What Is the Difference Between Type 2 Safety Light Curtains and Type 4 Safety Light Curtains?

- Share

- publisher

- Vicky

- Issue Time

- Aug 31,2024

Summary

Type 2 safety light curtains are low cost, use a single CPU processor, have dual safety channel outputs, can be self-diagnosed or externally tested for fault detection, and are suitable for medium or low risk situations. Type 4 safety light curtains are more expensive, use dual CPU processors, have more reliable control and a higher level of fault detection, are suitable for high-risk situations, and provide stronger protection for hazardous areas.

What is safety Light Curtain Definition?

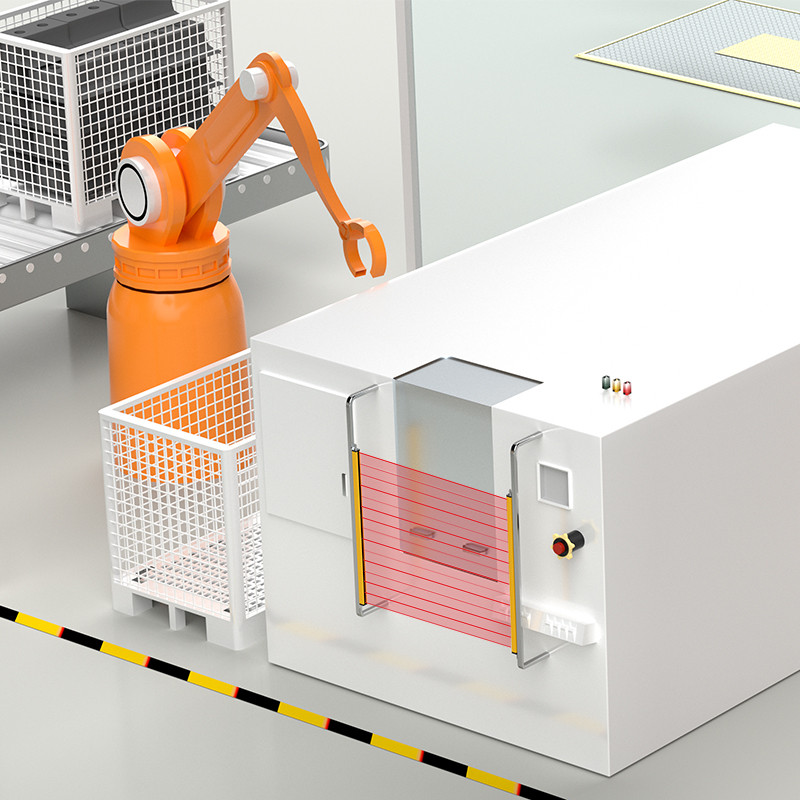

Safety light curtain, also called safety grating, is a photoelectric safety protection device. It also has many names, such as safety protector, punch protector, infrared protection device, etc. It is a newly developed high-quality automatic control product that uses infrared scanning detection technology.

In modern factories, people and machines work together on some potentially dangerous mechanical equipment, such as stamping machinery, shearing equipment, metal cutting equipment, automated assembly lines, automated welding lines, mechanical transmission and handling equipment, and dangerous areas (toxic, high pressure, high temperature, etc.), which are easily used in environments that cause personal safety of operators. The role of the safety light curtain is to stop the machine quickly when the operator enters the dangerous area due to operating errors, thereby achieving the purpose of protecting the normal operation of people and machines.

The main difference between Type 2 and Type 4 safety light curtains is the performance level (PL) and the risk level of the application scenario. The following is a detailed comparison between the two:

Features of Type 2 Safety Light Curtain

1. The price is relatively low, suitable for scenarios with limited budget but still need basic protection;

2. Performance: single CPU processor;

3. Dual safety channel output;

4. Self-diagnosis or external cycle test can be used for fault inspection;

5. Troubleshooting method to ensure safety performance;

6. Application scope: Occasions and machines with medium or small damage, automated production equipment, material picking and placing devices, etc.

7. Response time: Faster, but not as fast as Type 4;

8. Resolution and detection height: Customizable, usually meets basic needs

Features of Type 4 Safety Light Curtain

1. More expensive, but suitable for high-risk and legally mandated situations where a high level of protection is required;

2. Performance: dual CPU processor;

3. Dual safety channel output;

4. More reliable control, slightly less affected by interference light;

5. Self-diagnosis for fault inspection, higher level redundant fault mutual inspection, etc.;

6. Application scope: High-risk occasions or occasions where the machine is seriously damaged, such as hydraulic presses, punching machines, automatic welding lines, bending machines and other heavy machinery, which play a good protective role in dangerous areas.

7. Response time: Faster, meeting higher security requirements;

8.Resolution and detection height: Higher resolution, capable of detecting small objects such as fingertips

Summary and suggestions

Type 4 safety light curtains are suitable for applications involving human proximity to high-speed or high-pressure equipment, such as stamping and cutting.

Type 2 safety light curtains are suitable for applications with lower risks and only basic area detection, such as light machinery and auxiliary equipment.

DADISICK's Hot Selling Safety Light Curtains

Beam spacing:20mm

Number of optical axes: 6

Protection height: 100mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing: 40mm

Number of optical axes: 72

Protection height: 2840mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing:200mm

Number of optical axes: 16

Protection height: 3000mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing: 40mm

Number of optical axes: 100

Protection height: 3960mm

Safety Curtain outputs (OSSD): 2 PNP