Safety Light Curtains for Access Protection of Mobile Glass Pane Storage

- Share

- publisher

- Vicky

- Issue Time

- Sep 19,2024

Summary

The application of safety light curtains in mobile glass plate storage provides an effective means of protection for safe production in the glass manufacturing industry. Through real-time monitoring of dangerous areas, safety light curtains can ensure the safety of operators without affecting production efficiency. With the development of automation technology, the application prospects of safety light curtains in this field will be broader, escorting the safe production of enterprises.

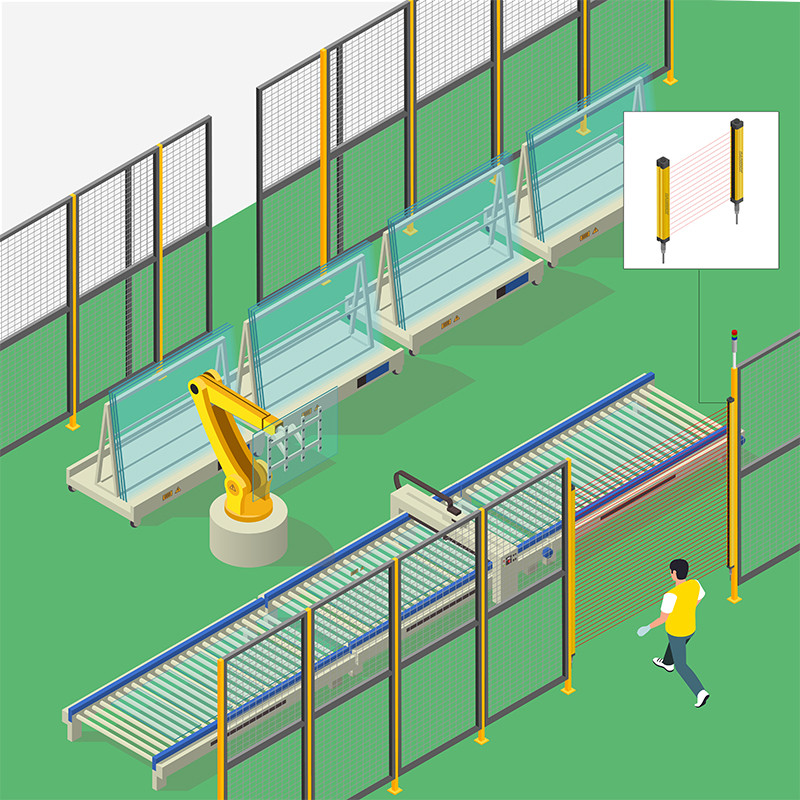

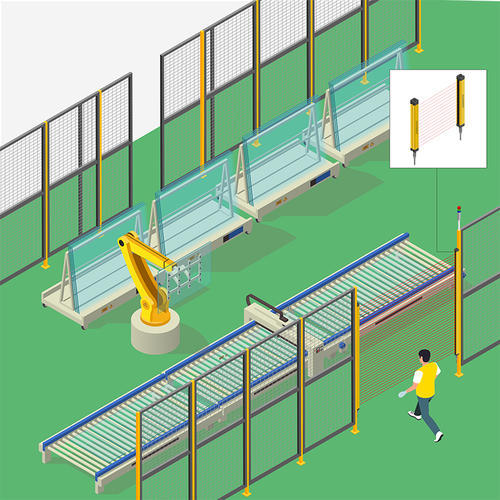

In the modern glass manufacturing and processing industry, mobile glass plate storage devices (such as glass plate stackers or automated storage equipment) are often used to efficiently store and transport large areas of glass plates. However, there are certain safety hazards when operators work in these areas, such as the movement, overturning of glass plates or accidental start-up of mechanical equipment. Therefore, ensuring personnel safety has become an important part of production. This solution uses DADISICK's QCE series safety light curtain, as a non-contact protective device, it can provide efficient access protection in the operation of glass plate storage, ensure personnel safety and optimize production processes.

Working Principle of Safety Light Curtain

The safety light curtain forms an invisible light network in the protection area through infrared beams. When an operator or other object enters the area, the beam is interrupted, triggering the safety mechanism, quickly shutting down or sounding an alarm to prevent accidents.

In the application of mobile glass plate storage, the safety light curtain can cover the channels for glass plates to enter, exit and stack, and monitor the approach of people or objects in real time. Once someone enters the danger zone, the system will take immediate action to prevent the continued operation of the mechanical equipment.

Technical Features of Safety Light Curtains

· Resolution ratio:10mm,20mm,30mm,40mm,80mm,200mm

· Check the accuracy:18mm,28mm,38mm,48mm,88mm,208mm

· Numberof beams:04、06、08、10....72

· Detection distance:300-6000mm

· Response time:≤15ms

· Output mode:2-circuit of PNP, with current of 500mA and voltage below 1.5V, polarity, short circuit and over-cutting protection

· Type of light:Infrared light(NlR),invisible

· Housing material: Metal

· Metal shell: Aluminium

· Lens front screen material: Acrylic

· Upper and lower cover materials: ABS reinforced nylon PA66+30% GF

· Protection grade: IP65

Specific Application of Safety Light Curtains in Mobile Glass Panel Storage

Protect access

Install safety light curtains at the entrance and exit of glass plate storage equipment to prevent operators from accidentally entering the danger zone when the equipment is running. The equipment will only continue to operate when it is confirmed that there are no obstacles, thus effectively protecting the operator.

Robot arm operation protection

In some automated glass plate handling systems, robotic arms are used to grab and move glass plates. Safety light curtains can monitor the working area of the robotic arms to ensure that no personnel enter the danger zone during mechanical movement.

Prevent glass plates from tipping over

Mobile glass plate storage may be at risk of tipping over when glass plates are entering and exiting. By arranging safety light curtains in key areas, any abnormal situation can be detected, such as accidental tilting or falling of glass plates, and the system will immediately take measures to stop the equipment operation.

Application Characteristics of Safety Light Curtains

Contactless protection

The safety light curtain detects through photoelectric sensors, without the need for physical guardrails, avoiding the inconvenience that traditional protection measures may cause, especially in situations where frequent access to glass panels is required.

Real-time response

When a person or object is detected entering the light curtain protection area, the system will respond immediately and stop the operation of the equipment to prevent personal injury or equipment damage.

Flexible configuration

The safety light curtain can be customized according to the layout, size and workflow of different storage equipment to ensure that all potential danger areas are covered.

Outlook on the Future Development of Safety Light Curtains

As the glass manufacturing industry's requirements for automation and safety continue to increase, the application of safety light curtains in mobile glass plate storage will become more intelligent. Future safety light curtain systems may integrate more sensor technologies, such as radar or laser scanners, to further improve the monitoring accuracy and response speed of dangerous areas. At the same time, intelligent control systems will also be closely integrated with light curtains to provide a more comprehensive safety protection solution.

DADISICK's Hot Selling Safety Light Curtains

Beam spacing:20mm

Number of optical axes: 40

Protection height: 780mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing: 10mm

Number of optical axes: 102

Protection height: 1010mm

Safety curtain outputs (OSSD): 2 PNP

Beam spacing: 40mm

Number of optical axes: 32

Protection height: 1240mm

Safety sensors for machines outputs (OSSD)2 PNP

Beam spacing:40mm

Number of optical axes: 54

Protection height: 2120mm

Safety Curtain outputs (OSSD):2 PNP