Laser Displacement Sensing for Metal Sheet Flatness Detection

- Share

- publisher

- Zoe

- Issue Time

- Sep 2,2024

Summary

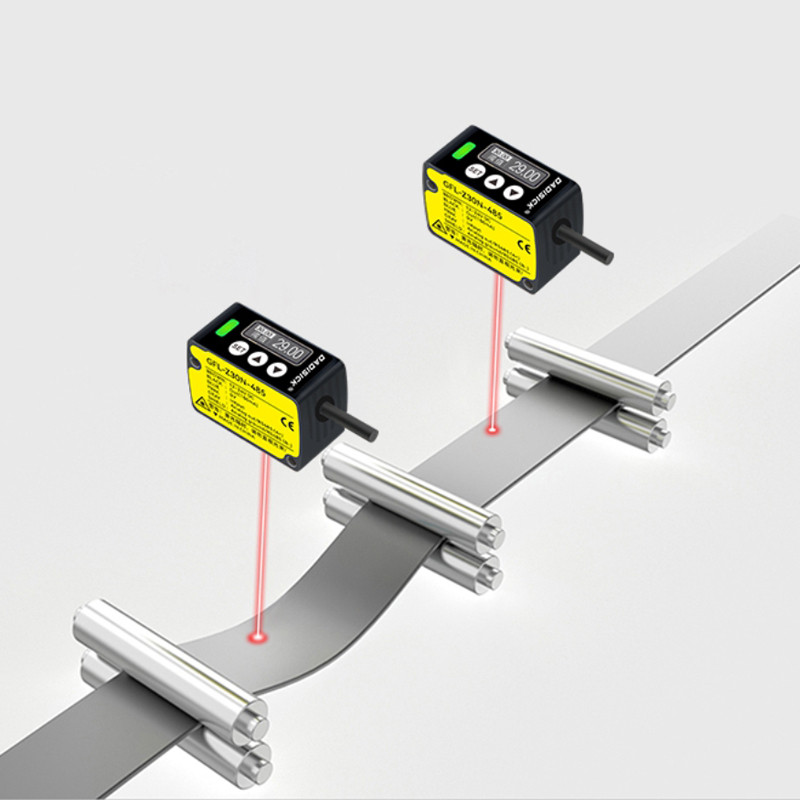

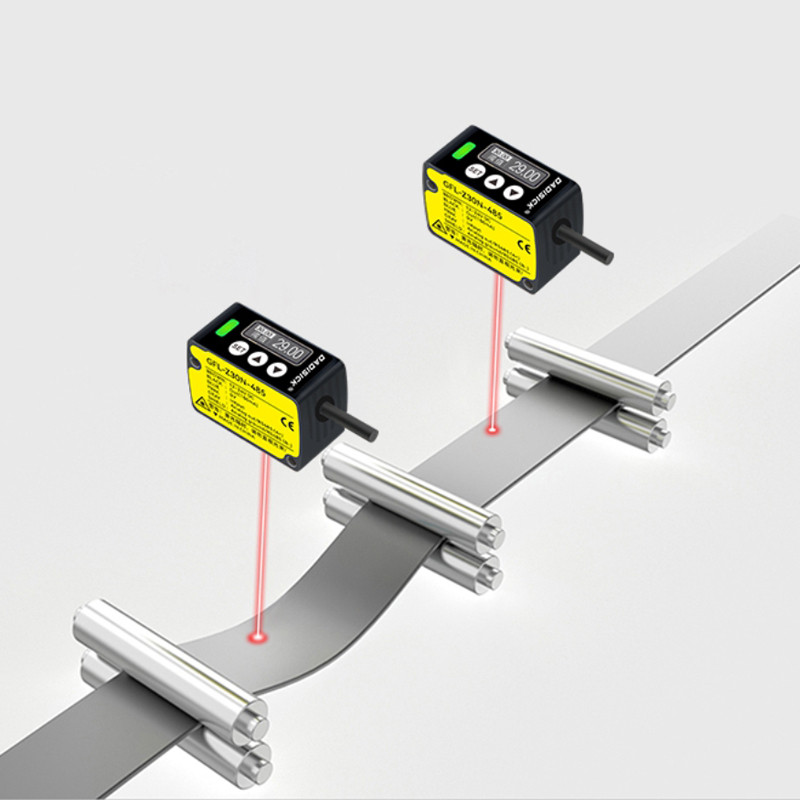

In the metal component manufacturing industry, there is a growing demand for improved flatness and straightness of sheet materials. A client specializing in hydraulic leveling equipment requires the leveling of metal sheets with a thickness of 0.2-2.5mm, followed by precise flatness and straightness detection. The recommended solution is the GFL-Z30N-RS485 laser displacement sensor.

Core Component for Metal Sheet Flatness Detection in Hydraulic Leveling Machines: Laser Displacement Sensors

Project Requirements

In the field of metal component manufacturing, there is an increasing demand for improved flatness and straightness of sheet materials. The client is a manufacturer specializing in the research and production of hydraulic leveling machine.

The specific project requirement involves leveling metal materials with a thickness of 0.2-2.5mm, followed by precise detection of the sheet's flatness and straightness to ensure that the final product meets high-quality standards.

Product Application

To meet these needs, we recommend the "GFL-Z30N-RS485" laser displacement sensor as the core component for flatness detection. This laser displacement sensor, with its exceptional performance and high precision, has become a critical part of hydraulic leveling machine.

Working Principle of GFL-Z30N-RS485 Laser Displacement Sensor

The GFL-Z series laser displacement sensor operates using the triangulation method. This principle involves emitting a laser beam that, upon hitting a target, reflects back to the receiver. The emission point, target, and receiving point form a triangle. By measuring the angles of this triangle, the distance between the sensor and the target can be calculated. Triangulation is typically used for very close-range measurements, with distances generally within tens of millimeters. The measurement accuracy can reach micron levels, and the measurement speed is extremely fast.

Flatness Detection Process

Leveling Operation:

The client’s hydraulic leveling machine performs the leveling operation on metal materials, ensuring that the surface flatness meets the required standards.

Laser Displacement Sensor Application:

The laser displacement sensor is installed on the leveling machine’s detection system to measure the flatness of the metal sheet. The sensor uses laser distance measurement technology to monitor even the slightest changes in the sheet surface in real time.

Data Analysis:

The data collected by the sensor is processed using advanced algorithms to generate detailed reports on flatness and straightness. These reports provide critical information for engineers to adjust the leveling machine parameters, ensuring the final product meets high-quality standards.

Product Overview: GFL-Z30N-RS485 Laser Displacement Sensor (Short-Range Series)

Product Features:

Repeatability: 10μm

Detection Distance: 25-35 mm

Protection Rating: IP60

Supported Outputs: Switching Output/Analog Output/RS485

Application Scenarios:

Laser displacement sensors are widely used in industries such as lithium batteries, printing and packaging, coating machines, and intelligent manufacturing. They are suitable for measuring physical quantities like length, height, width, distance, vibration, speed, orientation, presence of objects, shape, and flatness, as well as for applications such as flaw detection and atmospheric pollution monitoring.