Safety Light Curtain Explained: Everything You Need to Know

- Share

- Issue Time

- Jun 3,2025

Summary

This article explores key parameters of safety light curtains, including resolution, safety level, detection height, and response time. It highlights the importance of selecting the right safety light curtain based on environmental adaptability and core certifications to ensure robust industrial safety.

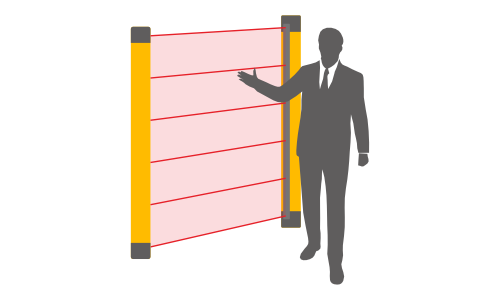

What Is a Safety Light Curtain?

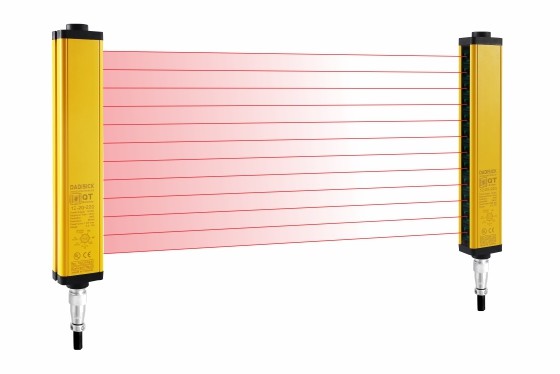

In modern industrial scenarios, such protection happens every moment. As the core equipment of industrial safety protection, the safety light curtain (also known as safety light curtain sensor or safety laser curtain) builds an invisible safety light barriers through the infrared beam array emitted by the transmitter and the real-time monitoring of the receiver. When the beam is blocked, its internal control system can trigger the equipment to shut down, effectively preventing mechanical injury accidents. As global safety standards become increasingly stringent, choosing a safety light curtain that complies with regulations and matches the scene has become an inevitable choice for industrial enterprises. This article will take you to a comprehensive analysis of the technical parameters the safety light curtain sensor to help you build a solid line of defense for safe production.

Resolution and Protection Type of Safety Light Curtains

Resolution (optical axis spacing) directly determines the minimum object size that the safety light curtain can detect, which is also the primary consideration for selection:

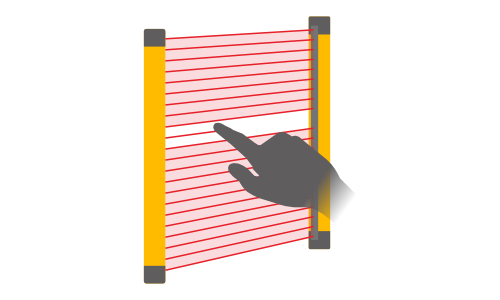

14mm Resolution

This resolution is specifically designed for finger protection, it is also know as finger safe light curtains. The narrow beam spacing of 14mm ensures that even the smallest fingers are detected. This is commonly used in precision stamping and injection molding machinery. Finger safe light curtains are ideal for applications where operators work very close to cutting or pressing zones. They are also suitable for precision assembly areas and small-part presses. EN ISO 13855 sets the biometric data for finger detection at 14mm, making it "finger safe".

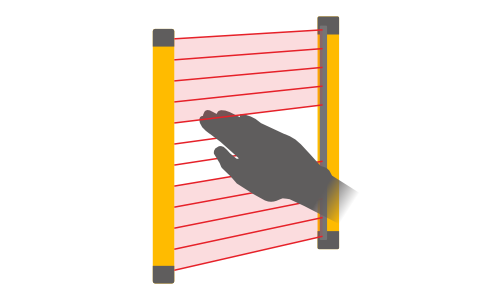

20mm Resolution

This resolution is used for palm protection. It can detect the entry of adult palms and is suitable for most machining areas where hand protection is required. They are often used in conveyor systems, pick-and-place robots, and general machine guarding where hands may reach into the hazard. This resolution provides a good balance of safety and flexibility for hand-level interaction. EN ISO 13855 sets the biometric data for hand detection at 30mm, but some light curtains with a 20mm resolution can also be used for hand protection in certain applications.

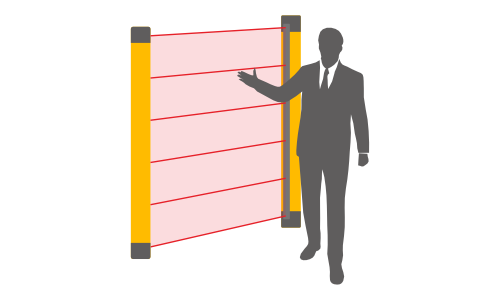

30-40mm Resolution

This resolution is designed for body protection. With a large protection range, it is suitable for logistics sorting, assembly lines, and other areas where full-body protection is needed. These light curtains can detect arms and larger objects. They are ideal for large equipment passages and can be used in applications where operators need to access machinery while still providing a high level of safety. EN ISO 13855 sets the biometric data for body detection at over 70mm, but light curtains with a 30-40mm resolution can also be used for body protection in certain cases.

