Safety Light Curtains are Used for All-Around Protection in Industrial Automation Production Lines

- Share

- publisher

- Vicky

- Issue Time

- Aug 21,2024

Summary

Safety light curtains are widely used and crucial in industrial automation production lines. As an advanced safety protection device, it protects workers and equipment through an invisible barrier composed of infrared beams, preventing accidental injuries that may occur during the automation process.

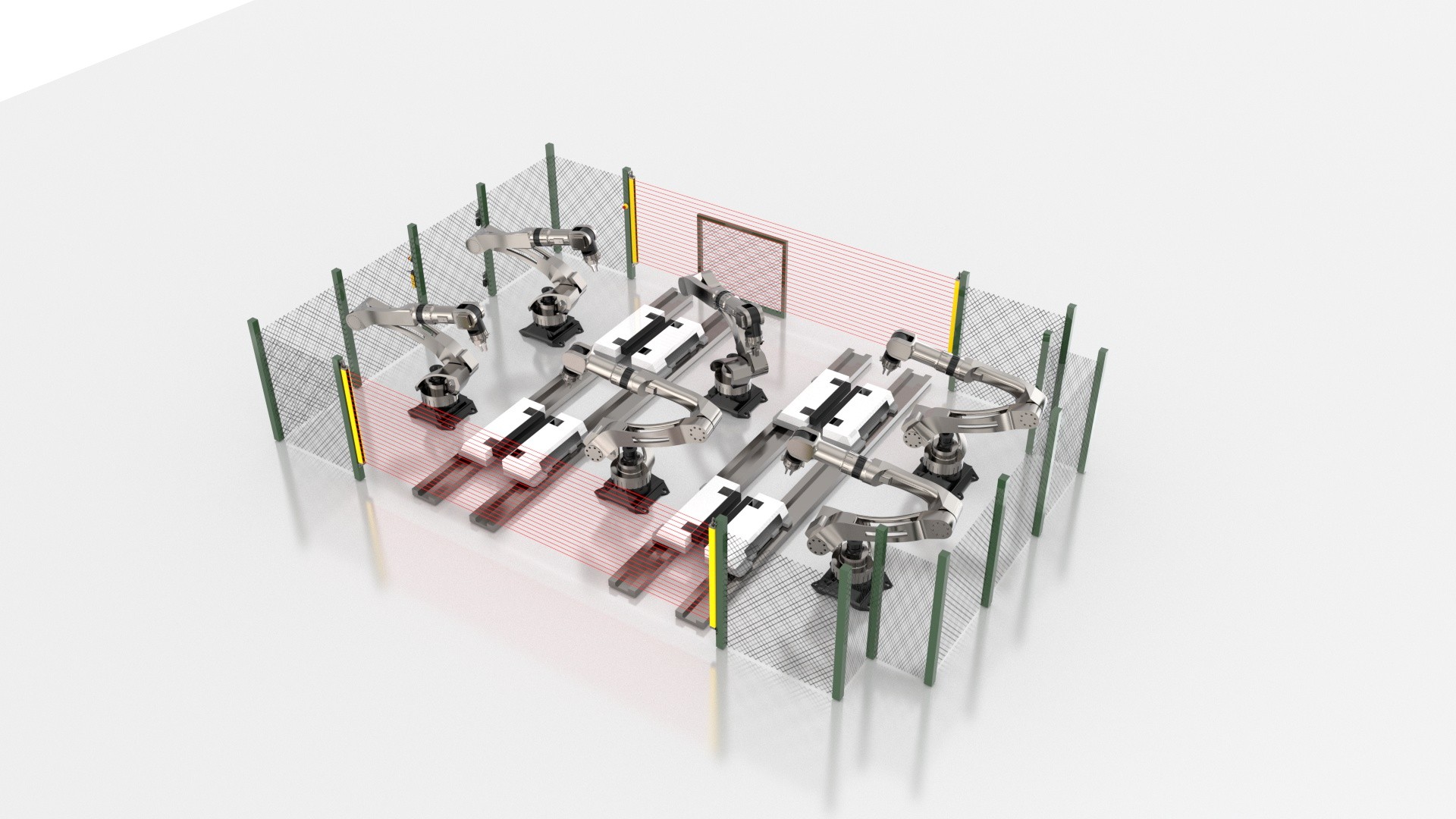

Solutions for safety protection of robot work cells

Application

Robotic work cell safety protection.

Challenge

Need to use multiple safety light curtains simultaneously.

Solution

QCE Series Safety Light Curtain

Advantages

Safety light curtains can be cascaded and connected together.

Safety light curtains are widely used and crucial in industrial automation production lines. As an advanced safety protection device, they protect workers and equipment through invisible barriers composed of infrared beams, preventing accidental injuries that may occur during the automation process.

