How to Select a Safety Light Curtain? Safety Light Curtain Purchase Considerations

- Share

- Issue Time

- Jun 6,2025

Summary

This article outlines how to select the security level of industrial light curtains based on risk assessment. It covers evaluating equipment type, application scenario, moving parts, operator behavior, and environmental factors. It advises choosing type 4 for high-risk equipment and type 2 for general risks. Also, it stresses the importance of environmental compatibility when selecting safety light curtain accessories.

Select Security Level of Industrial Light Curtains Based on Risk Assessment

International Standards

The safety classification of safety light curtains is mainly based on international standards (such as IEC 61496) and European standards (EN ISO 13849 - 1):

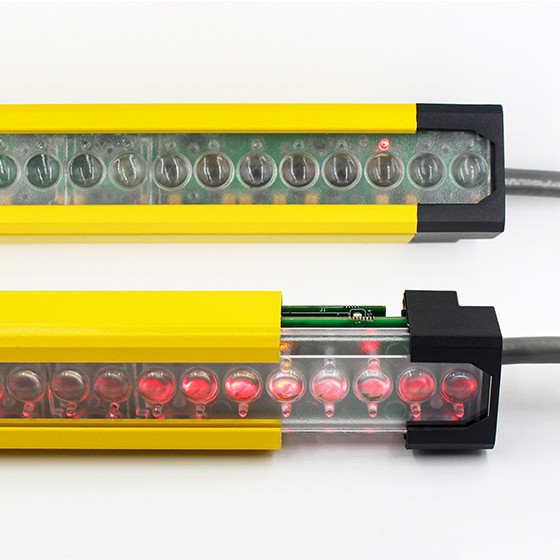

1. IEC 61496: Type 2 (corresponding to SIL1/PLc), fault detection during startup or restart, no redundant circuit is required, and the effective aperture angle (EAA) is generally 5°; Type 4 (corresponding to SIL3/PLe), using dual-loop redundant design, key components and circuits are equipped with backup, the effective aperture angle (EAA) is 2.5°, and has real-time self-check function.

2. EN ISO 13849-1: From Class B to Class 4, where Class 4 is the highest level of industrial light curtains, dual circuits with real-time self-checking function, redundant design to ensure that a single failure does not affect the safety function to accurately calculate the installation parameters.

Chinese Standards

The corresponding standards in China adopt to safety light curtain machine guarding are GB/T 19436 (Safety of machinery - Electro-sensitive protective equipment) and others.

GB/T 19436 standard stipulates that industrial safety light curtains must effectively detect the entry of human beings or objects in the detection area and trigger sensitive devices to disconnect the output signal equipment. Its mechanical structure must be strong enough, the electrical design must be reliable, and it must be able to resist electromagnetic and optical interference. The operating temperature range is generally -10℃~+55℃, and the protection level is at least IP65. The response time is usually no more than 18ms, and redundant design is required for high-risk scenarios. During installation, ensure that there are no blind spots in the dangerous area, and debugging must ensure that all performance standards are met. In addition, the safety light curtain should also pass relevant safety certifications.

Conduct a Risk Assessment on Your Equipment

Evaluate the equipment type and light curtain safety device application scenario

For example, punching machines, shearing machines and other equipment, due to their high-speed and high-precision operation characteristics, once an accident occurs, it often causes serious casualties, so these equipment usually need to use Class 4 safety curtain sensor. For some low-risk equipment such as conveyor belts, you can choose Class 2 guardshield safety light curtain.

Analyze the moving parts and operation methods of the equipment

Such as the moving speed and travel range of the moving parts such as the slide and tool of the equipment. The greater the kinetic energy and the faster the speed of the moving parts, the higher the potential danger, and the higher the safety level requirements for the laser safety light curtain.

Operator's behavior and range of activities

Consider whether the operator needs to frequently enter the hazardous area to operate, adjust or maintain the equipment during operation. If the operator needs to frequently enter the hazardous area, then it is necessary to select a light curtain with a higher safety level to ensure that the equipment can be detected and stopped in time when the operator mistakenly enters the hazardous area.

