Innovation in Stacker Level Detection: Ultrasonic Sensors Replacing Contact-Based Material Hammers

- Share

- publisher

- Zoe

- Issue Time

- Sep 19,2024

Summary

CSB30 series has a detection range of 350-6000 mm, with switching, analog, and RS485 output options. It can detect the height and position of materials inside the stacker in real-time, providing accurate control signals for the automatic distribution of materials. When the material height reaches the set value, the sensor sends a signal to the control system, which controls the stacker to perform corresponding actions, such as stopping the distribution or adjusting the direction of distribution.

Application of Ultrasonic Sensors in Stockpile Level Detection at a Stone Processing Plant

Background: One of our clients operates a stone processing plant. Their original contact-based detection system using long and short material hammers for the stacker’s level detection had broken down, and the dust resistance of the original design was poor. The client wanted to find a new solution that did not require changes to the original control requirements. They decided to replace the contact-based material hammer system with a non-contact ultrasonic sensor solution from DADISICK. After the upgrade, the new detection system performed well and operated stably.

Original Solution: Working Principle of the Contact-Based Detection System

The original system for material level detection on the stacker used a contact-based long and short material hammer detection device. The working principle was as follows: when the stacker was distributing material, if the long hammer made contact with the material, it would generate a switching signal and send it to the on-site PLC (Programmable Logic Controller). The PLC would then send a signal to the stacker indicating that the material height had reached the required level and the stacker should rotate 3° to continue stacking. If the material touched the short hammer, the system would immediately stop the upstream conveyor and the stacker, and issue an alarm.

New Solution: Working Principle and Selection of Ultrasonic Sensors

Ultrasonic sensors are designed based on the characteristics of ultrasonic waves, using piezoelectric chips as the core component. These sensors offer high accuracy, strong directionality, and perform well even in dusty environments. The sensor’s probe is equipped with temperature compensation components to ensure high measurement precision, even when the environmental temperature fluctuates.

The piezoelectric chip vibrates to emit ultrasonic waves when voltage is applied, and conversely, when ultrasonic waves return and act on the piezoelectric chip, they generate an electrical signal. By calculating the time taken for sound waves to travel between the sensor and the material, the system can accurately measure the material's height.

Sensor Selection:

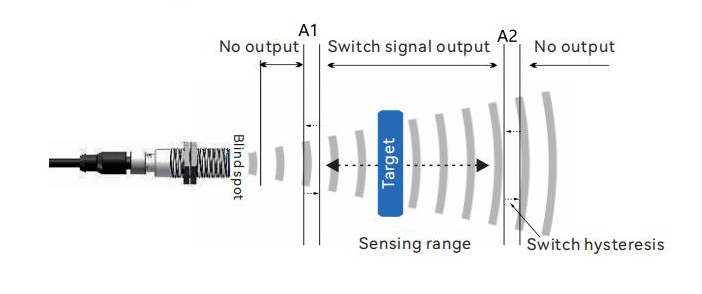

Based on the client’s requirements, DADISICK’s ultrasonic sensor model CSB30-6000 was selected. Its detection range of 350 mm to 6000 mm perfectly met the needs for level detection in the stone processing plant. Within this range, two detection points (A1 and A2) were set:

Switch Output, NO/NC SET

1️⃣ When the sensor detects point A1, it sends a switching signal to the PLC, which then controls the stacker to rotate 3° and continue stacking.

2️⃣When the sensor detects point A2, it outputs a signal to stop the upstream conveyor and the stacker, ensuring safe system operation.

NOTE: When setting the switching points A1 and A2, the built-in temperature compensation of the ultrasonic sensor should also be configured to ensure measurement accuracy.

DADISICK’s ultrasonic sensors provide not only high-precision measurements but also support multiple output modes, including proximity switch mode, window mode, reflector mode, dual-switch mode (hysteresis mode), analog output, digital output, and single/double sheet detection. These features make them suitable for various industrial applications. (For more information about the output modes of ultrasonic sensors, please click here.)

