What is a Safety Mat? An Industrial Safety Mats Comprehensive Guide

- Share

- Issue Time

- Jul 4,2025

Summary

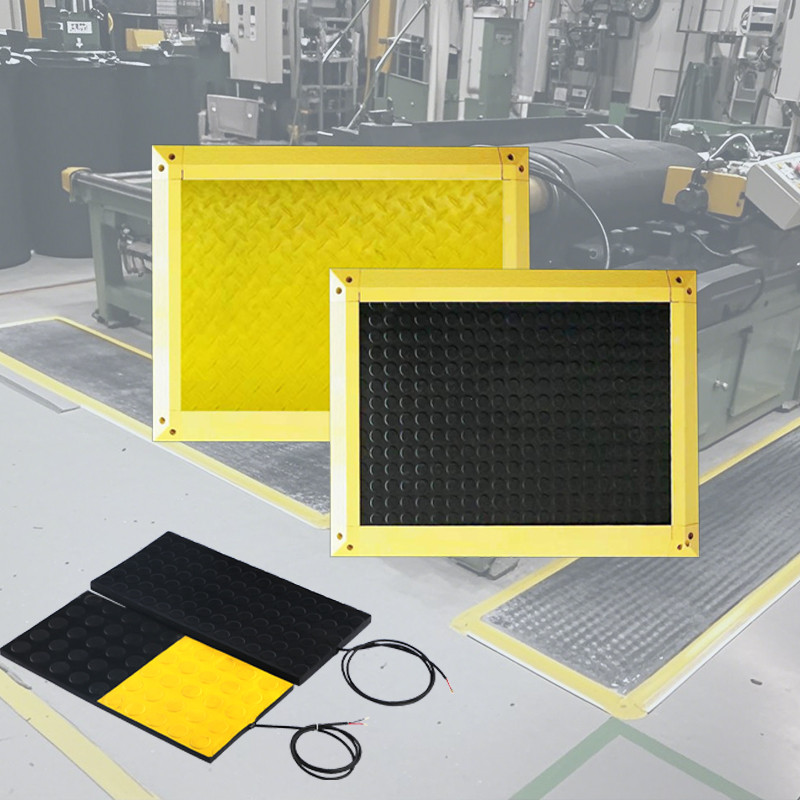

Discover high-quality industrial safety mats from DADISICK. Our pressure-sensitive safety floor mats offer high trigger sensitivity, flexible laying area, durability, and fail-safe design. Perfect for machine operation control, automated assembly line guarding, and robot area guarding. Explore our customized solutions and superior quality products to enhance industrial safety.

Safety Mats Introduction

In industrial settings, ensuring the safety of workers is paramount. One effective solution for protecting personnel in hazardous areas is the use of safety mats. These pressure-sensitive devices play a crucial role in safeguarding employees and equipment. This comprehensive guide delves into the intricacies of safety mats, their applications, and how our company, DADISICK, contributes to advancing industrial safety with innovative safety mat solutions.

What Are Safety Mats?

Safety mats are pressure-sensitive safety protection devices. When a set minimum weight is exceeded on the safety mat, the switch turns off, and the controller sends a stop signal to the protected machine. This action effectively halts the machine's movement, providing reliable protection for operators from various potential hazards. They are indispensable in industrial applications where automatic equipment requires the highest safety protection standards.

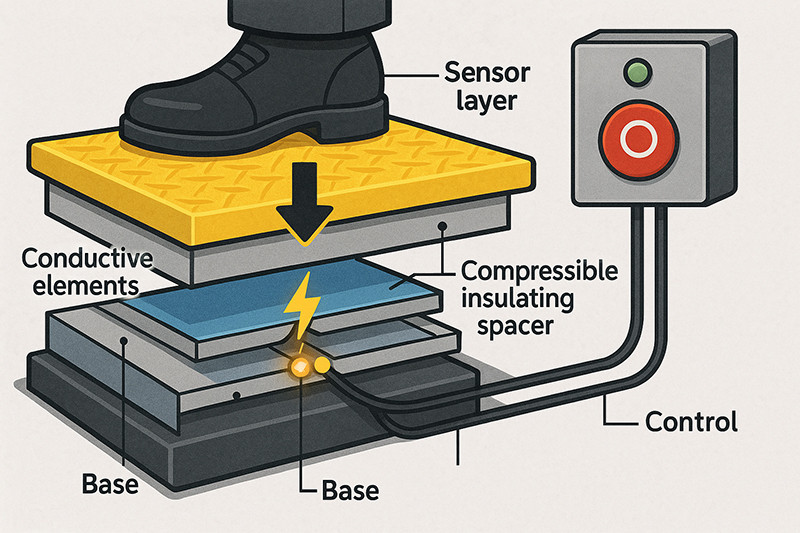

How Do Industrial Pressure Mat Sensor Work?

