Safety Mats Safeguard Workplace Safety and Efficiency on Press Lines

- Share

- Issue Time

- Aug 30,2024

Summary

DADISICK's blog highlights how safety mats enhance safety and efficiency on press lines. These mats are essential in various industries, stopping equipment when personnel enter hazardous areas. They boost workplace safety, reduce accidents, and ensure smooth operations. Discover how DADISICK's innovative safety mats can transform your industrial processes.

As an important safety protection device, safety carpet plays a key role in improving the safety of the production environment and reducing workplace accidents. The following is a detailed analysis of its application advantages and precautions, accompanied by an actual case.

Efficient safety protection:

By laying safety mat in the working area of the stamping production line or pressure machinery, when the staff approaches or mistakenly enters the dangerous area, the safety carpet can quickly sense the pressure change and start the emergency stop program through the controller to cut off the power supply of the machine and equipment, effectively preventing injuries due to misoperation or mistaken entry of the staff. This instant response mechanism significantly improves the safety of the production line.

Enhance production efficiency:

The application of safety switch mats not only reduces the downtime of the production line due to accidents, but also enhances the confidence of the employees so that they can concentrate more on their work, thus improving the overall productivity. At the same time, safety mat sensor reduces compensation costs and legal risks for the organization.

Safety mat switch is durability and ease of maintenance:

The body of a safety mat switch is usually made of wear-resistant and decay-resistant materials, such as black safety carpet, which can withstand the effects of frequent stepping and mechanical movement for a long period of time. In addition, it is relatively simple to lay and maintain, making it easy for companies to manage and maintain on a day-to-day basis, reducing long-term operating costs.

Flexibility & adaptability of pressure sensitive safety mat:

Safety carpet can be customized in size and shape to fit different press lines and press machine layouts. This flexibility allows safety carpet to be used in a wide range of industrial scenarios to meet diverse safety and protection needs.

Detection method: pressure sensing method

Maximum allowable dynamic load: impact load<800kg/cm²

PVC anti slip surface layer: anti slip grade R9

Encapsulation and Surface Protection: PVC, CR

Response time: 13ms

Power consumption: <20kg

Maximum allowable dynamic load: impact load <800kg/cm²

Mechanical life: >3,000,000 times

Correct installation and commissioning:

When installing the pressure-sensitive mat, it must be ensured that it is accurately positioned and firmly fixed to avoid shifting or loosening during use. At the same time, it is also necessary to carry out correct commissioning and testing of the safety carpet controller to ensure that it can accurately receive signals and activate the emergency stop program.

Regular inspection and maintenance:

Regular inspection and maintenance of the safety carpet is necessary to ensure that it is always in good working condition. Checks include wear and tear of the carpet, integrity of the connecting wiring and proper functioning of the controller.

Avoid misuse:

Employee training and education should be strengthened to enable them to understand the working principle and use of the safety carpet to avoid misuse leading to the failure of the safety carpet or triggering the emergency shutdown procedure by mistake.

Temperature and humidity control:

The environment in which the safety carpet is used should maintain a suitable temperature and humidity range to avoid extreme temperatures or humidity adversely affecting its performance. Generally speaking, the temperature range of use should be between -30℃~60℃.

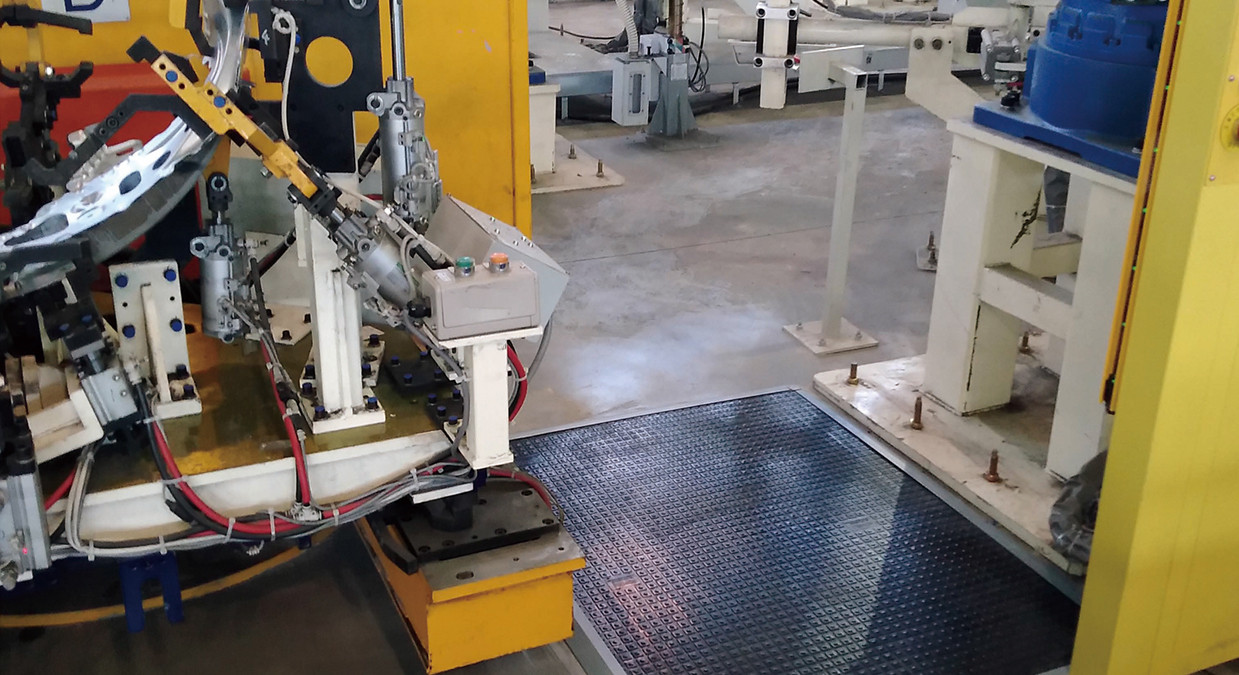

An automotive manufacturer introduced a safety carpet system on a stamping line. Custom-sized safety carpets were laid in critical areas around the production line and connected to a safety carpet controller. During production, if an employee approaches or mistakenly enters a hazardous area, the safety carpet immediately senses a pressure change and sends a signal to the controller. Upon receiving the signal, the controller quickly initiates an emergency shutdown procedure, cutting off the power supply to the presses to ensure employee safety.

Since the introduction of the safety carpet system, the automotive manufacturer has seen a significant reduction in the rate of workplace accidents and an increase in productivity. At the same time, employees feel safer in their work environment, and their motivation and satisfaction with their work has increased. This success story proves the important role and wide application of safety carpets in stamping lines and press machines.

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.

Safety Edges is a technology that monitors the pressure distribution on the carpet through pressure sensing.