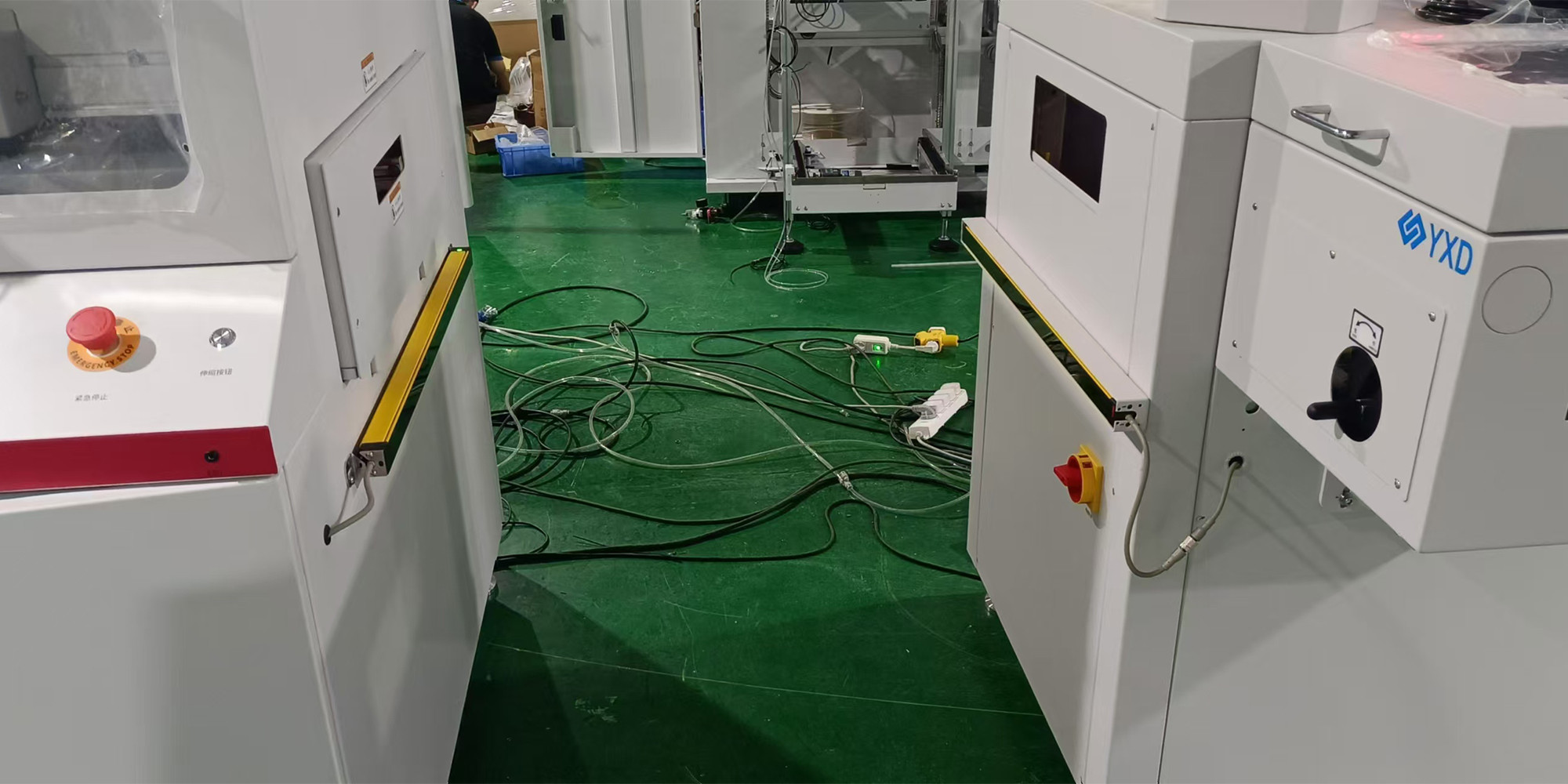

Consider working environment factors

For example, for equipment working in harsh environments such as high temperature, high humidity, and strong electromagnetic interference, it is necessary to select a light curtain safety system with corresponding protection level and anti-interference ability. At the same time, the impact of the environment on the performance of the machine safety light curtains should also be considered to determine whether the safety level needs to be improved.