How Ultrasonic Level Sensors Work and Their Role in Industrial Automation

- Share

- publisher

- Zoe

- Issue Time

- Sep 7,2024

Summary

Liquid level measurement technology plays a vital role in numerous fields and industries, ensuring production safety, improving efficiency, and optimizing product quality. This article discusses ultrasonic level sensors as a common solution for liquid level measurement and explains how they work.

The Importance of Level Measurement in Industrial Automation

Level measurement technology plays a critical role in various fields and industries, ensuring production safety, improving efficiency, and optimizing product quality. This article discusses ultrasonic level sensors as a common solution for level measurement and provides a detailed explanation of how they work.

Chemical Industry:

In chemical production, high or low liquid levels in reactors can lead to safety risks such as fires, explosions, or equipment damage. Therefore, accurate level measurement is crucial for maintaining production safety.Pharmaceutical and Food Industry:

In pharmaceutical and food production, precise level control ensures accurate formulation ratios, which guarantees product quality and stability. Additionally, level measurement helps monitor processes such as mixing and stirring to ensure consistency.Pulp and Paper Industry:

In the paper-making process, level measurement is used to control the concentration and flow of materials such as pulp and water, regulating machine speeds and ensuring smooth production.Water Treatment Industry:

In water treatment plants, including drinking water and wastewater facilities, level measurement monitors the water levels in tanks, ensuring a stable treatment process and maintaining water quality.Apart from these industries, level measurement is also widely applied in agriculture, aquaculture, shipping, and other sectors.

Ultrasonic Level Sensors: A Solution for Level Measurement

Ultrasonic level sensors offer a non-contact solution for real-time liquid level monitoring. They can accurately measure liquid levels without being affected by the liquid's properties. These sensors perform well in various industrial environments, particularly in challenging or harsh conditions. By using ultrasonic level sensors, companies can efficiently control raw material input, prevent waste, and integrate with automation systems to enable automatic feeding or machine shutdown, thus optimizing workflows and increasing productivity.

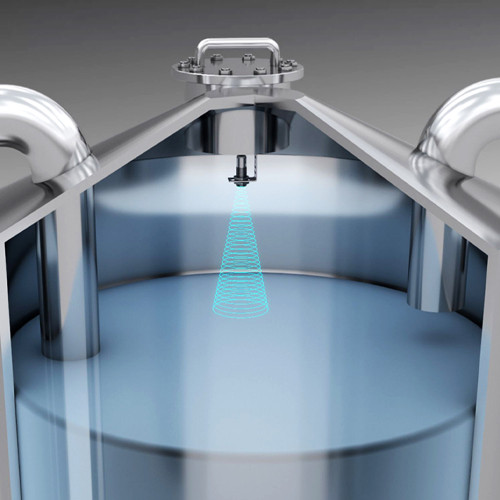

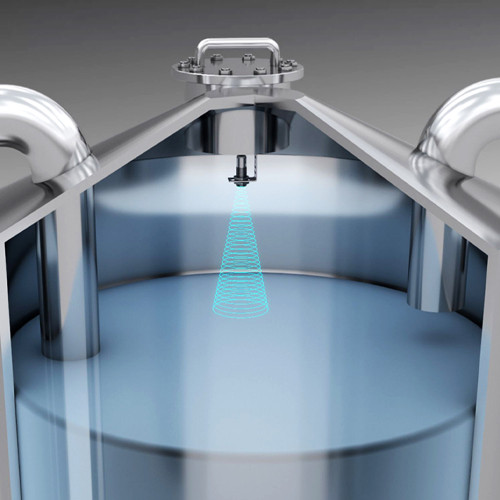

How Ultrasonic Level Sensors Work

An ultrasonic level sensor consists of a transmitter and a receiver. The transmitter emits ultrasonic sound waves, which travel through air (or another medium) to the liquid surface. When the sound waves hit the liquid, part of the energy is reflected back, creating an echo. The receiver captures the reflected sound waves and converts them into an electrical signal.

The sensor’s internal processor calculates the time it takes for the sound wave to travel back and forth. This calculation is based on the known speed of sound (about 340 m/s in air). By determining the distance the sound wave traveled and knowing the distance between the sensor and the bottom of the container, the liquid level can be accurately measured.

Installation of Ultrasonic Level Sensors

Ultrasonic level sensors are typically installed at the top of a container, with the sensor probe facing the liquid surface. However, factors such as foam, dust, or steam can affect the transmission of ultrasonic waves. Therefore, it is essential to carefully select the installation location. These sensors are easy to install and highly adaptable but should be avoided in environments where signal loss is significant.

The Future of Ultrasonic Level Sensors

With the rapid development of Industry 4.0 and smart manufacturing, level measurement technology is increasingly being integrated with the Internet of Things (IoT), big data, and cloud computing, driving intelligent management of production processes. In the future, companies will integrate data from level sensors and other devices to build comprehensive monitoring systems, enabling visualized, traceable production processes and data-driven intelligent decision-making.

Related Ultrasonic Level Sensors

✅ Detection range models: 60 mm - 1000 mm or 150 mm - 2500 mm

✅ Dimension: M18 thread, 55 mm length or M30 thread, 60 mm length

✅ Protection rating: IP67

✅ Connection type: 5-pin M12

✅ Output types: Analog current output 4 - 20 mA, analog voltage output 0 - 10 V, supports RS485 Modbus-RTU

✅ PVDF corrosion-resistant flange probe design, suitable for various corrosive environments

✅ Built-in temperature compensation

✅ Detection distance learning function via gray wire