≥50mm Resolution

This resolution is used for object detection or area protection. It is commonly seen at the entrance and exit of large equipment. These light curtains can detect larger objects and are suitable for applications where the goal is to prevent objects from entering a specific area. They are often used in perimeter guarding and access control systems. For example, they can be used to detect the presence of objects on conveyor belts or to prevent unauthorized access to certain areas. EN ISO 13855 sets the biometric data for body detection at over 70mm, making light curtains with a ≥50mm resolution suitable for this purpose.

Safety Level of Light Curtain Sensor Is the Lifeline

According to the international standard IEC 61496, safety light curtains are divided into several key levels, which are directly related to the reliability of protection and applicable scenarios. Among them, Category 4 safety laser curtain rely on dual processor architecture and real-time cross-detection technology. Even if a component fails suddenly, the protection function is still effective. It is suitable for high-risk stamping and shearing equipment and other scenarios:

| Safety Level | Technical Architecture | Safety performance | Applicable scenarios | Corresponding PL level | |

| Type B | Basic single circuit design | Only provides basic protection functions | Low risk simple application | PL b | |

| Type 2 | Single CPU + periodic self-test | The fault may be detected in the next cycle | Medium risk automation equipment | PL c | |

| Type 3 | Dual channel redundant design | High reliability, single failure does not affect the function | High risk machinery | PL d | |

| Type 4 | Dual CPU + real-time dual-loop self-checking | A failure in one of the channels does not affect the safety function | High-risk stamping/ shearing equipment | PL e | |

Detection Height and Protection Range of Laser Safety Curtains

The detection height refers to the vertical range of the effective coverage by light curtain pole of the laser curtains. The selection should follow the "full coverage principle" to ensure effective protection from the bottom light beam to the top light beam:

1.The distance between the bottom optical axis of the safety light curtain and the standing surface of the personnel should be ≤300mm to avoid the danger of entering from below;

2.The top optical axis must be above the upper edge of the protective area to ensure full area coverage;

3.Typical height specifications: 80mm (small tooling) → 480mm (standard protection) → 1560mm (full body high protection)

Taking a large press as an example, the protection height should meet the following requirements: slider stroke + adjustment margin + safety redundancy. For example, if the slider stroke of a 200T punch press is 300mm, the light curtain height must be at least 480mm.

Detection Distance and Response Time of Laser Curtain Sensor

The detection distance is the maximum effective distance between the transmitter and the receiver of light barriers, and the response time is the time difference between the occurrence of occlusion and the output signal. The response time of high-end products can be ≤15ms. These two parameters are directly related to the braking performance of the system:

Detection distance: refers to the maximum effective distance between the transmitter and the receiver, generally ranging from 0.3m to 10m.

Response time: refers to the time difference from when occlusion occurs to when the output signal is transmitted. High-end products can reach ≤15ms (such as DADISICK's QT series)

The safety distance must be calculated using the ISO 13855 formula: Safety distance (S) = human approach speed × response time + additional distance

For example, for a light curtain with a response time of 15ms, if the device takes 200ms to shut down, then S=2000mm/s×(0.2s+0.015s)+150mm≈580mm

Detection range: standard 0.3-6m, customizable 0.3-45m

Detection: fingers, Hands, Arm/body

Security level: IP65

This safety light curtain is designed for automated facilities and high-risk mechanical operation areas. Its key feature is maintaining a reliable connection within a 45-meter range, particularly suitable for complex operating environments. The robust casing ensures impact resistance, ensuring stable operation in various conditions. The product undergoes comprehensive testing to guarantee high performance and reliability.Output Signal Types of Safety Light Curtains

The output mode of the safety light curtain determines its integration solution with the equipment:

Relay output (passive contact):

1. Can directly control ≤5A load

2. Strong anti-interference, suitable for workshops with a complex electromagnetic environment

3. This output is standard for a punch press special device

Transistor output (NPN/PNP):

1. Extremely fast response speed (μs level)

2. Directly connected to the PLC control system

3. External relays are required to drive high-power equipment

Environmental Adaptability Parameters

Industrial environments are complex and diverse, and safety light curtains need to have strong environmental tolerance:

Protection level: at least IP65 (dustproof and waterproof), the food industry recommends IP69K (high-pressure washing resistance), for example, DADISICK's QRF series laser light curtain has good waterproof performance.

Temperature range: standard type (-10℃~+55℃), wide temperature type can reach -30℃~+70℃.

Anti-light interference: ambient light interference ≥100,000 Lux, avoid malfunction caused by direct sunlight.

Anti-vibration performance: special models for punching machines need to be equipped with multiple shock-absorbing pads, such as DADISICK's QS series light curtain sensors, which is specially developed for punching equipment and has good anti-vibration capabilities.

Compliance is a basic requirement for safety equipment, and the following certifications must be checked:

International certification: ISO 13849, IEC 62061

Domestic certification: GB/T 19436 (Mechanical safety - electro-sensitive protective equipment)

Special certification: explosion-proof certification (chemical industry), CE/UL certification (export equipment)

Related Hot Sale Safety Light Curtains

Beam spacing: 30mm

Number of optical axes: 42

Protection height: 1230mm

Safety light curtain outputs (OSSD)2 PNP

Beam spacing:40mm

Number of optical axes:20

Protection height:760mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing:40mm

Number of optical axes: 26

Protection height: 1000mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing: 10mm

Number of optical axes: 102

Protection height: 1010mm

Safety curtain outputs (OSSD): 2 PNP

Beam spacing: 80mm

Number of optical axes: 12

Protection height: 880mm

Safety Curtain outputs (OSSD):2 PNP