Prevent Machine Guard Failures: Essential Maintenance Checklist for Safety Light Curtains

- Share

- Issue Time

- Jun 10,2025

Summary

Ensure Type 4 Safety Light Curtain Reliability: Step-by-step maintenance for beam alignment, EMI shielding, occlusion testing & ISO 13849 compliance on presses/injection molders. Prevent downtime with calibration protocols.

Safety light curtain, also known as laser safety curtains. This optical sensor is widely used in various mechanical equipment and automated production lines as an effective safety protection device. It can detect the entry of people or objects in time and quickly send a signal to stop the machine's operation, thereby avoiding accidents. However, to ensure that the safety light curtains can play their protective role in a long-term and stable manner, daily maintenance work is essential. This article will give you a detailed introduction to the daily maintenance methods and the importance of the safety light curtain sensor.

Clean the Surface of the Safety Light Curtain Regularly

Clean dust and debris: During the use of the safety light curtain, dust, oil, fiber and other debris are easily accumulated on its surface. These debris will affect the transmission effect of the light beam, resulting in signal weakening or false alarm. Therefore, it is necessary to regularly use a clean soft cloth or soft brush to gently wipe the surface of the transmitter and receiver of the light curtain to remove dust and dirt. Avoid using too wet cloth to prevent liquid from penetrating into the interior.

Avoid corrosive cleaning agents: During the cleaning process, it is strictly forbidden to use cleaning agents containing abrasive ingredients or corrosive ingredients to avoid scratching or damaging the curtain light sensor lens. It is recommended to use antistatic cleaning agents and special lens cloths for cleaning to keep the surface of the light curtain clean and transparent. In oily environments, the cleaning frequency needs to be increased. It is strictly forbidden for oil, stagnant water and corrosive liquids to contact the light curtain

Check the Data Line of the Safety Light Curtain

Check cables and plugs: Regularly check whether the power cord, signal cord, and other cables of the safety laser curtain are worn, broken or loose, and whether the plugs are in good contact. If there are any problems, they should be repaired or replaced in time to ensure the stability and reliability of signal transmission.

Prevent electromagnetic interference: Check whether there are electromagnetic interference sources in the equipment around the laser safety curtains, such as motors, transformers, etc. If electromagnetic interference is found, appropriate shielding measures should be taken, such as using a metal casing, adding shielding wires, etc., to reduce the impact of interference on the performance of the light safety curtain.

Calibrate Light Curtain Position

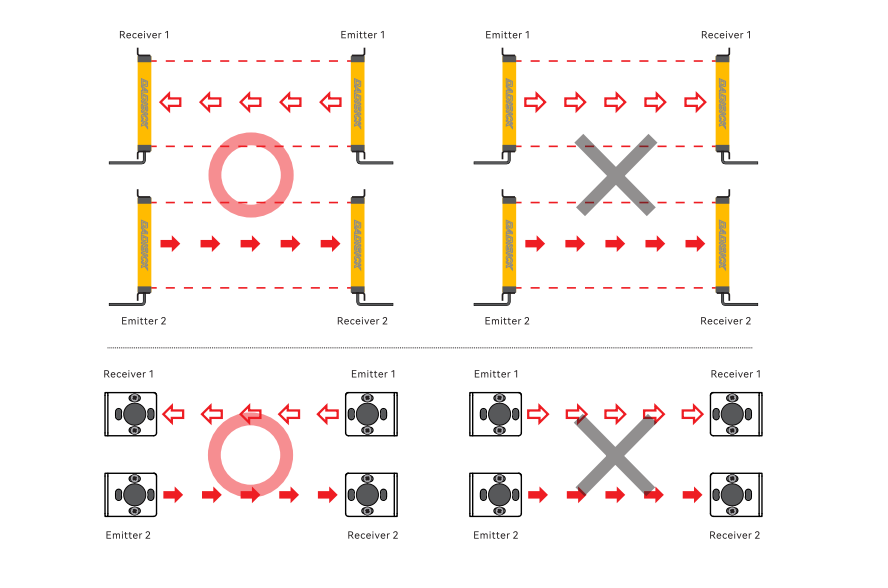

Ensure accurate beam alignment: The beam between the transmitter and receiver of the safety light curtains must be accurately aligned to ensure its normal operation. During maintenance, check whether the installation position of the laser curtains is offset or loose. If necessary, adjust and fix it in time to ensure the alignment accuracy of the light beam.

