How to Choose a Safety Mat? Comprehensive Guide to Selecting Industrial Safety Mat

- Share

- Issue Time

- Sep 18,2024

Summary

DADISICK comprehensive guide on choosing the right safety mat helps ensure optimal protection and efficiency across various sectors. Perfect for industries like automation, machinery, and electronics, our safety mats are designed to reduce accidents and safeguard employees. We offer services like sensor replacement and product line optimization. Our mats monitor equipment, halt hazards, and streamline production. Select the best safety mat with DADISICK's expertise in sensor technology.

1. Identify the work environment before selecting safety mats

First of all, it is necessary to clarify the industrial environment in which the safety mat, will be used, such as around mechanical equipment, at the entrance of the safety passage, at the bottom of the lifting platform, etc. Different environments have different requirements for the wear resistance, slip resistance, oil resistance, etc. of the safety mat.

2. Analyze safety mat switch functional requirements

Based on the application scenario, analyze the specific functional requirements of the safety switch mat. For example, is it necessary to have a step trigger function to control the start/stop of the equipment? Are special properties such as fire and corrosion resistance required? These requirements will directly affect the selection of the safety mat sensor.

3. Dangerous area coverage of pressure-sensitive safety mat

Determine the specific areas that need to be protected, such as the robot operation area, both sides of the conveyor belt, around the machine tool, etc. The shape and size of the industrial safety pressure mats should match the contours of these areas to ensure that the stop signal can be triggered in time when personnel enter the dangerous area.

