shutdown or safety accidents.

Advantages of the Wide Scanning Range Light Curtain

Long-distance coverage

The wide scanning range light curtains have a wide coverage range and can easily monitor a large area of the entire automated production line. This is particularly applicable to production lines with a wide distribution of robotic arms, conveyor belts and other automated equipment, reducing the use of traditional mechanical guards and improving work flexibility and safety.

High-speed response and real-time detection

The wide scanning range light curtains have a high-speed response capability, which can detect intrusion objects in a very short time and send a shutdown signal. Such a fast response is essential to ensure the safety of mechanical equipment and personnel, especially when the production line is running at high speed, to avoid accidents.

Non-contact protection

Compared with traditional mechanical guards, the wide scanning range light curtains use a non-contact photoelectric detection method, which does not cause any physical obstruction to the normal operation of the equipment. This non-contact protection not only ensures the continuous and efficient operation of the equipment, but also improves operational flexibility.

Multi-faceted monitoring and flexible layout

Modern industrial automated production lines usually have multi-dimensional workspaces, and the wide scanning range light curtains can provide protection in multiple directions as needed. Whether it is on the front, side or top of the production line, the light curtain can be flexibly arranged to maximize coverage of the dangerous area.

Application Case Demonstration of the wide scanning range light curtain

The video shows an industrial automation production line, where multiple robotic arms and conveyor belts together form a highly automated working environment. The equipment in the video has a large number of sensors, control systems, and power supply wiring, reflecting the highly sophisticated characteristics of current industrial production. In such a production scenario, the application of the wide scanning range light curtains are particularly important to ensure the safety and efficiency of the production process.

Recommended the Wide Scanning Range Light Curtain Features

This safety light curtain is designed for automated facilities and high-risk mechanical operation areas. Its key feature is maintaining a reliable connection within a 45-meter range, particularly suitable for complex operating environments. The robust casing ensures impact resistance, ensuring stable operation in various conditions. The product undergoes comprehensive testing to guarantee high performance and reliability.

The Wide Scanning Range Light Curtain Features

The protection distance between the transmitter and the receiver can reach 45m, without fear of environmental interference.

Each set of DADISICK light curtains will undergo product reliability tests including: PCBA vibration test, life stability test (YD/T 644-93), electrical performance testing, impact test, waterproof and dustproof test, anti-interference test and other projects .

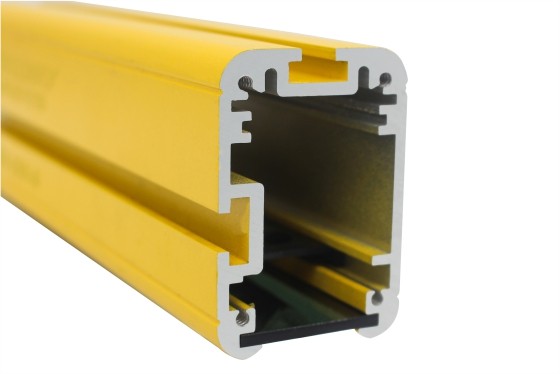

The aluminum alloy shell is strong, the structure is stable, and the shockproof performance is excellent. The slider groove design on the back allows a variety of installation methods to be selected according to the product fixing direction.

Recommended Safety Light Curtains

Beam spacing: 200mm

Number of optical axes: 10

Protection height: 1800mm

Safety Curtain outputs (OSSD): 2 PNP

Beam spacing:20mm

Number of optical axes: 20

Protection height: 380mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing:40mm

Number of optical axes: 20

Protection height: 760mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing:40mm

Number of optical axes: 54

Protection height: 2120mm

Safety Curtain outputs (OSSD):2 PNP