Safety mats function by detecting pressure applied to their surface. When an operator steps onto the mat, the pressure causes conductive plates within the mat to come into contact. This contact completes an electrical circuit, sending a signal to the controller. The controller then processes this signal and sends a stop command to the machinery, preventing any potential accidents.

The electrical circuit within the safety mat system is meticulously designed to ensure fail-safe operation. A constant current flows through the sensor, keeping the relay coil energized during normal conditions. Upon actuation of the sensor due to pressure, the relay coil is shorted, causing it to de-energize. This de-energization triggers the machine's stop mechanism, ensuring immediate protection.

Applications of Pressure Sensor Mat

Safety mats find extensive applications across various industries. They are commonly used in the following scenarios:

Machine Operation Control

Safety mats can be placed around machines to ensure that operators are in a safe position before the machine starts. This prevents accidents caused by unintended activation of machinery.

Automated Assembly Line Guarding

In automated assembly lines, safety mats can detect the presence of workers and halt the line if someone enters a hazardous area, ensuring compliance with safety protocols.

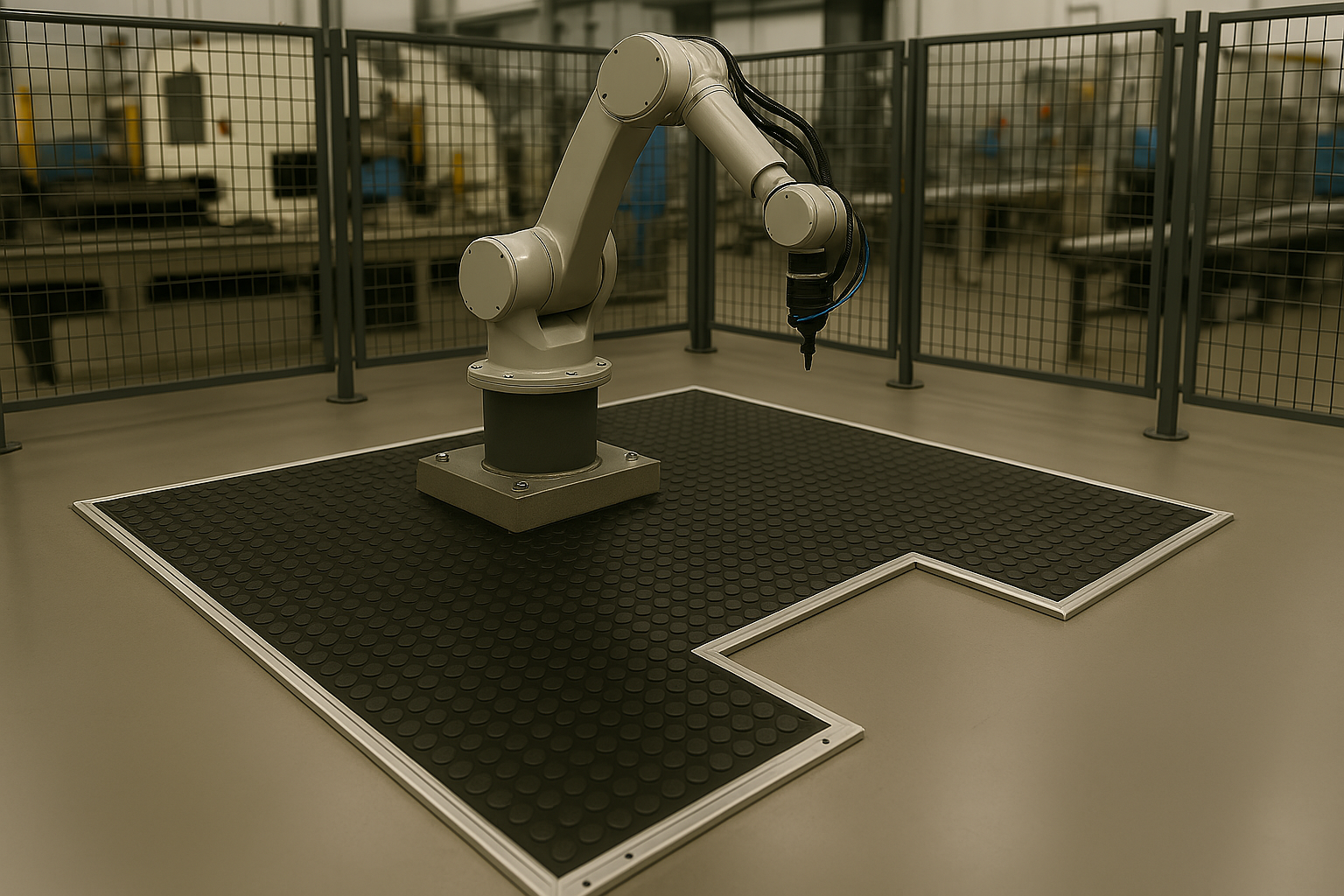

Robot Area Guarding

As robots operate in industrial environments, safety mats provide a boundary that, when crossed, signals the robot to stop, preventing collisions and ensuring safe human-robot collaboration.