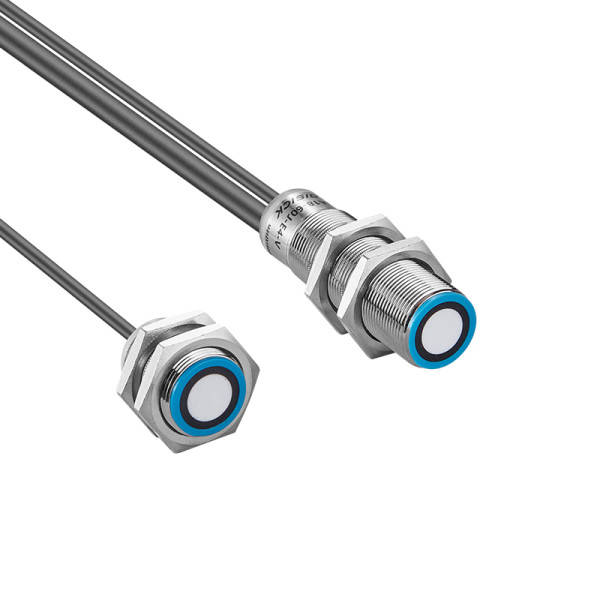

CSB30 Series Ultrasonic Sensors

|

Models

|

CSB30-2000 |

CSB30-4000

|

CSB30-6000

|

Detection range | 100 mm - 2000 mm | 200 mm - 4000 mm | 350 mm - 6000 mm |

|

Blind zone

|

0 mm - 100 mm |

0 mm - 200 mm

|

0 mm - 350 mm

|

|

Resolution

|

0.17 mm |

0.17-1.5 mm

|

0.17-2.5 mm

|

Response time | 82 ms | 162 ms | 232 ms |

Switching hysteresis | ±2 mm | ±4 mm | ±5 mm |

Switching frequency | 10 Hz | 5 Hz | 4 Hz |

Repeatability: ±0.15% of full-scale value | |||

Absolute accuracy: ±1 % (built-in temperature drift compensation) | |||

Input type: With synchronization and learning function | |||

Output type: Switch output; IO-Link output; Analog output; Digital output RS485 | |||

Material: Copper nickel plating , plastic fittings , glass filled epoxy resin | |||

Connection type: 5-pin M12 connector | |||

Protection Class: IP67 | |||

Ambient temperature: -25°C~+70°C (248~343K) | |||

Customer Video Feedback: Installation of Ultrasonic Sensors on Stacker

Advantages of Stacker Equipped with Ultrasonic Sensors

✅ Non-Contact Detection: Effectively avoids wear and dust interference issues caused by traditional contact-based detection methods.

✅ High-Precision Measurement: Ensures measurement accuracy and stability through temperature compensation and precise circuit design.

✅ Flexible Configuration: Multiple output modes meet the needs of different applications, allowing easy integration with existing PLC systems.

✅ Long-Term Benefits: Reduces maintenance costs, improves equipment reliability, and increases production efficiency.

Related Ultrasonic Sensors

Detection range: 20-120 mm

Detection range: 20-200 mm

Material: copper nickel plating

Connection type: 4-pin M12 connector

Detection range: 30-300 mm, 50-500 mm, 60-1000 mm

Material: copper nickel plating, plastic fittings

Connection type: 5-pin M12 connector

Detection range: 30-300 mm, 50-500 mm, 60-1000 mm

Material: copper nickel plating, plastic fittings

Connection type: 5-pin M12 connector

Detection range: 100-2000 mm, 200-4000 mm, 350-6000 mm

Material: copper nickel plating, plastic fittings

Connection type: 5-pin M12 connector

Detection range: 60-1000mm, 150-2500 mm

Material: copper sleeve nickel plated

Connection type: 5-pin M12 connector

Emitter - receiver spacing: 20-40 mm, 20-60 mm, 20-100 mm

Material: nickel plated copper, plastic fittings

Connection type: 2 m, PVP cable, 0.14 mm²

Groove depth: 68 mm

Slot width: 5 mm

Material: metal, aluminum

Connection type: 4-pin M8 connector

Detection range: 100-2000 mm

Material: plastic accessories, filled with epoxy resin

Connection type: 5-pin M12 connector

Output method: 1 NPN, NO/NC