What Are Safety Light Curtains Used For?

- Share

- publisher

- Vicky

- Issue Time

- Sep 7,2024

Summary

Safety light curtain is an efficient and reliable safety protection equipment, which is indispensable in modern industry. It not only prevents injuries, but also improves production efficiency and reduces maintenance costs. With the development of industrial automation, safety light curtain will be widely used to provide comprehensive safety protection for enterprises.

What Is a Safety Light Curtain?

A safety light curtain, also known as a photoelectric safety protection device, is a device that uses infrared beams to detect and protect hazardous areas. It usually consists of a transmitter and a receiver. The transmitter emits multiple parallel infrared beams that form a "light wall" between the receivers. Once an object or person enters and blocks these beams, the system will respond immediately, usually triggering an emergency stop or other preset safety measures to prevent possible danger.

Working Principle of Safety Light Curtain

The working principle of the safety light curtain is based on photoelectric sensing technology. Specifically, the transmitter continuously emits modulated infrared light, and the receiver is responsible for receiving these light beams. When all light beams can reach the receiver normally, the system believes that there are no obstacles or people in the protection area and can allow the equipment to operate normally. Once a light beam is blocked by an object or a person, the light signal received by the receiver will change, and the system will respond immediately, output a signal to the control system, stop the operation of the equipment or trigger other safety measures.

Main Functions of Safety Light Curtains

Prevent accidental injuries

The core function of the safety light curtain is to protect operators from mechanical equipment. For example, in high-risk mechanical operations such as punching machines or shearing equipment, the safety light curtain can immediately stop the operation of the equipment when it detects that someone has mistakenly entered the dangerous area, thereby avoiding accidents.

Improve work efficiency

In addition to protecting the safety of operators, the rapid response capability of the safety light curtain also helps to reduce downtime caused by safety accidents. This not only improves production efficiency, but also reduces the cost of equipment maintenance.

Adapt to diverse application scenarios

The safety light curtain can be customized according to different application scenarios, such as adjusting the density of the light beam, the emission height, etc. This enables it to adapt to various complex working environments, including automated production lines, packaging equipment, logistics systems, etc.

Application Areas of Safety Light Curtains

Mechanical processing equipment

In the mechanical processing industry that requires frequent operation and contact with dangerous equipment, safety light curtains are an important tool to ensure the safety of operators.

Automated production line

On the automated production line, the safety light curtain can monitor the production environment in real time to ensure that no one enters the dangerous area during the operation of the equipment.

Logistics system

In the warehousing and logistics system, the safety light curtain can be used to monitor the flow of goods and prevent people from mistakenly entering the operating range of automated transportation equipment.

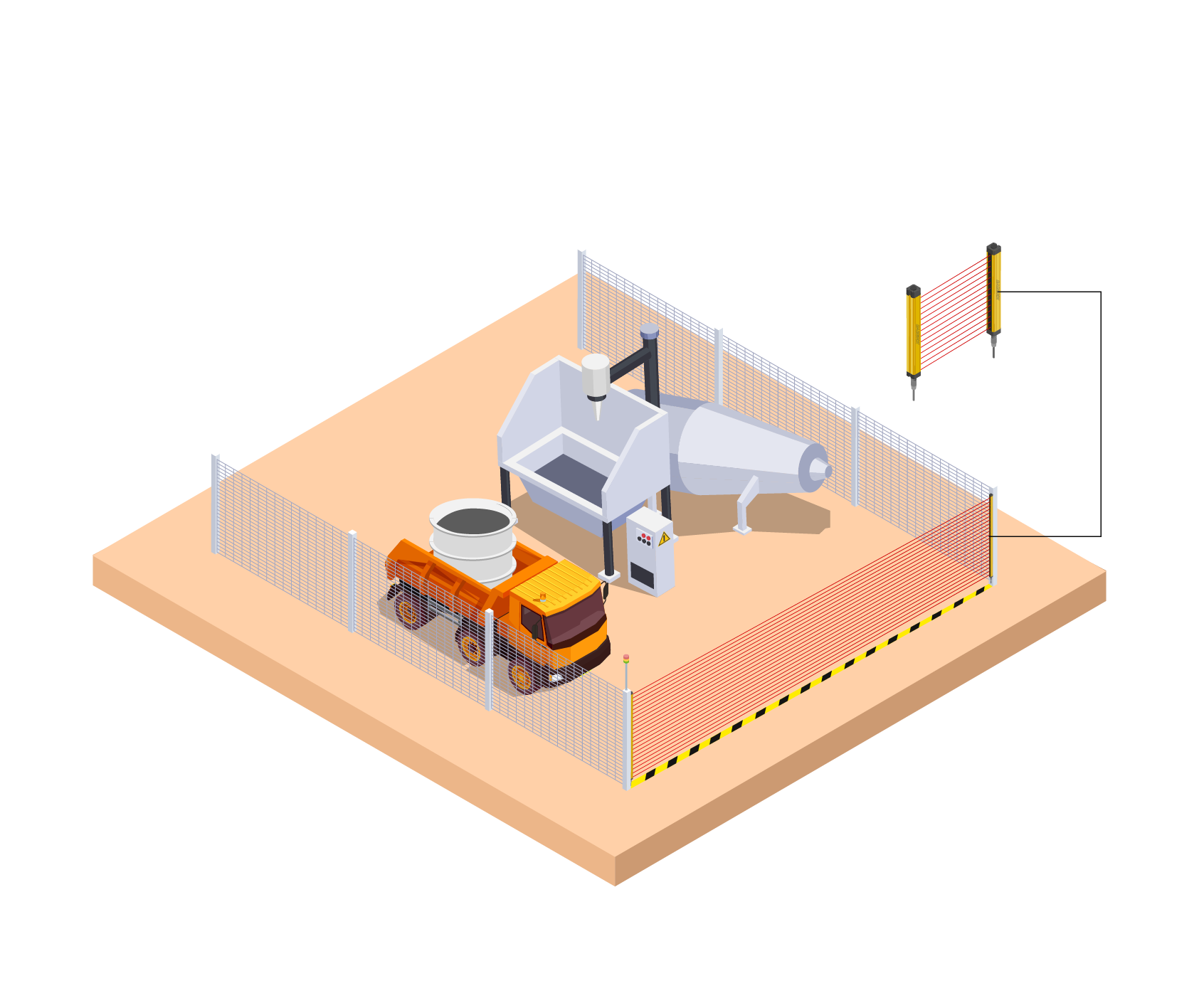

Robot work area

With the popularization of industrial robot applications, safety light curtains are also widely used in robot work areas to prevent people from mistakenly entering the robot's operating range and causing danger.

DADISICK's Hot Selling Safety Light Curtains

Beam spacing:40mm

Number of optical axes: 56

Protection height: 2200mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing: 80mm

Number of optical axes: 50

Protection height: 3920mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing: 40mm

Number of optical axes: 32

Protection height: 1240mm

Safety sensors for machines outputs (OSSD)2 PNP

Beam spacing: 10mm

Number of optical axes: 164

Protection height: 1630mm