General Hazardous Area Guarding

Safety mats can be installed in areas with potential hazards, such as near moving parts or dangerous machinery, to detect the presence of personnel and trigger safety measures.

Key Features of Industrial Safety Mats

Safety mats are designed with several key features that make them effective and reliable safety devices:

High Trigger Sensitivity

Safety mats can detect weights as low as 20 kg (44 lbs), ensuring that they respond promptly to the presence of personnel. This high sensitivity is crucial for immediate activation of safety protocols.

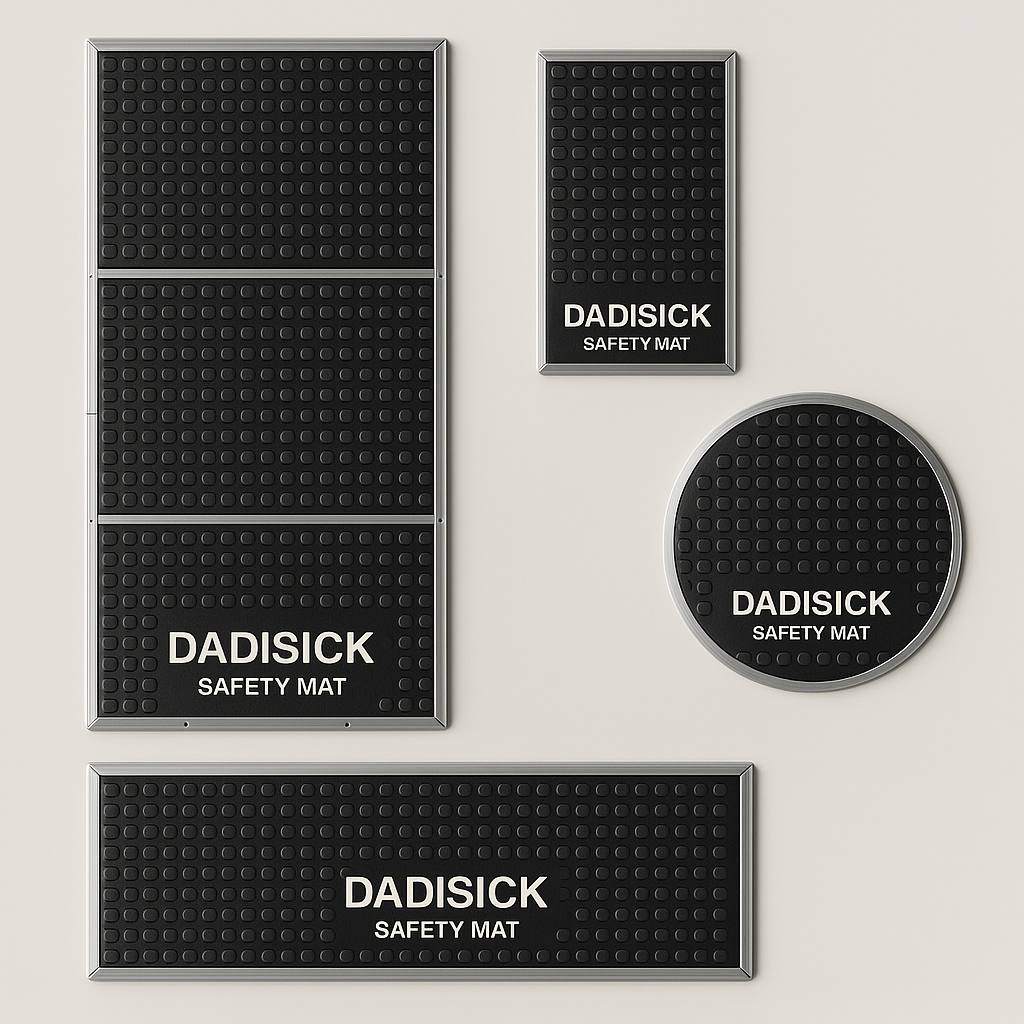

Flexible Laying Area

Safety mats can be customized in various sizes and shapes to fit specific application requirements. Whether it's a small workstation or a large industrial area, safety mats can be tailored to provide comprehensive coverage.

