Precision Positioning: DS Series Long-Range Laser Distance Sensor in ASRS Stacker Crane Applications

- Share

- publisher

- Zoe

- Issue Time

- Dec 21,2024

Summary

The DS series long-range laser distance sensor delivers precise and reliable positioning for ASRS stacker cranes. Its extended measuring range, high precision, and robust communication capabilities make it an ideal choice for optimizing ASRS efficiency and reliability. By addressing the core challenges of modern warehouse systems, DADISICK's DS series ensures seamless integration into automated workflows, contributing to safer, faster, and more accurate operations.

Precision Positioning: DS Series Long-Range Laser Distance Sensor in ASRS Stacker Crane Applications

Modern Automated Storage and Retrieval Systems (ASRS) rely on precise positioning and efficient operations. In ASRS stacker crane applications, accurate distance measurement and positioning are essential not only for ensuring operational efficiency but also for maintaining the accuracy and safety of goods handling. The DS series long-range laser distance sensor by DADISICK offers a reliable, high-performance solution tailored for these requirements.

Application Background

In ASRS systems, stacker cranes are tasked with retrieving and storing goods at high speeds and over extensive working ranges. This necessitates sensors with the following capabilities:

1️⃣ Long-range measuring capability to cover the entire rack system.

2️⃣ High precision and fast response to support real-time positioning during rapid crane movements.

3️⃣ Secure and reliable data transmission to integrate seamlessly into modern industrial networks.

DS Series Laser Distance Sensor Solutions

Features

▪️The DS series laser distance sensors are designed to meet the specific needs of ASRS systems.

▪️With a measuring range of up to 200 meters (available in 80m, 120m, and 200m variants), the sensors can accommodate ASRS systems of various sizes.

▪️Measurement precision of ±2mm ensures highly accurate positioning, even at long distances, meeting the stringent requirements of stacker crane operations.

▪️Supporting a measurement frequency of up to 1000 Hz, the DS series can quickly and accurately capture the position of fast-moving stacker cranes.

The non-contact design minimizes wear and maintenance, ensuring long-term reliability and efficiency.

▪️Equipped with SSL encryption protocol, the sensors ensure secure data communication, protecting against unauthorized access or data tampering. This is critical for safeguarding modern smart warehouses.

▪️Adopting the Ethernet 100BASE-TX communication standard allows for data transmission speeds of up to 100 Mbps, ensuring real-time feedback to control systems.

▪️The integrated LED display provides real-time sensor status and measurement data, enabling quick setup and parameter adjustments, which reduce installation and commissioning time.

