Safety Light Curtain: The Guardian of Modern Industrial Safety

- Share

- publisher

- Vicky

- Issue Time

- Aug 24,2024

Summary

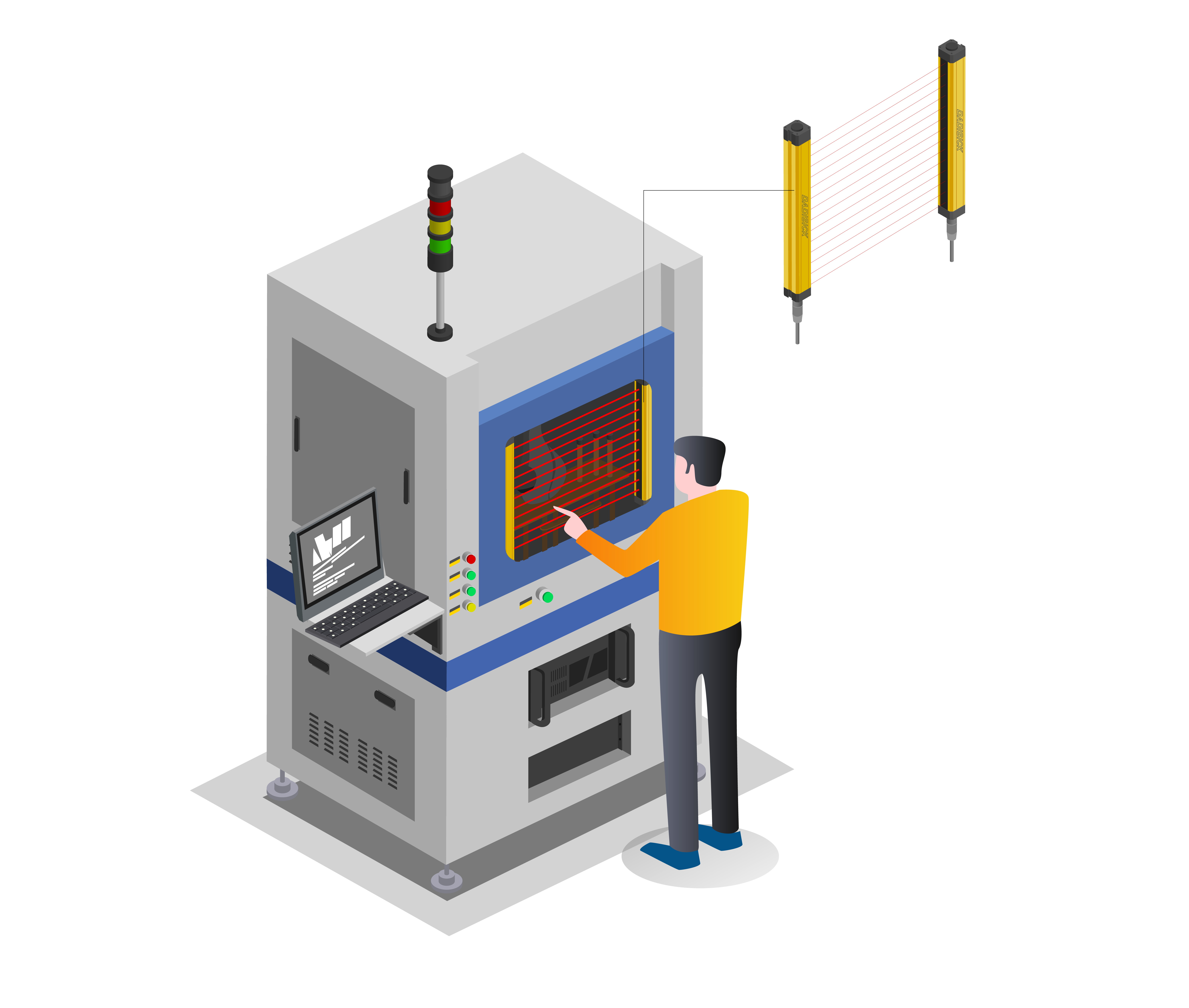

Safety light curtains are devices that use infrared to detect and protect dangerous areas. They are widely used in the field of industrial automation. The invisible protection network formed by the transmitter and receiver can quickly respond to abnormalities and trigger safety measures to prevent people from mistakenly entering dangerous areas.

In the modern industrial field, with the widespread application of automation equipment, the collaborative work between people and machines has become more and more frequent. However, this efficient production method also brings potential safety risks. In order to ensure the safety of workers, safety light curtains have emerged as an efficient and reliable safety protection device. This article will give you an in-depth understanding of the working principle, application field and importance of safety light curtains.

Introduction of Safety Light Curtain

Safety light curtain, also known as photoelectric safety protection device, safety protector, punch protector or infrared safety protection device, is a safety device that uses infrared beams to detect and protect dangerous areas. It originated from the German automation equipment production line and has been widely used around the world, especially in China's mechanical processing, production and other fields, playing an irreplaceable role.

Safety Light Curtain Working Principle

The working principle of the safety light curtain is based on the photoelectric effect. Its core components include a transmitter and a receiver, which form an invisible protective net through infrared beams. The transmitter continuously emits modulated infrared light, which is received by the receiver. When an object (such as a human body or a mechanical part) enters the safety light curtain area, it will block part or all of the infrared beam, causing the safety light signal received by the receiver to change. At this time, the internal circuit will respond quickly and output a signal to the control system, triggering safety measures such as emergency braking, shutdown or alarm, thereby avoiding safety accidents.

Main Components of Safety Light Curtains

Transmitter

Responsible for emitting modulated infrared light.Receiver

Receives infrared light from the transmitter and monitors changes in the optical signal.

Signal processing device

Processes the signal from the receiver, determines whether an object has entered the dangerous area, and triggers corresponding safety measures.

Optical system

Includes light source, lens group, reflector and color filter, etc., used to optimize the emission and reception of infrared beams.

Bracket

Supports the frame part of the entire device to ensure the stability and accuracy of the safety light curtain.

Application Areas of Safety Light Curtains in Industrial Automation

Mechanical processing equipment

Such as stamping machinery, shearing equipment, metal cutting equipment, etc. These equipment are prone to cause personal injury during operation. Safety light curtains can effectively prevent people from entering dangerous areas by mistake.

Automated production lines

In automated assembly lines, automated welding lines and other occasions, safety light curtains can monitor and protect the safety of workers in real time.

Logistics transportation system

In logistics links such as warehousing and packaging, safety light curtains can be used to monitor the flow of goods and prevent collisions between people and transportation equipment.

Public transportation

In equipment such as elevators, escalators and automatic doors, safety light curtains can ensure the safety and convenience of passengers.

Advantages and Features of Safety Light Curtains

Efficient and reliable

The safety light curtain can respond quickly and trigger safety measures to effectively prevent safety accidents.

Contactless protection

It avoids the operational inconvenience and safety hazards that may be caused by traditional physical protection equipment.

Strong adaptability

It can be customized according to different industrial scenarios and needs, such as ultra-thin safety light curtains suitable for occasions with limited space.

Easy to install and maintain

Compared with traditional mechanical protection equipment, the installation and adjustment process of safety light curtains is simpler.

DADISICK's Hot Selling Safety Light Curtains

Beam spacing: 80mm

Number of optical axes: 46

Protection height: 3600mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing:40mm

Number of optical axes: 42

Protection height: 1640mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing: 40mm

Number of optical axes: 32

Protection height: 1240mm

Safety sensors for machines outputs (OSSD)2 PNP

Beam spacing: 10mm

Number of optical axes: 164

Protection height: 1630mm