Save Nearly 50% Space with This Light Curtain!

- Share

- publisher

- Zoe

- Issue Time

- Feb 8,2025

Summary

By selecting the Front Ultra-thin Safety Light Curtain QZ Series, the enterprise successfully solved the challenge of installing safety light curtains in a space-constrained production line.

Background

In automated production lines, safety is a crucial factor in both design and operation. Especially when installing safety light curtains in space-constrained equipment, it's essential to meet safety protection requirements while considering operational ease and spatial limitations. A certain manufacturing enterprise faced this challenge on its assembly line: how to install safety light curtains in a limited space to prevent operators from entering hazardous areas while ensuring that the light curtains do not interfere with each other.

Needs Analysis

The assembly line of the enterprise required the following safety protection:

1. Finger Protection: The production line requires delicate operations, so the safety light curtain needs to detect small objects like fingers to prevent injuries.

2. Operational Convenience: Operators need to operate equipment conveniently, so the safety light curtain cannot completely enclose the work area.

3. Close Installation: Two safety light curtains need to be installed in close proximity without interfering with each other.

Project Challenges

1. Finger Protection Difficulty: Detecting small objects like fingers is a challenge, as standard safety light curtains may not be effective at detecting them.

2. Space Constraints: Installing safety light curtains in limited space must not interfere with the operators' work or the normal operation of the equipment.

3. Light Curtain Interference: Installing two safety light curtains too close to each other could cause interference, affecting detection accuracy.

Solution

After evaluation, the enterprise chose the DADISICK Front Ultra-thin Safety Light Curtain QZ Series. This light curtain offers the following advantages:

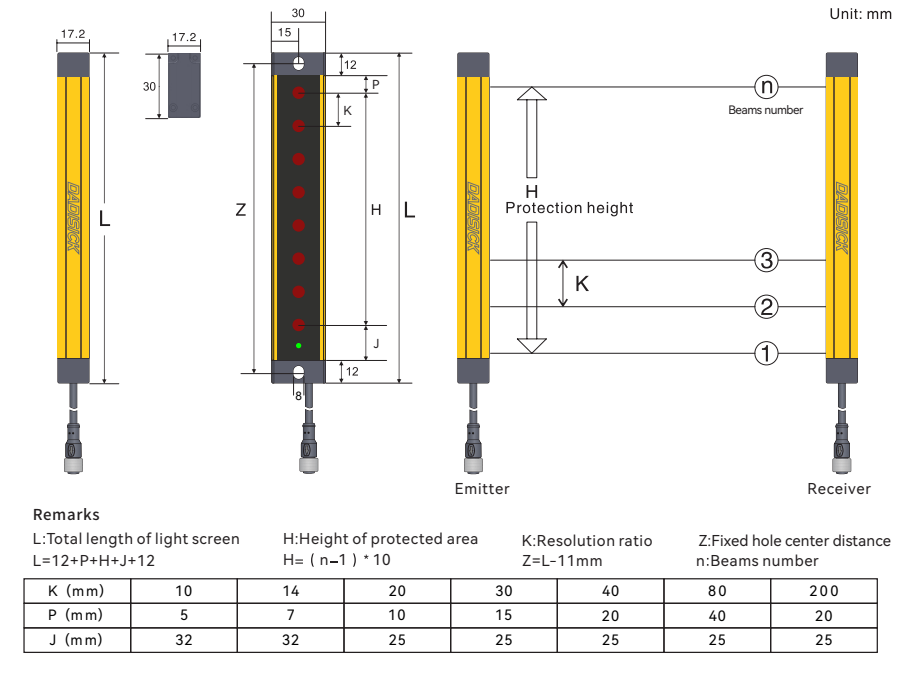

1. Ultra-thin Design: With a cross-sectional size of only 17.2x30mm, it's nearly 50% thinner than standard safety light curtains, saving significant installation space—ideal for production lines with space constraints.

