Safety Light Curtain Product Selection Guide

- Share

- publisher

- Vicky

- Issue Time

- Sep 28,2024

Summary

When purchasing a safety light curtain product, you need to consider multiple factors, including the degree of danger, the object to be protected, the working environment, key parameters, brand and model selection, and installation and maintenance. By carefully evaluating and comparing the features and performance of different products, you can choose the safety light curtain product that best suits your needs.

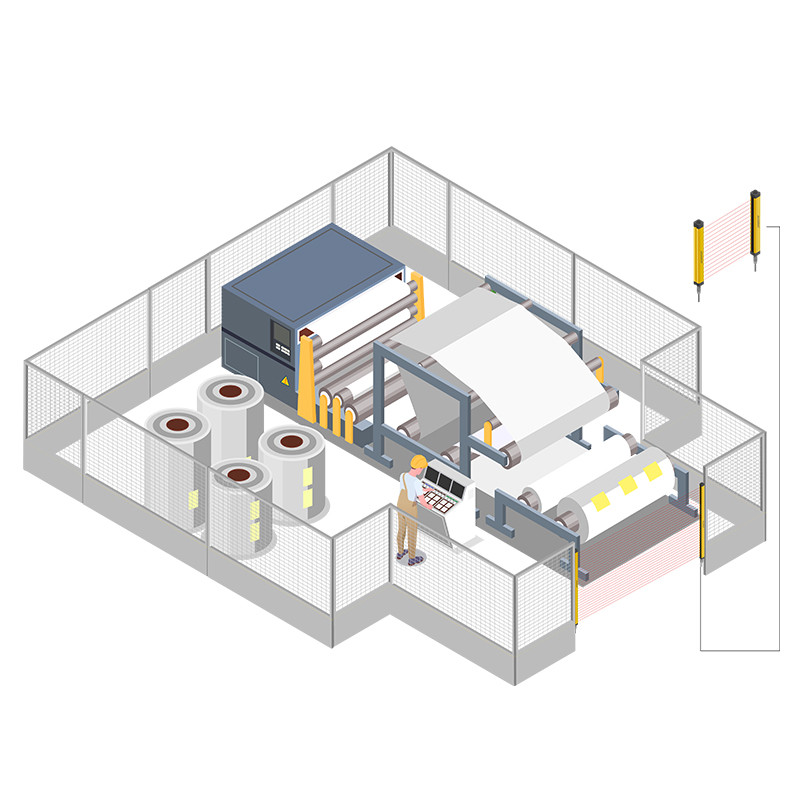

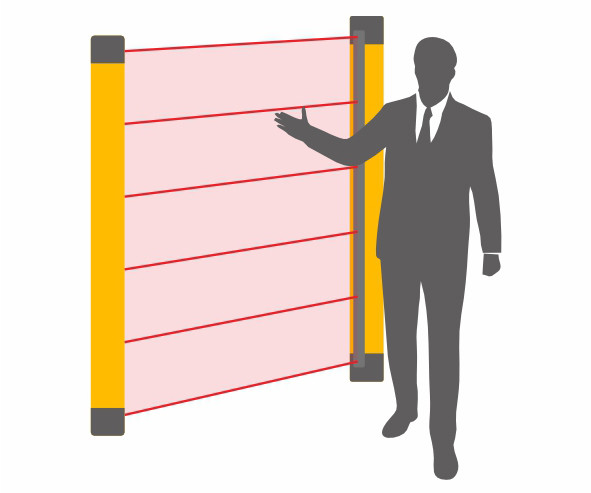

Safety light curtains, also known as photoelectric safety protection devices, are important devices used in modern factories to protect personnel from mechanical equipment. As an indispensable safety protection device in industrial automation, safety light curtains can effectively protect operators from harm caused by mechanical equipment. When purchasing safety light curtains, you need to consider a variety of factors to ensure that they perform best in specific application scenarios. The following is a guide to purchasing safety light curtain products to help you choose the right safety light curtain.

Clarify Requirements and Work Environment

Danger level assessment

Assess the degree of danger caused by the equipment to people, and select the appropriate safety level according to the degree of danger. The safety level of safety light curtains is usually divided into type 2 and type 4. Type 4 safety light curtains have a higher safety protection level than type 2 and are suitable for high-risk occasions, such as punching machines and welding equipment. Type 2 safety light curtains are suitable for low-risk occasions, such as assembly lines. Select the appropriate safety light curtain according to the required risk protection level.

