Using Safety Laser Scanners for Safety Zone Monitoring on Metal Cutting Conveyors

- Share

- publisher

- Zoe

- Issue Time

- Aug 29,2024

Summary

The LDS2030B5-5S is a compact measurement-type single-layer scanning LiDAR, specifically designed for AGV (Automated Guided Vehicle) mobile applications, while also capable of providing safety protection and monitoring for static hazardous areas.

Risks Associated with Metal Cutting Machine Operation

Hazards from Debris and Sparks During the Cutting Process:

During the cutting process, the high-speed rotating cutting disc generates metal debris and sparks. These particles can scatter into the surrounding area, potentially striking workers and causing injuries such as cuts, burns, or even more severe harm.Mechanical Energy of the Cutting Disc and Its Drive Mechanism:

The cutting disc and its drive mechanism (e.g., motors, transmission systems) possess significant mechanical energy during operation. Improper handling by workers or equipment malfunctions may lead to disc rupture or ejection, resulting in serious mechanical injuries.Limitations of Traditional Safety Measures:

In environments with such potential risks, worker safety is a top priority. However, traditional safety measures, such as physical barriers or mechanical limit switches, may not always provide comprehensive protection.Safety Laser Scanners for Safety Zone Monitoring

Requirements

In a scenario provided by one of our metalworking clients, the conveyor belt and cutting machine are positioned against a wall on one side, with an open walkway on the other. This layout presents significant safety hazards. Consequently, the client has requested that workers be prohibited from walking freely in the area in front of the conveyor belt and cutting machine to prevent accidents.

Solution

Application of DADISICK Safety Laser Scanners: DADISICK safety laser scanners can be utilized for the following safety tasks: Within a flat area (where the angle between the flat protection area and the ground is less than 90°), if the safety laser scanner detects an object entering the protection zone, it will switch the OSSD (Output Signal Switching Device) to the off state, thereby stopping the machine's operation.

✅ Compact measurement-type single-layer scanning LiDAR, specifically designed for AGV mobile applications, safety surveillance, and safety protection.

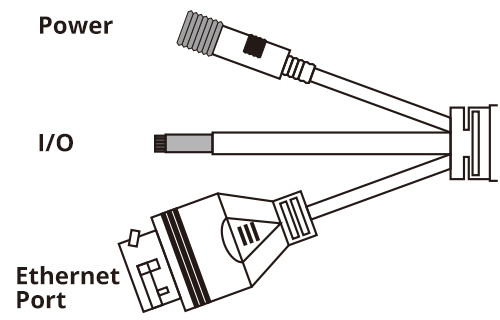

✅ Configured and outputs measurement data via an Ethernet port; features built-in obstacle avoidance and area monitoring functions, supports monitoring signal output and alarm control based on I/O ports, and can guide network cameras for video positioning and tracking of monitored targets.

✅ Utilizes 905nm infrared laser, with an operating range of 0.1 to 20 meters and a 300° ultra-wide scanning angle, coupled with a 25Hz scanning frequency to meet the needs of fast and efficient applications.

✅ Equipped with self-diagnostic capabilities, compact size, lightweight, and wide voltage input range to adapt to various application scenarios. Supports power-saving and life-extension controls, making it easy to integrate into mobile applications.

✅ Rated at IP67 for protection, resistant to sunlight and dirt, supports penetration through rain, fog, and dust, and includes built-in heating, making it suitable for outdoor environments.

|

Socket

|

Type

|

Description

|

|

Power |

DC002

|

2-core

|

|

Ethernet Port |

RJ45 Socket

|

4-core

|

|

I/O |

SM2.45,5P

|

10-core

|

Safety-Related Sensors

20m distance, A technique that uses a laser beam to measure distance and create detailed maps of objects and environments.

Beam spacing: 10mm

Number of optical axes: 70

Protection height: 690mm

Safety light curtain mirrors outputs (OSSD)2 PNP

Beam spacing: 20mm

Number of optical axes: 72

Protection height: 1420mm

Safety Curtain outputs (OSSD): 2 PNP

Beam spacing:10mm

Number of optical axes: 200

Protection height: 1990mm

Safety Curtain outputs (OSSD):2 PNP