Using Ultrasonic Sensors to Detect the Presence of Liquid Containers

- Share

- publisher

- Zoe

- Issue Time

- Aug 21,2024

Summary

DADISICK's ultrasonic sensors accurately detect the presence of liquid containers, effectively preventing production issues caused by missing containers. The sensors offer high stability and durability, making them suitable for complex environments and ensuring smooth production processes.

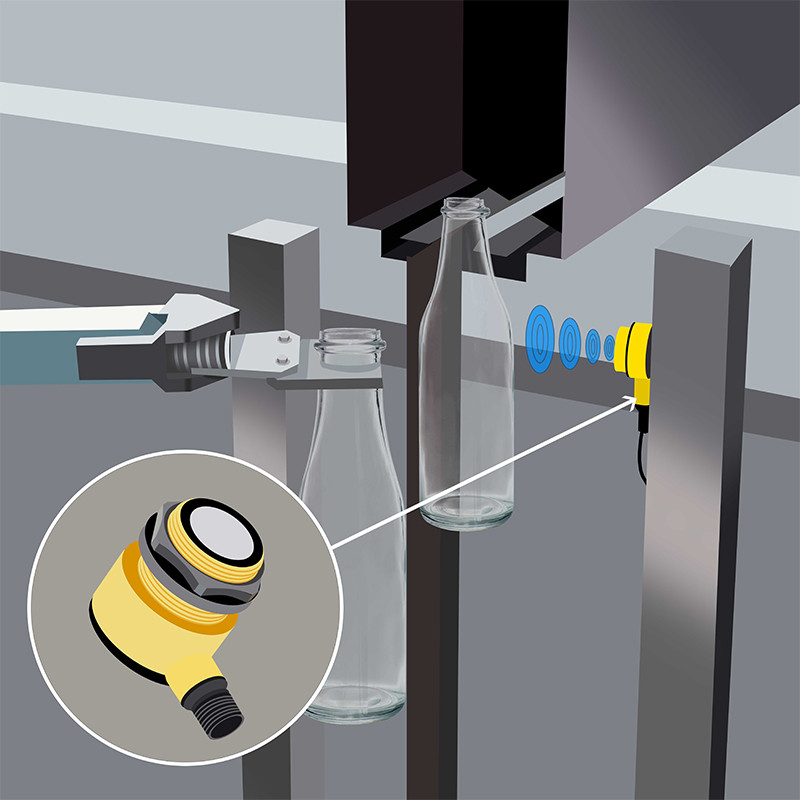

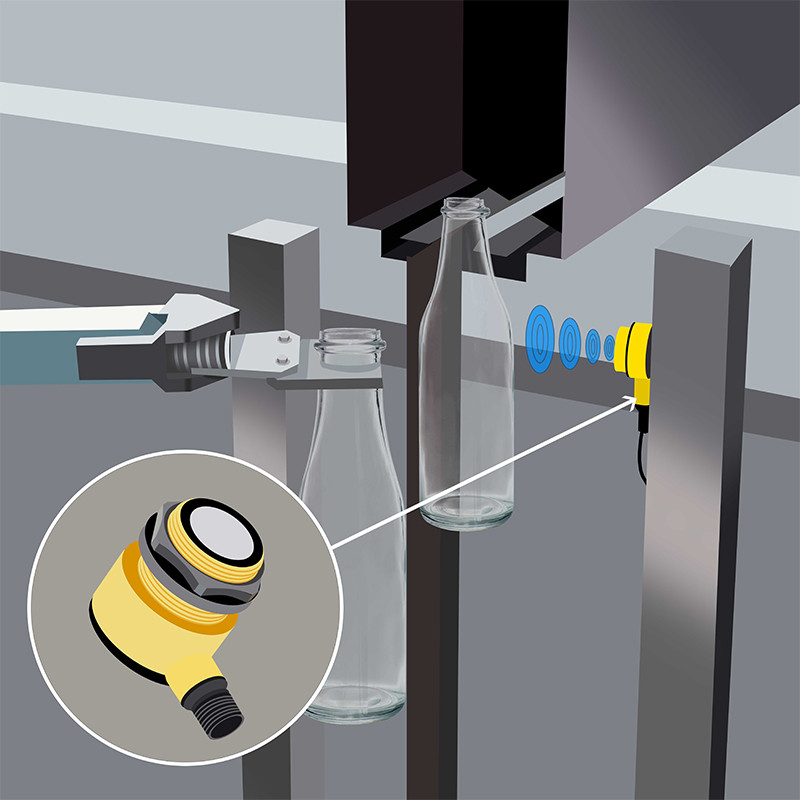

Using Ultrasonic Sensors to Detect the Presence of Liquid Containers

In industries such as pharmaceuticals, cosmetics, and beverages, it is crucial to confirm the presence of a container before filling it with liquid. DADISICK's ultrasonic sensors, with nickel-plated brass housings, can accurately detect the presence of containers from above. This helps to effectively prevent production interruptions, liquid waste, or equipment damage caused by the absence of a container during the filling process. Our ultrasonic sensors offer high stability and durability, ensuring reliable operation in various complex environments and facilitating smooth production processes.

Recommended Ultrasonic Sensors

Detection range: 20-120 mm

Detection range: 20-200 mm

Material: copper nickel plating

Connection type: 4-pin M12 connector

Detection range: 30-300 mm, 50-500 mm, 60-1000 mm

Material: copper nickel plating, plastic fittings

Connection type: 5-pin M12 connector

Detection range: 100-2000 mm, 200-4000 mm, 350-6000 mm

Material: copper nickel plating, plastic fittings

Connection type: 5-pin M12 connector

Detection range: 100-2000 mm, 150-3000 mm

Material: plastic accessories, filled with epoxy resin

Connection type: 5-pin M12 connector