Safety Mats Application: Ensuring Efficiency and Safety of Welding Robots

- Share

- Issue Time

- Sep 2,2024

Summary

Safety mats are vital safety devices in welding robot environments, offering instant protection. They detect proximity, triggering robot stoppage to prevent accidents. Customizable layouts optimize workspaces, enhancing productivity by minimizing downtime. Integrated with other safety systems, they provide comprehensive protection. Regular inspections, proper installation, training, and electrical safety measures ensure their effectiveness.

What type of safety device is used to stop welding robots? Safety mats, as an important safety protection device, plays an irreplaceable role in the welding robot operating environment. The application of safety switch mats in welding robots has significant advantages and important practical significance. Through rational layout, regular inspection and maintenance and improve the safety awareness of operators and other measures, can give full play to its safety protection role, to ensure the safety and efficiency of welding operations.

Immediate Response and Efficient Protection of Safety Pressure Mat :

The safety mats has a built-in pressure sensor that can sense the proximity or contact of an operator or foreign object in real time. Once the preset safety threshold is triggered, the safety mat sensor will immediately send a signal to the control system, causing the welding robot to quickly stop working, effectively preventing collisions or pinching accidents. This instant stop mechanism greatly improves the efficiency and reliability of safety protection.

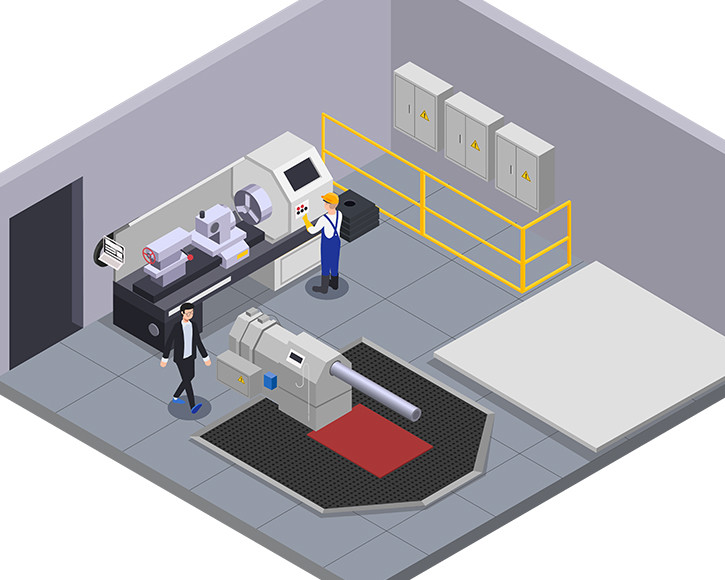

Flexible customization and area division:

The safety mats can be customized according to the specific layout and safety needs of the welding robot's work area, flexibly dividing the work area and safety zone. This helps to ensure that operators can clearly identify safety zones while working, further reducing the risk of accidents. Safety pressure mat sensor also provides individualized safety solutions for different production lines.

Integration with other safety systems:

The safety mat can be integrated with existing safety systems (such as safety light barriers, safety doors, etc.) to form a complete safety protection system. When the safety mat is triggered, it can not only stop the robot from working, but also trigger the alarm device or lighting system, further enhancing the safety prompts on site.

Reduce equipment downtime:

Safety mats can avoid frequent equipment downtime caused by personnel mistakenly entering dangerous areas, thereby ensuring the continuity and stability of production and improving production efficiency.

Improve assembly accuracy:

Safety mats can ensure that operators are in a safe position when working, avoiding assembly errors or quality problems caused by personnel moving or mistakenly entering dangerous areas. At the same time, it can also be used in conjunction with robot collaboration systems to further improve assembly accuracy and quality.

Optimize operating procedures:

The foot-operated function of the safety mat can improve operating efficiency. In some assembly links that require frequent starting and stopping of equipment, operators can control the operation of the equipment by stepping on the safety mat without manually operating buttons or switches, thereby improving assembly flexibility and efficiency.

Detection method: pressure sensing method

Maximum allowable dynamic load: impact load<200kg/cm²

PVC anti slip surface layer: anti slip grade R9

Encapsulation and Surface Protection: PVC

Under pressure: dynamic 500KG, solid 700KG

Surface material: rubber (red/yellow/black optional)

Control level: achieved level 3 in combination with controller

Class of protection: IP65

Ambient temperature: -10℃ to 60℃

Thickness: 14mm

Triggering force: adult 30KG

Cable length: 3M and 5M optional

Response time: Less than 30ms

Weight: about30kg/sq.m

As a safety protection device, safety mats industrial sensor needs to be checked regularly for sensor sensitivity, signal transmission stability and wear and tear on the pressure-sensitive mat surface. Make sure the pressure-sensitive safety mat is in good condition to cope with unexpected situations.

Reasonable layout and installation:

When installing the safety pressure-sensitive mats, it is necessary to make a reasonable layout according to the working range and safety requirements of the welding robot. Ensure that the carpet fully covers the hazardous area and avoids interference with the robot or other equipment.

Training and Awareness Raising:

All personnel associated with the welding robot must receive professional training to understand the working principle and use of the industrial safety mat. At the same time, operators' safety awareness is raised to ensure that they are able to respond correctly in the event of an emergency.

Electrical safety:

Welding robots use a large number of electrical equipment and cables, and electrical safety must be ensured to prevent accidents such as electrocution. The electrical part of the safety mat should also comply with relevant safety standards to avoid electrical failures that could cause safety problems.

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.

Safety Edges is a technology that monitors the pressure distribution on the carpet through pressure sensing.