Solution Implementation Steps

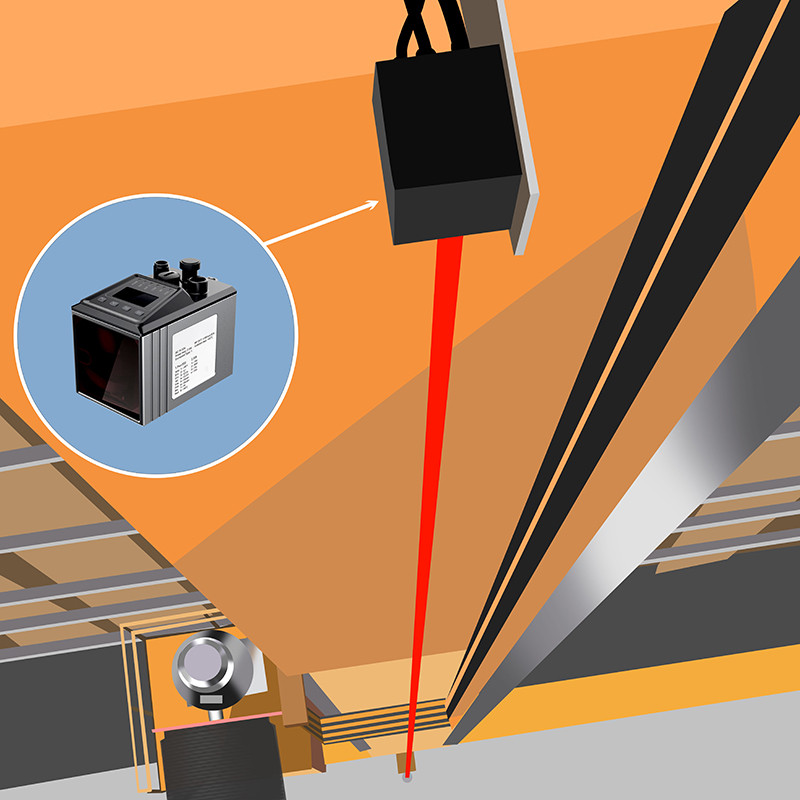

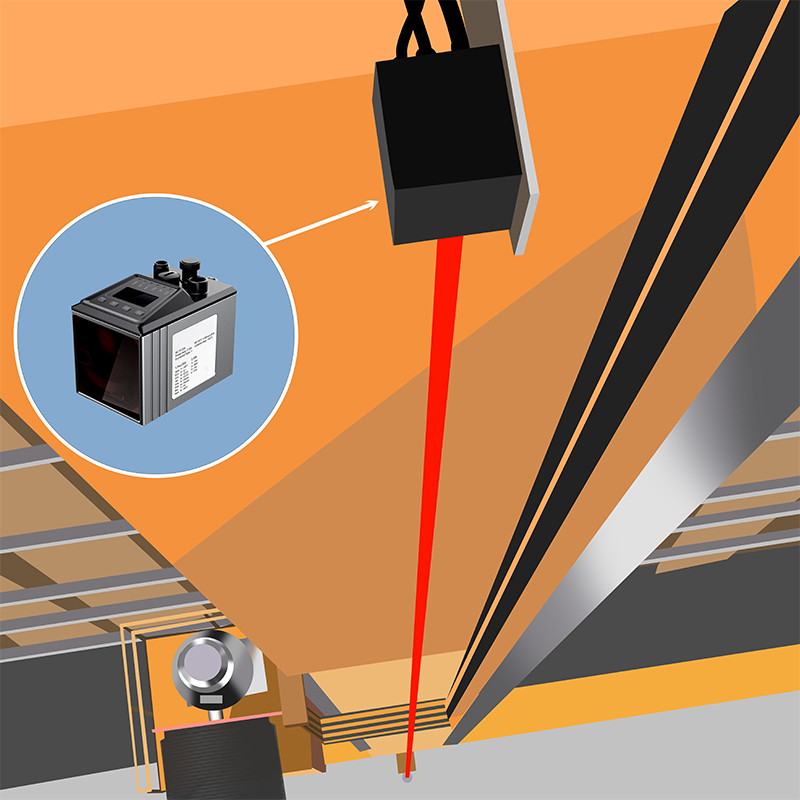

(1) Sensor Installation

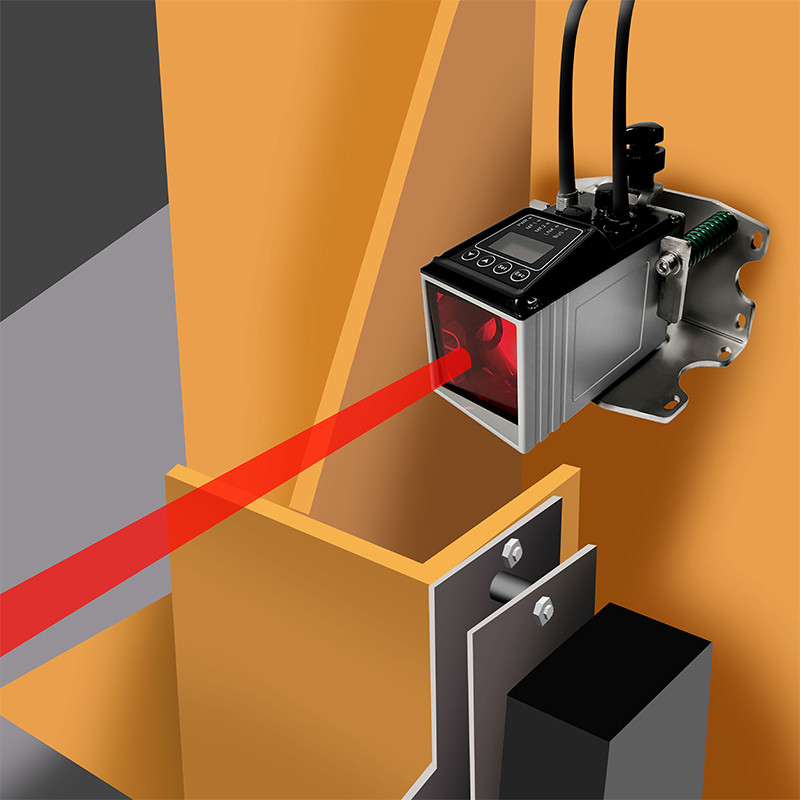

▪️Determine Installation Position: Based on the stacker crane’s structure, install the sensor on the top or side to ensure an unobstructed measurement of the target.

▪️Secure Mounting: Use brackets to securely mount the sensor and adjust the laser alignment to the target area.

▪️Connect Cables: Properly connect the power and Ethernet cables to ensure stable connections and avoid issues affecting sensor operation.

(2) System Integration and Commissioning

▪️Integration Configuration: Integrate the sensor into the control system and configure communication parameters to enable proper data transmission.

▪️Testing and Verification: Run the stacker crane to check if the sensor measures distances correctly and transmits data accurately, verifying stability via the system interface.

▪️Parameter Optimization: Fine-tune sensor settings (e.g., measurement range and frequency) and adjust the control system algorithms to optimize performance for precise crane positioning.

Possible Solutions

Measuring frequency: 1000Hz

Data transmission interface: SSl, Ethernet 100 BASE-TX

Measuring distance: 200m

Measurement accuracy: ±2 mm

Eective transmission distance: 200 m

Communication rate: 100 Mbit/s

Communication light divergence angle: 1°

Communication light receiving angle: 1.5°

Output method: PNP+analog+RS485

Resolution: 1mm

Laser type: red semiconductor laser Class II laser 655+10nm<1m

Reaction time: 50-200ms

Measure distance: 0.1-50m

Measuring frequency: 1Hz-40Hz

Communication interface: RS232/RS485 (switchable)

Measuring distance: 0.2-100m

Measurement resolution: 1mm