Check the mounting bracket: Check the firmness and stability of the mounting bracket. If it is loose or damaged, tighten or replace the bracket in time to prevent the safety laser curtain from position deviation or shaking due to bracket problems.

Functional Testing

Conduct an occlusion test: regularly block the light beam of the light curtain safety device with your hands or a special test tool to check whether it can detect and send a signal in time to stop the machine. At the same time, observe whether the indicator light of the light curtain is normal to ensure the reliability of its function.

Test response time: Use professional test equipment to detect the response time of the safety light curtain to ensure that it responds within the specified requirement. If the response time is too long, it may affect the safety performance of the equipment and require corresponding adjustments and repairs.

Detection range: 0.3-6m

Detection: fingers, hands

Security level: IP65

The QCE series safety light curtain is specifically designed for automated equipment and high-risk mechanical processing environments, providing excellent personal safety protection. Its unique branch indication function clearly displays the status of each beam, whether connected or interrupted, ensuring operators can immediately identify any potential safety risks. Additionally, this safety light curtain has strong anti-interference performance, maintaining stable and reliable operation even in the face of electromagnetic signals, flashing lights, welding arc light, or other environmental light sources. In challenging environments, it is the ideal choice for ensuring operational safety.

Ensure personnel safety

The main function of the safety light curtain is to protect the personal safety of operators. Through daily maintenance, problems with the light curtain sensor can be discovered and solved in a timely manner to ensure that it can work normally at critical moments and effectively prevent personnel from being mechanically injured. For example, if the laser curtain sensor installed on equipment such as punching machines and injection molding machines fails due to untimely maintenance, once the operator's hands or other parts of the body mistakenly enter the dangerous area, it may cause a serious accident.

Extend the service life of the equipment

Regular cleaning and maintenance of the safety light curtain can reduce the impact of dust and dirt on the internal components of the equipment, prevent damage to the components due to overheating, corrosion and other problems, and thus extend the service life of the light curtain. In addition, timely repair or replacement of worn parts can also help maintain the performance and stability of the equipment and reduce the failure rate of the equipment.

Improve production efficiency

Good maintenance can ensure the normal operation of the safety light curtain and reduce production interruptions caused by equipment failure. If the safety light barriers fail frequently, it will not only affect the production progress, but may also take a lot of time and cost to repair. Through daily maintenance, potential problems can be discovered in advance and solved in time, so that the equipment is always in the best working condition, thereby improving production efficiency and the economic benefits of the enterprise.

Comply with safety regulations and standards

Many countries and regions have formulated relevant safety regulations and standards, requiring enterprises to take effective safety measures to protect the safety of employees during the production process. As an important safety protection equipment, the maintenance and management of the safety light curtain pole must also comply with relevant regulations and standards. By regularly maintaining light safety curtains and keeping relevant maintenance records, enterprises can prove their efforts in safe production and avoid legal risks and fines due to non-compliance with regulatory requirements.

Beam spacing: 2.5mm

Number of optical axes: 32

Protection height: 77.5mm

Beam spacing: 30mm

Number of optical axes: 42

Protection height: 1230mm

Safety light curtain outputs (OSSD)2 PNP

Beam spacing:40mm

Number of optical axes:20

Protection height:760mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing:20mm

Number of optical axes: 10

Protection height: 180mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing: 80mm

Number of optical axes: 10

Protection height: 720mm

Safety Curtain outputs (OSSD):2 PNP