4. Equipment collaboration

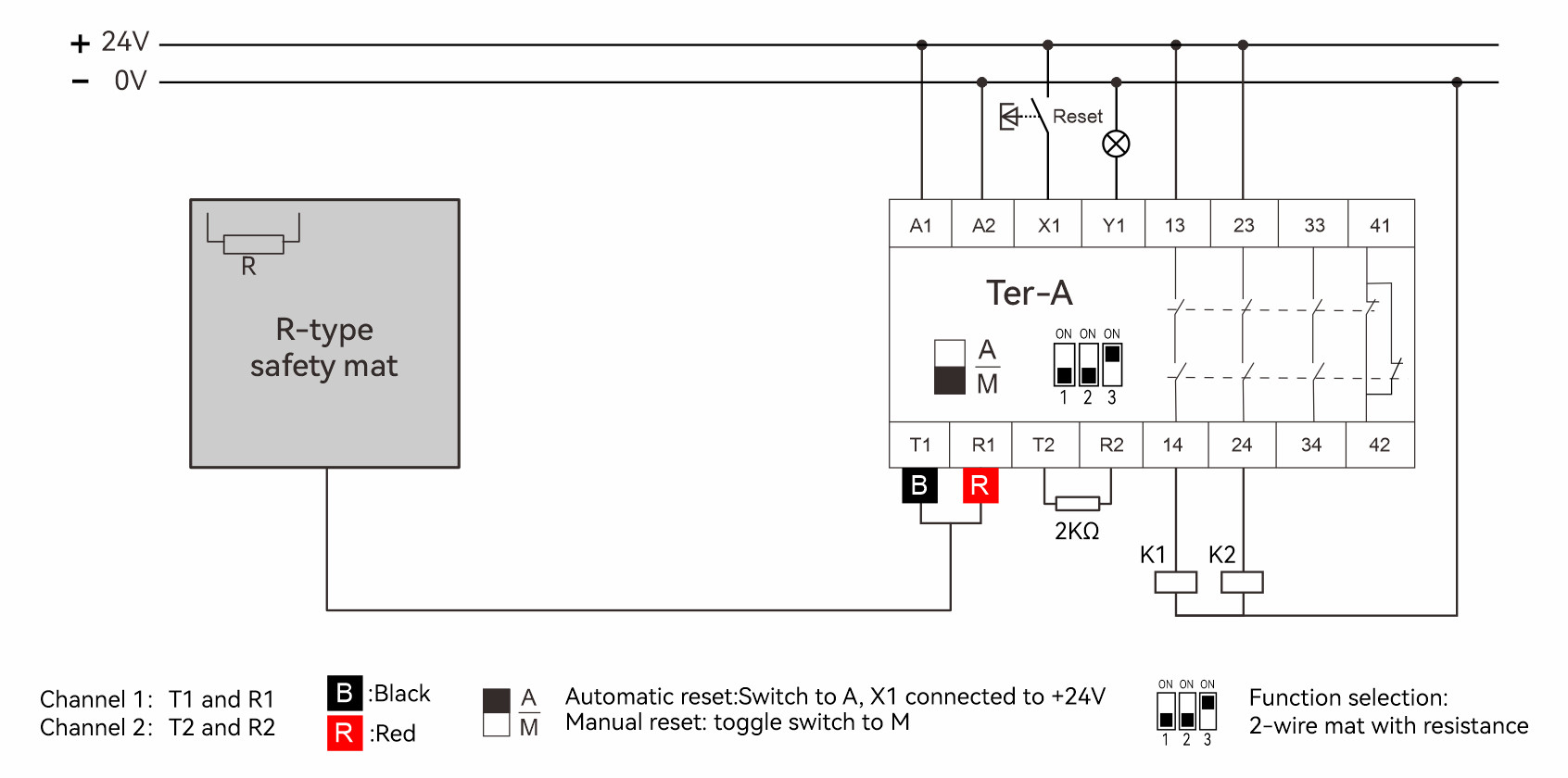

Consider the ability of the safety mat to work in conjunction with existing production equipment, such as compatibility with control systems such as safety relays and PLCs. Ensure that after the safety mat is triggered, it can quickly and accurately send a stop signal to the relevant equipment, and the equipment can respond in time.

1. Material Selection

The key is to select durable materials that meet safety requirements. Rubber materials are the first choice for industrial safety mat switches because of their good resistance to wear, compression and chemical corrosion. In particular, nitrile rubber, special load-bearing rubber EPM/EPDM materials and heavy-duty PVC plastics are waterproof, oil-resistant, resistant to high-temperature welding slag, have wheel rolling resistance and impact-resistant steel plate construction, which are suitable for most industrial environments.

2. Durability Evaluation

Evaluate the tensile and tear strength of the pressure-sensitive mat to ensure that it can withstand physical impact in the industrial environment without being easily damaged. At the same time, check that the edges of the pressure-sensitive safety mat are flat to avoid the risk of tripping due to edge distortion.

1. Trigger force and maximum allowable load

Pressure-sensitive safety mat have different trigger forces and maximum allowable load ranges, which need to be selected according to the weight of the person or object in the actual application scenario. For example, when detecting a person or heavy object weighing more than 20 kg, a safety carpet with a corresponding trigger force can be selected.

2. Mechanical life

This describes the durability of the safety mat sensor under normal use conditions. Generally speaking, safety switch mats with a mechanical life of more than 1 million times are more durable. Our DT15 series can reach a service life of 3,000,000 times.

3. Response time of Safety Switch Mats

The shorter the response time, the faster the stop signal can be triggered to ensure the safety of personnel and equipment. DADISICK's pressure-sensitive mats response time can reach 13ms

4. Protection level and environmental adaptability

Safety pressure mat sensors with a protection level of at least IP65 can prevent dust from entering and can withstand low-pressure jets of water, and are suitable for humid or dusty environments. At the same time, it is also necessary to consider whether its temperature and humidity adaptability range matches the industrial site environment.

1. Circuit Design of Safety Switch Mats

The circuit layout should be reasonable, avoid crossing or clutter, and ensure waterproof and dustproof design to prevent short circuit or failure. The inside of the safety mat should be full of switch sensing components, which must have high wear resistance and anti-interference performance to ensure timely and accurate response to pressure changes.

2. Insulation and Resistance

Ensure that the safety carpet does not pose a risk of electric shock to the human body when it is switched on. Check whether the resistivity and insulation of the safety mat sensor meet the safety mats industrial standards to prevent electric shock accidents caused by leakage.

3. Fire Resistance

For industrial environments where flammable substances may be present, safety mat switch must have good fire resistance. Choose pressure-sensitive mat with flame-retardant materials to reduce the risk of fire.

1. Brand Reputation

Choose a well-known brand and a reputable safety mat manufacturer to ensure the quality of the product and after-sales service. By checking brand rankings, customer reviews, and other information, you can better understand the performance and reputation of the product.

2. Quality Inspection Standards

Understand whether the manufacturer follows relevant international or domestic quality inspection standards, such as ISO, CE, etc. Ask the manufacturer to provide detailed test reports, including but not limited to pressure resistance test, waterproof test, corrosion resistance test, etc., to verify the safety performance of the product.

Detection method: pressure sensing method

Maximum allowable dynamic load: impact load<800kg/cm²

PVC anti slip surface layer: anti slip grade R9

Encapsulation and Surface Protection: PVC, CR

Response time: 13ms

Power consumption: <20kg

Maximum allowable dynamic load: impact load <800kg/cm²

Mechanical life: >3,000,000 times

1. Installation Requirements

Understand the installation requirements of the pressure-sensitive safety mat to ensure that it can be installed correctly and achieve the expected protective effect. Care should be taken during installation to avoid damage to the safety mat and the circuit system.

2. Maintenance

Perform regular maintenance on the safety carpet, check its wear, circuit connection status, etc., and replace damaged parts in time to ensure long-term stable operation and safety of the safety mat sensor.

Conclusion

In conclusion, the selection of suitable industrial safety mats requires a comprehensive consideration of actual application scenarios, material durability, safety performance, brand reputation and quality inspection standards. Through scientific and reasonable selection, installation and maintenance, the level of industrial electrical safety can be effectively improved, which can ensure the safe production of enterprises.

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.

Safety Edges is a technology that monitors the pressure distribution on the carpet through pressure sensing.