Installation and Maintenance of Pressure-Sensitive Safety Mats for Industrial Safety

- Share

- Issue Time

- Sep 11,2024

Summary

This post covers installing and maintaining pressure - sensitive safety mats for industrial safety. It emphasizes proper installation and regular maintenance for optimal performance. The post discusses applications across various industries and gives installation procedures, maintenance tips, and common mistake avoidance. Follow the advice to ensure effective safety mats. Check the blog for more.

Safety carpet, also known as pressure-sensitive mat, safety mat, etc., is an important safety protection device that triggers the safety signal by sensing the personnel stepping on it, thus controlling the operation of the equipment and ensuring the safety of the operators.

It is important to understand the composition of the pressure sensitive mats before installing it. The main components of the industrial safety mat are as follows:

Rubber body: made of natural rubber, with good abrasion resistance and anti-slip properties.

Blank holder and right angle insert: used to fix the safety carpet and guide the signal line, different styles have their own specific installation methods and advantages.

Signal line: connects the pressure sensing mats to the controller and transmits the safety signal.

Controller (optional): optional controllers are available on request to implement more complex safety control logic.

Before installation, the following items must be confirmed:

Size match: ensure that the size of the safety mat switch matches the installation area to avoid being too large or too small, resulting in awkward installation or poor protection.

Components complete: verify that all components are complete, including the pressure sensing mats, blank holder, right angle insert, signal lines, and controller (optional).

Prepare environment: Clean the installation area and make sure the floor is level and free of debris so the carpet can be laid.

1. Laying the safety mat

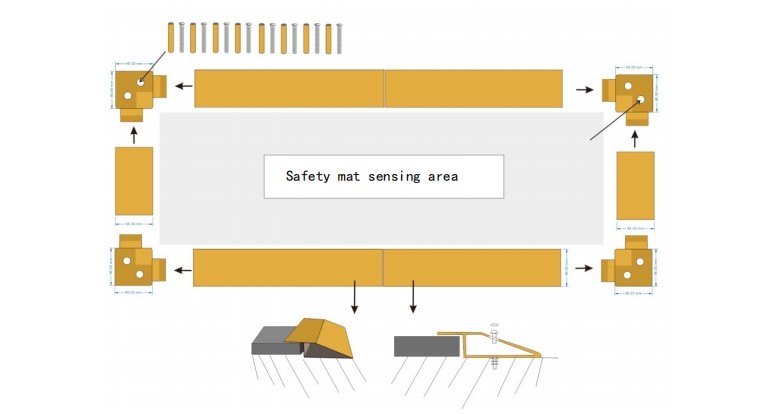

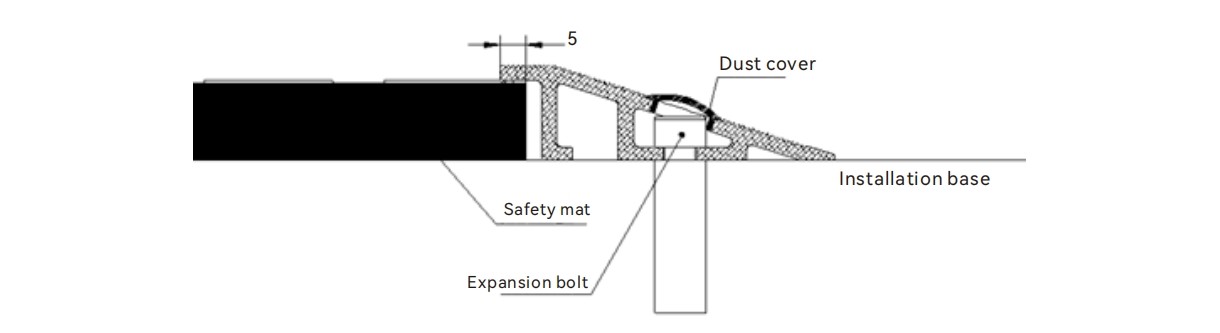

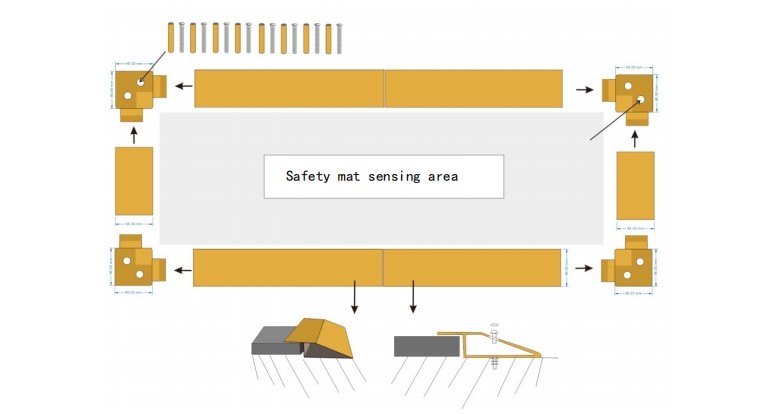

Lay the safety carpet flat in the intended location, making sure the edges of the safety mat sensor are aligned with the edges of the installation area. Pay attention to the orientation of the safety mat switch and make sure the signal cable outlets are in a position that allows easy access to the cables.

2. Blank holder and right-angle insert

Depending on the color and type of pressure-sensitive mat, DADISICK offers a wide range of presser edge and presser foot solutions, allowing customers to choose the appropriate style for different application scenarios. During installation, make sure that the blank holder and right-angle insert are firmly fixed to prevent the pressure-sensitive safety mat from shifting or buckling.

3. Lay the signal wire

Lay the signal wire from the exit of the safety mat and along the blank holder or fixed track to the controller position. Pay attention to the direction of the signal wire, should avoid bending and squeezing as much as possible, so as not to affect the quality of signal transmission. If necessary, the signal wire can be protected with a suitable wire trough or wire tube.

4. Wiring and Commissioning

According to the controller manual and the signal wire color of the safety carpet. After the wiring is completed, perform power-on debugging to ensure that the safety mat sensor can normally trigger the safety signal and control the operation of the equipment. During the debugging process, observe the status of the signal light and the response speed of the safety mat switch to ensure that everything is working properly.

During the installation process, be sure to follow the safety operation procedures to prevent electric shock or other safety accidents. After the installation is completed, regular cleaning and maintenance should be performed to check the wear of the pressure-sensitive mat and the connection status of the signal cable to ensure that the pressure-sensitive safety mat is always in good working condition. If the carpet is found to be damaged or the signal cable is broken, etc., it should be replaced or repaired in a timely manner so as not to affect the safety protection.

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.

Safety Edges is a technology that monitors the pressure distribution on the carpet through pressure sensing.