How Does a Safety Light Curtain Work with a Safety Relay?

- Share

- publisher

- Vicky

- Issue Time

- Sep 13,2024

Summary

When the safety light curtain works with the safety relay, the combination of safety light curtain and safety relay forms a reliable and safe protection mechanism, which is widely used in industrial automation, mechanical processing and other fields to ensure the safety of operators and improve production efficiency.

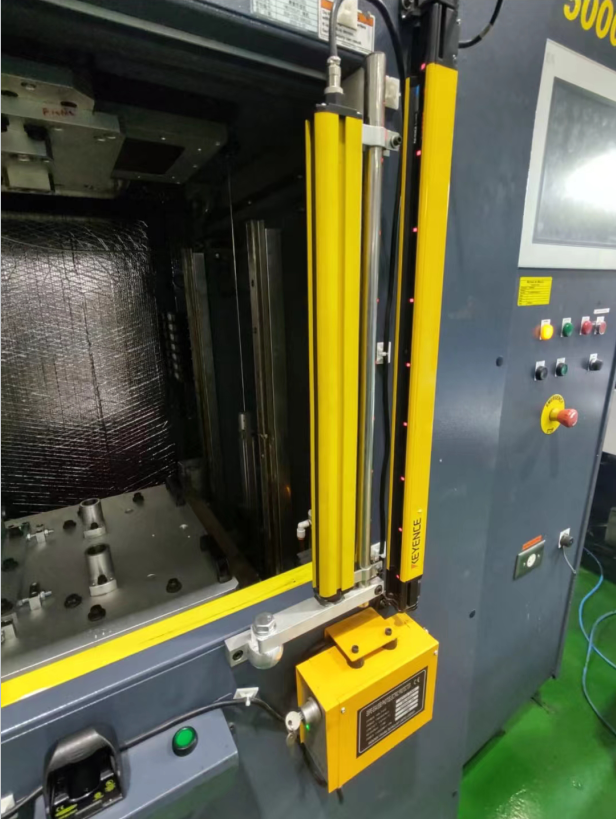

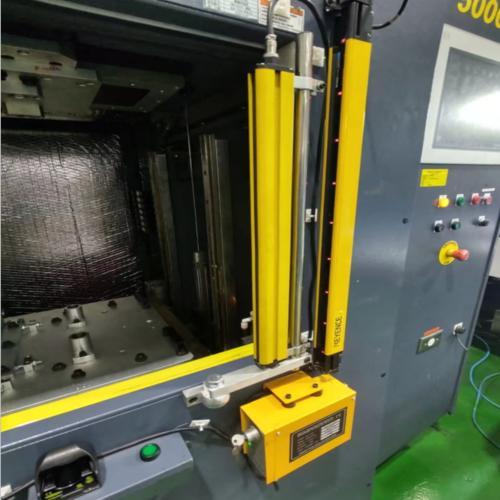

When the safety light curtain works with the safety relay, a complete safety protection system is formed to protect operators from harm from mechanical equipment. Its working process is as follows:

Safety Light Curtain Transmission and Reception

Light curtain transmission and reception: The safety light curtain consists of a transmitter and a receiver. The transmitter sends out a series of infrared beams, and the receiver detects these beams. If the beams are not blocked, the system assumes that there are no obstacles in the operating area and the equipment is operating normally.

Beam Break Detection for Safety Light Curtains

When a person or object enters the area covered by the safety light curtain, the infrared beam is interrupted. The receiver immediately senses the interruption of the beam and sends a signal to the safety relay.

Safety Relay Processes Safety Light Curtain Signal

After the safety relay receives the interrupt signal from the light curtain, it will process it according to the preset safety logic. The safety relay contains redundant circuits or dual-channel designs to increase the reliability and safety of the system.

Dual-channel redundancy check

Safety relays usually adopt a dual-channel design to ensure that even if one circuit fails, the other circuit can still work normally. It cross-verifies the signal to determine whether there is a real safety hazard.

Signal delay judgment

The relay can confirm the signal within a specified time. If the light curtain is temporarily blocked (such as an unexpected object passing by), the relay may not immediately trigger a shutdown, but judge according to the preset time parameters.

Safety Measures for Safety Relays to Trigger Safety Light Curtains

Once the safety relay confirms that there is a safety hazard, such as a beam interruption that cannot be restored, the system will execute the predetermined safety response measures. This usually includes:

Emergency stop

Immediately stop the operation of the equipment to prevent further danger.

Power off

Cut off the power supply to the machine to ensure that the equipment cannot operate at all.

Alarm trigger

Sound a warning sound or signal light to notify the operator of the potential danger.

System Recovery

Once the obstacle or person leaves the light curtain area, the light beam is restored, the safety relay receives the signal, confirms that the danger is eliminated, and the equipment can be restarted or resumed.

DADISICK's Hot Selling Safety Light Curtains

Beam spacing:40mm

Number of optical axes: 56

Protection height: 2200mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing: 80mm

Number of optical axes: 50

Protection height: 3920mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing: 40mm

Number of optical axes: 32

Protection height: 1240mm

Safety sensors for machines outputs (OSSD)2 PNP

Beam spacing: 10mm

Number of optical axes: 164

Protection height: 1630mm