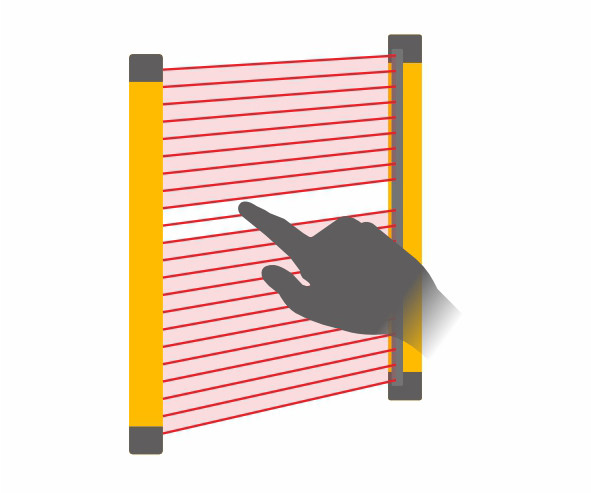

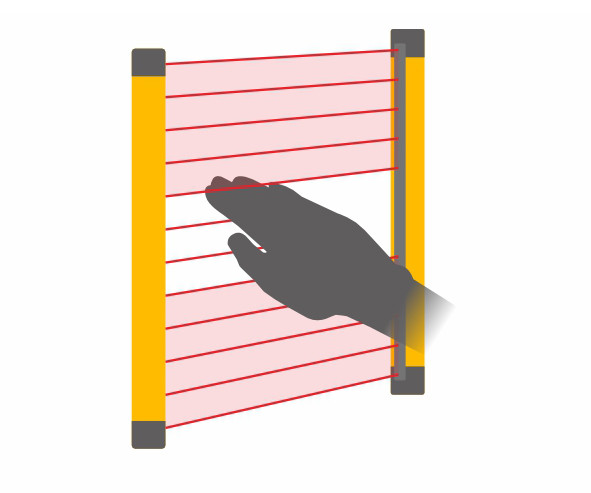

Object of protection

Determine whether the object to be protected is a finger, palm, arm or the entire human body, which will affect the selection of optical axis spacing.

Working environment

Consider factors such as vibration, dust, light interference, temperature, humidity and other factors in the working environment, and select the type of safety light curtain that can adapt to these environmental requirements. The use environment is also an important factor to consider when selecting a safety light curtain. If the light curtain needs to work in harsh environments such as high temperature, humidity, and dust, it is necessary to select a light curtain with a good protection level (such as IP65, IP67). In addition, it is also necessary to consider whether the light curtain has anti-interference ability to cope with the influence of external light and electromagnetic interference.

Key Parameter Selection

Optical axis spacing

The optical axis spacing refers to the distance between two adjacent light spots in the safety light curtain. Smaller optical axis spacing can provide higher protection accuracy, but may increase costs. Resolution refers to the fineness of the light curtain detection, usually expressed as the distance between the light beams. Higher resolution can detect smaller objects or details, suitable for occasions that require precise detection. For example, a light curtain with a resolution of 14mm can detect fingers, while a light curtain with a resolution of 30mm is more suitable for detecting arms. When choosing a light curtain, you need to choose the appropriate resolution according to the part that needs to be protected.

Protection height and length

The protection height should exceed the operating height by a certain distance to ensure the safety of the operator. The protection length should be determined according to the actual situation of the machine and equipment to cover the entire danger zone.

The beam distance

The beam distance refers to the straight-line distance between the safety light curtain transmitter and the receiver. The conventional safety light curtain beam distance is 0 to 3 meters, but some models can reach a longer distance.

Detection range

The detection range of a safety light curtain determines the size of the area it can cover. It is necessary to select a light curtain with a sufficiently long detection distance based on the size of the equipment in the actual use scenario or the coverage of the hazardous area. Generally speaking, the detection distance of a light curtain can range from tens of centimeters to tens of meters.

Reaction time

The reaction time of the safety light curtain determines how quickly it can react. When selecting, make sure that the reaction speed of the light curtain matches the operating speed of the equipment, especially on high-speed mechanical equipment, where a faster reaction time can reduce safety hazards.

Signal output method

There are many signal output methods for safety light curtains, such as relay output, NPN output, PNP output, etc. When selecting, make sure that it matches the control system and interface requirements of the machine equipment.

Brand and Model Selection

As a safety protection device, the quality and reliability of the safety light curtain are of vital importance. When choosing a product, you should give priority to brands with a good reputation, reliable technology and perfect after-sales service. This will not only ensure the long-term stable operation of the equipment, but also provide timely technical support when problems arise. According to the results of the above analysis, select the appropriate model. Different models of safety light curtains may differ in function and performance, and need to be selected according to actual needs.

Installation and Maintenance

Installation method

Choose a suitable installation method according to the actual situation on site, such as L-shaped groove side installation, pipe bracket side installation, etc.

Cable length

After determining the shooting distance, you also need to consider the length of the cable to ensure that the safety light curtain can work properly.

Maintenance and inspection

Regularly check the fixing of the safety light curtain, the status of the transmitter and receiver, and the connection of the cable.

Perform maintenance and maintenance according to the manufacturer's recommendations to ensure the long-term stable operation of the safety light curtain

In short, when purchasing safety light curtain products, you need to consider multiple factors such as the degree of danger, the object to be protected, the working environment, key parameters, brand and model selection, installation and maintenance, etc. By carefully evaluating and comparing the characteristics and performance of different products, you can choose the safety light curtain product that best suits your needs. At the same time, it is recommended to consult the equipment supplier or professionals to ensure a smooth purchase process.

DADISICK's Hot Selling Safety Light Curtains

Beam spacing:20mm

Number of optical axes: 40

Protection height: 780mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing: 10mm

Number of optical axes: 102

Protection height: 1010mm

Safety curtain outputs (OSSD): 2 PNP

Beam spacing:40mm

Number of optical axes: 20

Protection height: 760mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing:40mm

Number of optical axes: 54

Protection height: 2120mm

Safety Curtain outputs (OSSD):2 PNP