How to Calibrate the Span of an Overhead Crane Using Laser Distance Sensors?

- Share

- publisher

- Zoe

- Issue Time

- Aug 10,2024

Summary

In the lifting system of a crane, ensuring synchronous precision between components is crucial for maintaining equipment stability, improving operational efficiency, and ensuring operational safety. Laser distance sensors, with their high precision, non-contact measurement, and strong environmental adaptability, are widely used for measuring key parameters of cranes. The following introduces how to use laser distance sensors to measure the crane span.

Applications of Overhead Cranes in Industry

Overhead cranes are widely used in various industrial and commercial settings, including workshops, warehouses, stockyards, ports, logistics centers, construction sites, energy facilities (such as power plants and nuclear power stations), mines, and quarries. Their versatility allows them to meet the lifting and transportation needs of different scenarios.

Overhead cranes are not only used for simple material handling but also play a role in more complex production processes, such as material handling on assembly lines, installation and maintenance of machinery, loading, unloading, and stacking of goods, as well as lifting and installation of construction materials. Additionally, in ports and terminals, overhead cranes are extensively used for loading, unloading, and stacking containers, supporting efficient port operations.

There are various types of overhead cranes, including general overhead cranes and gantry cranes. Although these cranes differ in structure and operation methods, they all operate on a cyclic and intermittent basis. This involves moving materials by raising and lowering the load-handling device, then reversing the movement to return to the original position or a new location for the next cycle.

This article primarily discusses how to calibrate the span of an overhead crane using laser distance sensors.

Working Principle of Laser Distance Sensors

Phase-Shift Method: Reliable Technology for Medium to Short-Distance High-Precision Measurement

In this method, the source emits continuous modulated waves, and by calculating the phase difference between the emitted wave and the received wave, the distance can be accurately measured. The phase-shift method is often used for medium to short-range measurements, typically covering distances from several centimeters to several meters, with accuracy reaching millimeter levels, though the measurement time is relatively longer.

Phase-Shift Method: Ideal for medium to short-distance measurements, with a typical measurement range from several centimeters to several meters, and accuracy reaching millimeter levels. Due to the longer measurement time, it is commonly used in fields requiring high-precision measurements, such as industrial inspection and construction. (Learn more about how laser distance sensors work, click here.)

Span Measurement of Overhead Cranes Based on DADISICK Laser Distance Sensors

✅ Phase-Based Distance Measurement: Utilizes advanced phase-based distance measurement technology to ensure that the measurement process is both fast and precise, suitable for a variety of scenarios requiring high accuracy.

✅ Precision Optical System: Equipped with high-precision optical components, it maintains excellent measurement stability and accuracy even in outdoor or harsh environments (such as strong light, dust, vibration, etc.).

✅ Multiple Range Options: Offers five different measurement ranges, with a maximum range of up to 100 meters, to meet diverse measurement needs. Absolute accuracy is within ±2 mm, ensuring the reliability of measurement results.

✅ Diverse Communication and Output Options: Supports RS232/RS485 communication interfaces for easy integration with various control systems; also provides multiple analog output options, including 0-5V, 0-10V, 4-20mA, and 0-20mA, to meet different user signal reception needs.

✅ Robust and Durable Design: Features a die-cast metal housing with a sturdy structure, achieving an IP67 protection rating, effectively resisting water, dust, and other external elements, ensuring stable operation in harsh environments.

✅ Intuitive User Interface: Equipped with buttons and a display screen, allowing users to easily set the instrument’s operating parameters, such as range selection and output mode, enhancing operational efficiency.

✅ Wide Operating Temperature Range: Supports an operating temperature range of -10°C to 50°C, accommodating the usage needs in various climate conditions.

✅ Powerful Networking Capability: Supports networking of multiple laser measurement sensors with a computer or other devices, with a maximum connection of up to 64 units, facilitating large-scale measurement system integration and management.

In the lifting system of a crane, ensuring synchronous precision between components is crucial for maintaining equipment stability, improving operational efficiency, and ensuring operational safety. Laser distance sensors, with their high precision, non-contact measurement, and strong environmental adaptability, are widely used for measuring key parameters of cranes. The following introduces how to use laser distance sensors to measure the crane span.

