Laser Displacement Sensors: The Ideal Tool for Inspecting the Status of Liner Inside Bottle Caps

- Share

- publisher

- Zoe

- Issue Time

- Sep 11,2024

Summary

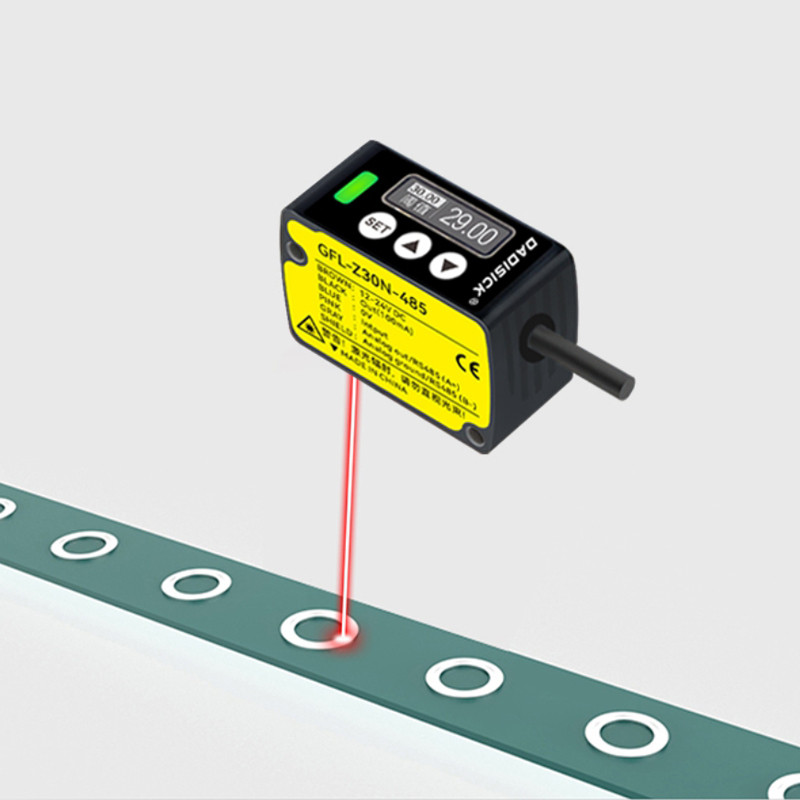

Laser displacement sensors demonstrate exceptional performance in detecting the status of liners inside bottle caps. By precisely measuring changes in depth or height at specific locations inside the cap, these sensors effectively identify the presence, absence, or number of liners, ensuring product quality and safety. This non-contact detection method not only enhances efficiency but also reduces the risk of misjudgments or missed detections.

Why Choose Laser Displacement Sensors for Inspecting Liners Inside Bottle Caps?

Liners inside bottle caps are used to provide a secure seal, commonly found in wine bottles, beverage bottles, and sauce containers. The liner prevents liquid leakage and also blocks external air or moisture from entering the bottle. It works by creating a tight seal between the cap and the bottle neck, utilizing the mechanical force of the cap's threads.

DADISICK Laser displacement sensors, with a high precision of up to 0.01mm, can accurately detect minute changes in depth or height within the cap, allowing for precise identification of whether a liner is present and properly placed. This level of accuracy reduces the risk of false positives or missed detections, which can occur with traditional methods that may involve physical contact, potentially damaging the cap or liner and slowing down production. The non-contact nature of laser displacement sensors eliminates these concerns, making them a reliable choice for such inspections.

✅ Measurement Range: 25 mm to 600 mm ✅ Repeatability: 10 μm / 30 μm / 70 μm / 200 μm / 400 μm ( 800μm) ✅ Linearity: ±0.1%F.S. (25 mm to 135 mm); ±0.2%F.S. (120 mm to 600 mm) ✅ Supported Interfaces: RS485 / Switch Output / Analog Current and Voltage

✅ Protection Rating: IP60 ✅ Operating Temperature: -10℃ ~ +40℃

✅ Cable: With 0.15 mm 5-Core Composite Cable 2m | |||

MODELS | Measurement Range Center Distance + Span | ||

|

NPN

|

NPN+Analog

|

NPN+RS485

|

|

|

—

|

GFL-Z30NM

|

GFL-Z30N-RS485

|

30 mm (±5 mm) |

|

GFL-Z50N

|

GFL-Z50NM

|

GFL-Z50N-RS485

|

50 mm (±15 mm) |

|

GFL-Z100N

|

GFL-Z100NM

|

GFL-Z100N-RS485

|

100 mm (±35 mm) |

GFL-Z200N | GFL-Z200NM | GFL-Z200N-RS485 | 200 mm (±80 mm) |

GFL-Z400N | GFL-Z400NM | GFL-Z400N-RS485 | 400 mm (±200 mm) |

Basic Working Principle of Laser Displacement Sensors for Inspecting Liners Inside Bottle Caps

Laser displacement sensors operate using triangulation, measuring the distance between the sensor and the target by analyzing the position of the reflected laser spot. The laser is focused and projected onto the object through an emission lens. When light reflected from an object hits the CMOS line, the position of the light spot changes with the distance to the object. A CMOS line enables precise measurement of objects at short distances. By calculating this positional change, the sensor determines variations in distance to the object.

For inspecting liners inside bottle caps, the sensor measures the depth or height at a specific point within the cap (usually where the liner should be). This allows for accurate detection of the liner’s presence and quantity.

Implementation Steps: How to Use Laser Displacement Sensors to Inspect the Status of Liners Inside Bottle Caps

Step 1: Calibration

Start by calibrating the laser displacement sensor to establish an accurate baseline reading in a clean, liner-free bottle cap.

Step 2: Set Threshold Values

Based on the thickness of the liner and the expected measurement tolerances, set appropriate distance thresholds. If the measurement exceeds these thresholds, it indicates the absence or overplacement of liners.

Step 3: Automated Inspection

Caps are automatically fed into the inspection area via a mechanical system (e.g., conveyor belt), where the laser displacement sensor scans and measures the designated spot inside the cap.

Step 4: Data Analysis

The control system receives real-time data from the sensor and compares it against the pre-set threshold values to assess liner placement.

Step 5: Feedback and Marking

For caps that do not meet the standards (either missing liners or multiple liners), the control system triggers an alarm or marking system for further handling.

Benefits of Using Laser Displacement Sensors for Inspecting Liners Inside Bottle Caps

✅ Non-contact Measurement: The entire process is contact-free, protecting the product and improving inspection speed without risking damage to the cap or liner.

✅ Real-time Monitoring: The system provides real-time feedback, flagging defective caps immediately without disrupting the production line’s efficiency.

✅ High Accuracy: With high precision and reliability, laser displacement sensors ensure consistent product quality, reduce human error, and lower production costs, facilitating smart manufacturing.

Related Optical Measurement Sensors

Response time: up to 1.0ms

Repetitive accuracy: up to 2µm

Response time: up to 1.5ms

Repetitive accuracy: up to 10µm

Output method: NPN/PNP+analog+RS485

Resolution: 1mm

Laser type: red semiconductor laser Class II laser 655+10nm<1m

Reaction time: 50-200ms

Measure distance: 0.1-50m

Measuring frequency: 1Hz-40Hz

Communication interface: RS232/RS485 (switchable)

Measuring distance: 0.2-100m

Measurement resolution: 1mm