Basic Concepts and Working Principles of Safety Light Curtains

- Share

- publisher

- Vicky

- Issue Time

- Aug 22,2024

Summary

Safety light curtain is a photoelectric device that detects people or objects entering dangerous areas by emitting and receiving infrared beams, and triggers emergency shutdown or other safety measures when necessary to protect the operator. It is widely used in industrial automation scenarios, with the advantages of efficient protection, non-contact protection and high flexibility, effectively reducing the risk of accidents.

Safety light curtains are photoelectric devices used in industrial automation and mechanical safety protection, and are widely used in scenarios where operators need to be protected from mechanical equipment. Their main function is to detect the entry of people or objects through light beams, and trigger emergency shutdown or other safety measures when necessary, thereby preventing potential dangers.

Basic Concepts of Safety Light Curtains

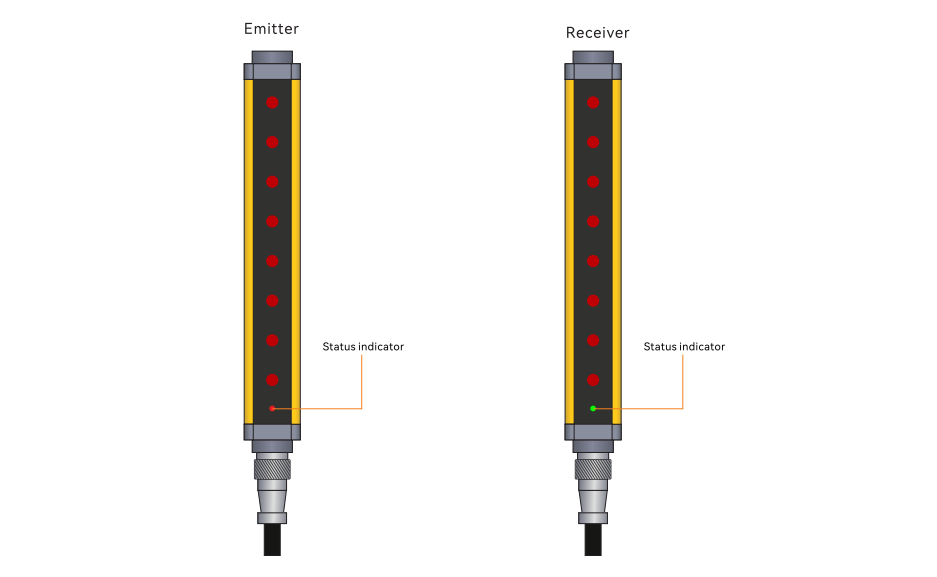

Safety light curtains consist of two main parts: an emitter and a receiver. The emitter emits a series of invisible infrared beams that cover the area to be protected in parallel. The receiver is located opposite the emitter and is used to receive these beams.

When all the emitted beams reach the receiver, the system assumes that there are no obstacles or people entering the protection area and the equipment can operate normally. Once an object or person enters the protection area and blocks the beam, the receiver cannot receive the complete beam signal, and the system will respond immediately, such as triggering a shutdown command for the equipment, thereby protecting people entering the area or preventing damage to the equipment.

Working Principle of Safety Light Curtain

Beam emission and reception

The transmitter continuously emits multiple parallel infrared beams, which form a dense light grid. The receiver receives these beams and transmits the signal to the control system. Under normal circumstances, all beams can reach the receiver, which means that there are no obstacles or personnel in the protection area.

Detection process

When a person or object enters the area covered by the safety light curtain, part or all of the beams are blocked. The receiver detects the interruption of the beam and transmits this abnormality to the control unit.

Signal processing and response

The control unit processes the signal transmitted by the receiver. If a signal of beam interruption is detected, the system will immediately trigger the preset safety measures, such as stopping the machine, sounding an alarm, or other control actions related to stopping the equipment.

Resuming normal operation

Once the obstacle or person leaves the safety light curtain area, the beam is received by the receiver again, and the control system allows the equipment to continue to operate, or restarts the equipment after confirming safety.

Applications and Advantages of Safety Light Curtains

Safety light curtains are widely used in places where operators need to frequently approach dangerous machinery and equipment, such as automated production lines, mechanical processing, packaging equipment, and industrial robot work areas. Its main advantages include:

Efficient protection

It can quickly detect the entry of people or objects and respond instantly to ensure the safety of operators.Non-contact protection

Compared with traditional mechanical safety protection measures, safety light curtains do not require direct contact with people or objects, greatly reducing the risk of misoperation.High flexibility

The height, beam density and other parameters of the safety light curtain can be adjusted according to the specific application scenario, suitable for various complex working environments.DADISICK's Hot Selling Safety Light Curtains

Beam spacing: 80mm

Number of optical axes: 46

Protection height: 3600mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing:40mm

Number of optical axes: 42

Protection height: 1640mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing: 40mm

Number of optical axes: 32

Protection height: 1240mm

Safety sensors for machines outputs (OSSD)2 PNP

Beam spacing: 10mm

Number of optical axes: 164

Protection height: 1630mm