Type 4 Safety Light Curtain Installation: 8 Critical Steps to Ensure Machine Safety & Compliance

- Share

- Issue Time

- Jun 7,2025

Summary

This article delves into the crucial role of safety light curtains in industrial automation, emphasizing correct installation and usage precautions. It covers key preparations like safety distance calculation and environmental assessment, installation and positioning, wiring procedures, and alignment of components. Discover expert insights and techniques to optimize safety light curtain performance, ensuring robust industrial automation safety.

In the process of industrial automation production, safety light curtains play a vital role. They can effectively protect the safety of operators and avoid accidents caused by misoperation or accidental contact with dangerous parts of machinery. However, in order for the safety light curtain to fully exert its protective function, correct installation techniques and precautions are essential. This article will give you a detailed introduction to the installation points of the light curtain safety system and the precautions during use.

Safety Distance Calculation

The safety distance directly determines whether the machine safety light curtains can stop the equipment before the human body touches the danger. Determine the straight-line distance (inter-beam distance) between the type 4 safety light curtain transmitter and the receiver, as well as the required length and width of the light curtain according to the actual situation of the machine equipment to ensure that the safety light curtain operation can fully cover the dangerous area. According to the mechanical safety standard JB3350-93, the calculation formula is divided into two cases:

When the equipment can stop actively: DS=1.6(T1+T2)

When the equipment needs to stop passively: DS=1.6Ts

Among them, 1.6m/s is the internationally recognized human hand entry speed (empirical value), T1 is the light curtain reaction time, and T2 is the equipment braking time 110.

For example: For a punching machine, T1=0.02s, T2=0.15s, then the safety distance DS=1.6×(0.02+0.15)=0.272m, at least 280mm should be reserved during installation.

Safety Light Curtain Environmental Assessment

Determine the safety level: Select the safety level of the safety light curtain based on the degree of danger the equipment poses to people. The so-called "level 2" and "level 4" light curtains refer to the type 2 and type 4 safety light curtain in the IEC 61496 standard. Type 2 safety light curtain can generally reach the PLC level in ISO 13849, and some high-performance products can even reach the PLd level; while level 4 light curtains can reach the PLe level. If there is a risk of major casualties, a safety light curtain type 4 should be selected, and if there is a risk of minor casualties, a level 2 safety light curtain can be selected.

Evaluate the protection type: Select the appropriate optical axis spacing and protection height of light curtain safety module according to the part to be protected. Generally speaking, select 10mm spacing for finger protection, 20-30mm spacing for palm protection, and 40mm or greater spacing for arm or body protection.

Consider the signal output method: There are many output methods for safety light curtains, such as relay output, NPN output, PNP output, etc. The appropriate output method needs to be selected according to the control system and interface requirements of the device.

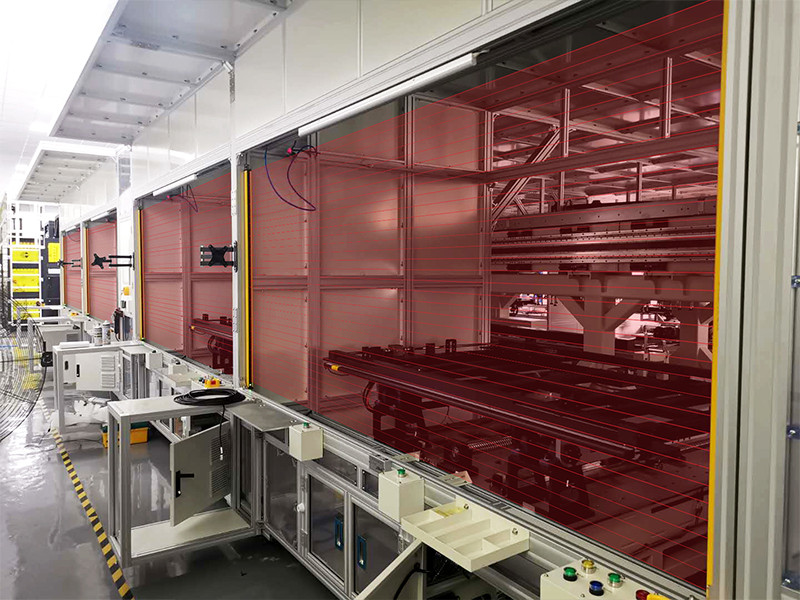

Evaluate the installation environment: Select the appropriate installation method and light curtain safety switch material based on factors such as installation space, light conditions, and electromagnetic interference. For example, when the installation space is limited, you can choose to install the L-shaped bracket side-mounted or the base rotating steel pipe bracket. In the field environment, the inverter and servo motor must be more than 2 meters away from the light curtains for safety to avoid false operation caused by electromagnetic interference. At the same time, check the reflective surface (such as stainless steel plate, glass) to prevent the refraction of the light beam from causing a blind spot. IP67 protection grade light safety curtain should be used in dusty and oily areas, and plan a regular cleaning schedule.

Consider other interference factors: Based on the equipment application environment, consider whether the safety light curtain needs to have anti-electromagnetic interference, anti-arc and laser interference, anti-sunlight interference, and waterproof and dustproof characteristics.