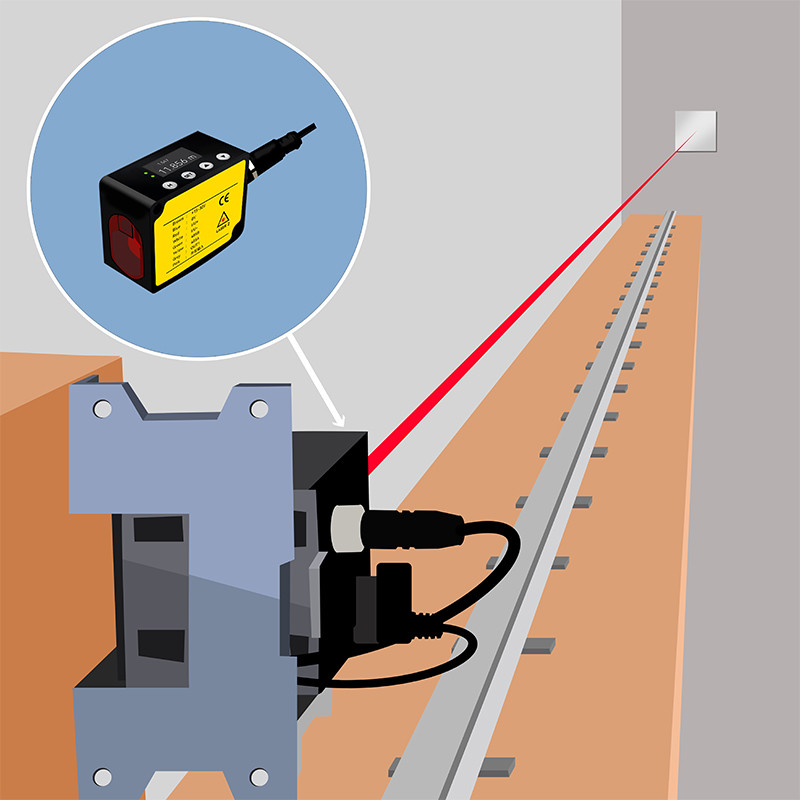

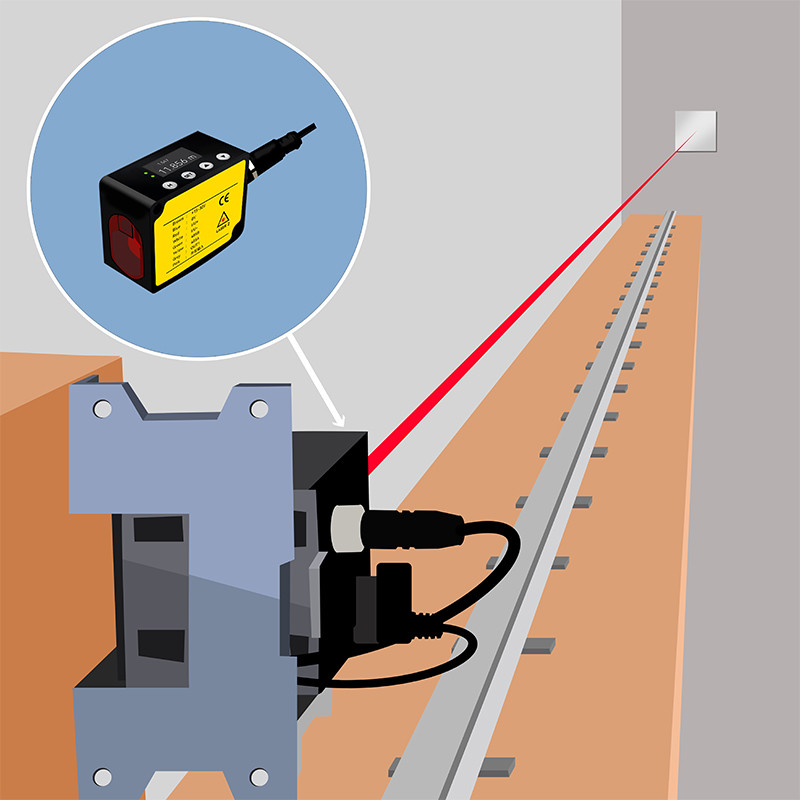

Measurement of Crane Span

The span of a crane typically refers to the horizontal distance between the two main beams (or supporting structures). When measuring the span using laser distance sensors, you can install two sensors at fixed positions on either end of the crane, ensuring they are aligned directly with each other’s target reflector or natural reflective surface (such as a wall). Once measurement is initiated, the laser beam is emitted from one sensor, received by the target at the other end, and reflected back. The distance between the two points, which is the crane's span, is determined by calculating the time taken for the light signal to travel back and forth. This method effectively eliminates the human errors associated with traditional measurement techniques, improving measurement accuracy.

Related Laser Distance Sensors & Laser Displacement Sensors

Measuring frequency: 1Hz-40Hz

Communication interface: RS232/RS485 (switchable)

Measuring distance: 0.2-100m

Measurement resolution: 1mm

Output method: PNP+analog+RS485

Resolution: 1mm

Laser type: red semiconductor laser Class II laser 655+10nm<1m

Reaction time: 50-200ms

Measure distance: 0.1-50m

Response time: up to 1.5ms

Output type: RS485

Measuring center distance: 400mm

Measuring range: ±200mm

Response time: up to 1.0ms

Repetitive accuracy: up to 2µm