The Importance of Safety Light Curtains in Industrial Automation Production Lines

Prevent accidental contact

Safety light curtains are usually installed around dangerous mechanical equipment. When workers or other objects on the production line accidentally enter the area protected by the safety light curtain, the safety light curtain will immediately interrupt the infrared beam and send a signal to the control system, causing the equipment to stop operating immediately to prevent any potential injuries or equipment damage.

Ensure operational flexibility

Safety light curtains not only protect the safety of personnel, but also provide flexible protection solutions without hindering normal production operations. Operators do not need to be restricted by physical barriers like traditional mechanical guardrails, and can access equipment more freely and quickly enter and exit the work area when needed, which improves the convenience and efficiency of operation.

Accurate detection

On automated production lines, safety light curtains can accurately detect any object entering the protection area, regardless of size. This high-precision detection capability ensures that even smaller objects or limbs can be detected in time, further improving safety.

Adapt to different application scenarios

Safety light curtains for industry are highly adaptable and can be used in various complex production environments. Whether in the collaborative operation of multiple devices or in the protection of a single device, safety light curtains can provide stable and reliable protection. For example, in the conveyor belt area of the assembly line, the safety light curtain can effectively detect the passage of objects and adjust the operating status of the equipment as needed to avoid misoperation or unexpected shutdown.

Improve production efficiency

By avoiding downtime and reducing accidents, the safety light curtain significantly improves the overall efficiency of the production line. Since the equipment can run continuously at a higher speed under the protection of the safety light curtain, the production process can proceed smoothly, reducing the downtime and maintenance time caused by safety accidents.

Compliance with international safety standards

Modern industry has increasingly stringent requirements for safety standards. As a protective device that meets international standards, the safety light curtain can meet the safety regulations of most countries and regions. This not only improves the safety level of the factory, but also ensures the compliance and market competitiveness of the product.

Principle of Safety Light Curtains

The working principle of the safety light curtain for industry is based on photoelectric sensing technology, and safety protection is achieved mainly through beam detection between the transmitter and the receiver. The following is its core working principle:

Transmitter and receiver

· Transmitter: The transmitter (usually installed on one side of the device) continuously emits a series of infrared or laser beams, which are arranged horizontally to form a "safety light curtain".

· Receiver: The receiver (installed on the other side of the device) is opposite to the transmitter and receives the beams emitted by the transmitter.

Beam detection

· Each beam emitted by the transmitter is detected by the receiver. When all beams reach the receiver normally, the system determines that there are no obstacles in the area and the equipment can operate safely.

· If a beam or multiple beams are blocked (for example, the operator's hand enters the safety light curtain area), the receiver will detect the beam interruption and respond immediately.

Signal processing and control

· When the receiver detects the beam interruption, the system will immediately generate an electronic signal, which will be transmitted to the control system.

· The control system will immediately issue a shutdown command to suspend the operation of the equipment to prevent the operator from being injured.

Fault Detection and Self-Test Function

Modern safety light curtain systems are usually equipped with self-test functions that can monitor the status of the transmitter and receiver in real time. Once a device fault or beam alignment problem is detected, the system will issue an alarm signal and stop the device to prevent the device from operating in an abnormal state.

Resolution and Detection Capability

· The resolution of the safety light curtain determines the minimum object size it can detect. For example, a high-resolution safety light curtain can detect finger-sized objects, while a low-resolution safety light curtain may only detect a hand or larger objects.

· The spacing and number of beams affect the resolution and coverage of the safety light curtain. Users can choose the appropriate safety light curtain type according to actual needs.

Protection Height and Area

The protection height of the safety light curtain can be adjusted according to the specific needs of the machine to cover all hazardous areas around the equipment. The protection area is usually set near the hazardous point that the operator may contact.

Safety Level

Safety light curtain systems usually have different safety levels and are certified according to international standards (such as ISO 13849-1, IEC 61496). High-level safety light curtains are suitable for high-risk environments and provide higher safety guarantees.

The application of safety light curtains in industrial automation production lines provides a strong safety guarantee for modern manufacturing, while also improving production efficiency and operational flexibility. With the continuous improvement of industrial automation, safety light curtains will continue to play a key role and become an indispensable safety protection equipment on the production line.

Recommended Safety Light Curtain

Resolution ratio: 10mm,20mm,30mm,40mm,80mm,200mm

Check the accuracy: 18mm,28mm,38mm,48mm,88mm,208mm

Number of beams: 04、06、08、10...72

Response time: ≤15ms

Housing material:Metal

Metal shell:Aluminium

Protection grade:IP65

DADISICK's Hot Selling Safety Light Curtains

Beam spacing: 80mm

Number of optical axes: 46

Protection height: 3600mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing:40mm

Number of optical axes: 24

Protection height: 920mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing: 40mm

Number of optical axes: 28

Protection height: 1080mm

Safety light curtain mirrors outputs (OSSD)2 PNP

Beam spacing: 20mm

Number of optical axes: 154

Protection height: 3060mm

Safety Curtain outputs (OSSD):2 PNP