Detection range: 0.3 - 6m

Detection: fingers, hands

Security level: IP65

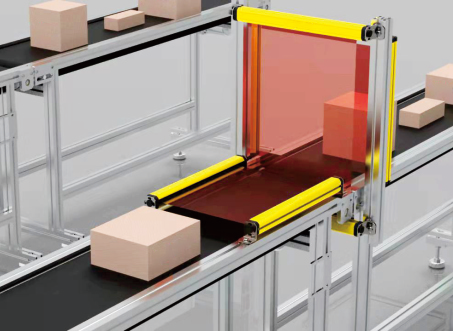

Eliminating dead zones, the QO series does this by eliminating blind spots. They can be tailored to specific application requirements and are highly flexible and customizable, including different heights, lengths, and resolutions. Additionally, they can be easily integrated with other safety devices and control systems, providing enhanced functionality and adaptability. Implement regional protection for hazardous operating areas such as industrial robots, injection molding machines, packaging equipment, automation equipment, and assembly lines.Selection of Installation Position

Ensure safety distance: The minimum distance from the plane of the light safety curtains to the dangerous area must be larger than the safety distance, which needs to be calculated based on factors such as the response time of the miniature safety light curtain, the stopping time of the machine and the detection accuracy.

Avoid mutual interference: If two or more light curtain devices are installed adjacent to each other, the installation positions of the safety curtain light emitters should be staggered and separated by a distance of more than 50cm, or the safety curtain light emitters should be placed opposite each other, back to back, with partitions in the middle, or placed up and down to prevent mutual interference.

Reduce reflection effects: Avoid installing the safety light curtain kit near objects with smooth reflective surfaces, such as metal plates, floors, ceilings, etc. If this cannot be avoided, the distance between the safety light curtain device and the reflective surface should be greater than the A (m) value calculated by the formula or obtained by looking up the coordinate graph.

Fixing of Mounting Bracket

Forward-mount bracket: If you use a forward-mount bracket, you must first determine the installation location, then drill holes with an electric drill, and then use M6×17 screws to fix the safety light curtain sensors bracket to the installation surface.

Side-mounted bracket: For the side-mounted bracket, first use M5×12 screws to fix the side-mounted bracket to both ends of the safety light curtain, then determine the installation position, drill holes and tap, and use M5×12 hexagon socket screws to fix the safety light curtain to the installation surface.

Angled bracket: After installing the T-nut into the safety light curtain, use M5×12 screws to fix the angled plate to the T-nut, then determine the installation position, drill holes and tap, and use M5×12 hexagon socket screws to fix the light curtain.

Laying Method and Path

Separate laying: Lay the sensor line of the safety light curtain separately from the power line, motor/servo line or other high-voltage lines to avoid mutual interference and prevent the safety light curtain from malfunctioning or signal instability due to electromagnetic interference.

Reasonable path planning: Starting from the transmitter and receiver of the safety light curtain workbench, plan a reasonable wiring path to the control cabinet or PLC and other control devices, try to make the line short and avoid unnecessary bends and detours.

Specific Wiring and Connection Procedures

Connect the transmitter and receiver: Connect the transmitter and receiver of safety lighting curtains through a dedicated connection cable to ensure a firm and reliable connection. The most common cable is a one-wire seven-core cable, which includes 0V, 24V, CE, CP, GND, PNP, NPN, and other wires.

Connect the power line: Connect the 0V line of the short safety light curtain to the low potential end of the power supply, and the 24V line to the high potential end of the power supply.

Connect the signal wire: Select PNP or NPN signal wire for connection according to the control system requirements. Usually only the PNP or NPN wire on the transmitter is connected, because the signal of the receiver will be synchronized to the emitter.

Connect the ground wire: Connect the GND wire to a valid ground terminal to ensure that the device is safely grounded.

Connect to the Control System

Connect to a safety relay or safety PLC: Connect the output signal line (OSSD) of the safety light curtain to a safety relay or safety PLC. When the safety rated light curtains is blocked, the safety relay disconnects the control circuit and the device stops immediately.

Directly connect to a normal PLC (use with caution): In low-risk scenarios, the safety light curtain can also be directly connected to a normal PLC, but it is not recommended to directly control the main power circuit because its safety level is relatively low.

Mechanical alignment: Starting from a common reference point, place the transmitter and receiver on the same plane with their midpoints facing each other and the connector ends pointing in the same direction. You can verify that they are mechanically aligned using a carpenter's level, plumb ball, or optional laser alignment tool.

Electrical alignment: Turn on the voltage supply to the safety light curtain, roughly align the transmitter with the receiver, and adjust the position of the receiver so that the alignment status LED lights up.

Precautions

1. During the wiring process, carefully check the connection position of each line to ensure that it is correct to avoid the light curtain not working properly or malfunctioning due to wrong wiring.

2. The cables of the safety light curtain usually have color coding and line markings, and each line can be accurately connected based on this auxiliary information.

3. After the wiring is completed, perform a functional test, block the light beam with your hand or an object, and observe whether the equipment stops in time to ensure that the safety light curtain can work properly. If there is no action, check the wiring logic or output mode.

4. Use cable ties or cable troughs to organize the cables to prevent false alarms or disconnections caused by looseness later.

Beam spacing: 2.5mm

Number of optical axes: 32

Protection height: 77.5mm

Beam spacing: 30mm

Number of optical axes: 42

Protection height: 1230mm

Safety light curtain outputs (OSSD)2 PNP

Beam spacing:40mm

Number of optical axes:20

Protection height:760mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing:20mm

Number of optical axes: 10

Protection height: 180mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing: 80mm

Number of optical axes: 10

Protection height: 720mm

Safety Curtain outputs (OSSD):2 PNP