Durability and Longevity

Constructed with robust materials, safety mats are designed to withstand the rigors of industrial environments. They can endure heavy foot traffic, varying temperatures, and exposure to chemicals, ensuring long-term reliable performance.

Fail-Safe Design

The fail-safe concept incorporated into safety mats ensures that any failure in the system will result in a safe state. This means that if there is a loss of power, sensor failure, or other issues, the machine will automatically shut down, preventing potential accidents.

Choosing the Right Pressure Sensitive Safety Mats System

Selecting the appropriate pressure sensitive safety mats system involves considering several factors:

Working Conditions

Assess the environmental conditions of the installation area, including temperature, humidity, and potential exposure to chemicals or oils. Different safety electrical mats models are designed to suit various working conditions, from general indoor use to heavy-duty outdoor applications.

Detection Range and Sensitivity

Determine the required detection range and sensitivity based on the specific application. Some applications may require higher sensitivity to detect lighter weights, while others may need a broader detection range to cover larger areas.

System Configuration

Consider the system configuration, including the number of safety mats needed and the type of safety relay to be used. The compatibility between the safety mat and the safety relay is crucial for optimal system performance.

Certifications and Standards

Ensure that the safety mat system complies with relevant industry standards and certifications, such as ISO 13849-1 and EN 13855. These standards guarantee that the safety mat system meets the necessary safety requirements and performance levels.

Installation and Maintenance of Pressure Sensing Mats

Proper installation and regular maintenance are essential for the effective functioning of pressure sensing mats:

Installation Steps

Follow the manufacturer's guidelines for installing safety mats. This typically involves preparing the installation site by ensuring a flat and clean surface, laying the safety mat in the designated area, connecting the wiring to the control unit, and testing the system to ensure proper operation.

Maintenance Practices

Regular maintenance of safety mats includes inspecting the mat for damage, cleaning the surface to remove debris or contaminants, checking the wiring connections, and testing the system's functionality. Routine inspections and tests help identify any potential issues before they lead to system failures.

Troubleshooting Common Issues

Be familiar with common issues that may arise with safety mats, such as no start or no stop conditions. Troubleshooting guides provided by the manufacturer can assist in diagnosing and resolving these problems efficiently.

DADISICK's Industrial Safety Floor Mats Solutions

At DADISICK, we are committed to providing top-notch industrial safety floor mats solutions for industrial environments. Our safety mats are engineered with precision and quality to meet the diverse needs of various industries. Here's how our company stands out in the market:

Customized Solutions

We understand that each industrial setting has unique requirements. That's why we offer customized safety mat solutions, including tailored dimensions, sensitivity levels, and response times. Our team works closely with clients to deliver safety mats that perfectly fit their specific applications.

Superior Quality and Performance

Our safety mats are manufactured using high-quality materials and undergo rigorous testing to ensure durability and reliability. We pride ourselves on delivering products that exceed industry standards and provide consistent performance in harsh industrial conditions.

OEM Services

DADISICK provides OEM services, allowing clients to integrate our safety mats seamlessly into their existing systems. We offer customized product selection and laser marking to meet specific branding needs, ensuring a professional and cohesive safety solution.

Compliance with Standards

All our safety mats adhere to relevant industry standards and regulations. This compliance guarantees that our products meet the highest safety requirements and can be trusted to perform reliably in any industrial setting.

Excellent Warranty

We stand behind the quality of our safety mats with a comprehensive warranty. This warranty covers manufacturing defects and issues, giving our clients peace of mind and confidence in their investment.

The Future of Industrial Safety Mats

As technology advances, safety mats continue to evolve. Future developments may include enhanced connectivity with industrial automation systems, improved sensor accuracy, and more sophisticated safety protocols. DADISICK is at the forefront of these innovations, we are committed to continuously developing and improving safety mat technology to meet the ever-changing needs of industrial safety.

Conclusion

Safety mats are indispensable tools in industrial safety management. They provide a reliable and effective means of protecting personnel and equipment in hazardous environments. By understanding the principles, applications, and proper usage of safety mats, industries can significantly reduce the risk of accidents and create safer workplaces.

DADISICK is dedicated to being a leader in the safety mat industry. With our commitment to quality, innovation, and customer satisfaction, we strive to provide the best safety mat solutions that help businesses achieve their safety goals. Choose DADISICK for your industrial safety needs and experience the difference our products can make.

Visit our website at DADISICK to explore our extensive range of safety mats and discover how we can tailor a solution to meet your specific requirements. Ensure the safety of your workforce with DADISICK's reliable and high-performance safety mats.