2. High-Precision Detection: Capable of detecting small objects like fingers, ensuring safety during delicate operations.

3. Anti-interference Design: Even when installed in close proximity, the light curtain prevents mutual interference, maintaining accurate detection.

4. Flexible Installation: The installation method is versatile and can be adjusted according to the specific needs of the production line, ensuring safety without affecting operational convenience.

Front Ultra-thin Safety Light Curtain QZ Series

▪️Cross-sectional dimensions: 30 x 17.2 mm

▪️Short response time, with the fastest response time <15 ms

▪️Low-voltage power supply, operating voltage DC 10 - 24 V

▪️Strong electromagnetic interference resistance, effectively countering various EMI impacts from motor-driven equipment

▪️Equipped with line synchronization technology, ensuring strong light interference resistance

▪️M12 5-pin aviation connector for quick and easy wiring

50% Thinner Than Standard Safety Light Curtains

Application Cases

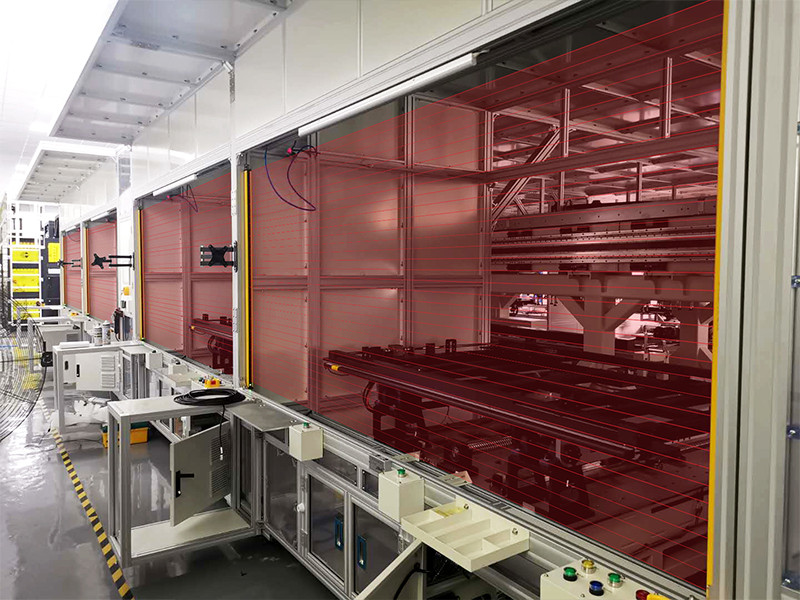

In a screen manufacturing facility, the compact safety light curtain is installed on the production equipment, creating a protective barrier to ensure the safe operation of the production line.

A leading medical device company, dedicated to manufacturing high-quality medical equipment, places operator safety as a top priority. The client required a robust solution to protect the safety of their operators, and DADISICK provided an effective safety solution.

Implementation Results

1. Space Saving: Thanks to the ultra-thin design of the QZ Series, the enterprise successfully installed two safety light curtains in the limited space, saving nearly 50% of the installation space.

2. Enhanced Safety: The light curtain effectively detects small objects like fingers, ensuring operator safety and reducing workplace injuries.

3. Operational Convenience: The installation of the light curtain did not affect the operators' normal work, ensuring the efficiency of the production line.

4. Interference-free Operation: Even when installed close to each other, the two light curtains operated stably without interference, ensuring the safe operation of the production line.

Related Safety Light Curtains

Beam spacing:10mm

Number of optical axes: 14

Protection height: 130mm

Safety-light-curtain outputs (OSSD):1 PNP

Beam spacing: 10mm

Number of optical axes: 102

Protection height: 1010mm

Safety curtain outputs (OSSD): 2 PNP

Beam spacing: 40mm

Number of optical axes: 100

Protection height: 3960mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing:20mm

Number of optical axes: 24

Protection height: 460mm

Safety sensors for machines output (OSSD):2 PNP