What is a Type 2 Safety Light Curtain?

- Share

- publisher

- Vicky

- Issue Time

- Aug 29,2024

Summary

Although the Type 2 safety light curtain does not have the highest level of safety protection, it provides economical and effective safety protection for operators in medium-risk environments. Enterprises can choose the appropriate safety light curtain model according to specific application scenarios, risk assessments, and safety standards to ensure production safety.

Type 2 safety light curtain is a photoelectric safety device with a lower safety level and suitable for medium-risk industrial applications. It is mainly used in some scenarios with lower risks, such as working environments where the risk of machine operation is relatively low and the consequences of injury are not serious.

Features of Type 2 Safety Light Curtains

Medium safety level (SIL1 / PL c)

Type 2 safety light curtains meet PL c (performance level) in the international safety standard ISO 13849-1 and SIL 1 (safety integrity level) in IEC 61508, and are suitable for medium-risk applications. These standards ensure that the equipment can protect personnel safety under limited conditions.

Applicable scenarios

Type 2 safety light curtains are generally used in mechanical equipment with low operating frequency and low danger, such as some automated assembly lines, material handling equipment or light mechanical processing equipment. In these occasions, the risk of accidents is low and Type 2 light curtains provide sufficient protection.

Beam density

Compared with Type 4 safety light curtains, Type 2 safety light curtains usually have a larger beam spacing, so the detection accuracy is lower, which is suitable for the detection of larger objects or human parts, but not for delicate operations.

Response time and sensitivity

The response time of Type 2 safety light curtains is usually slightly longer than that of Type 4 light curtains, which means that it is suitable for relatively low-risk environments and does not require very fast detection and response.

Application of Type 2 Safety Light Curtains

Low-speed machinery

Such as small automation equipment, light packaging machinery, and simple conveyor systems.

Medium-risk environments

Suitable for situations where operators need to occasionally contact mechanical equipment, but the risk of the machine is not high.

Logistics systems

Such as cargo sorting and handling systems, where the approach of personnel will not directly lead to serious consequences.

Working Principle of Type 2 Safety Light Curtains

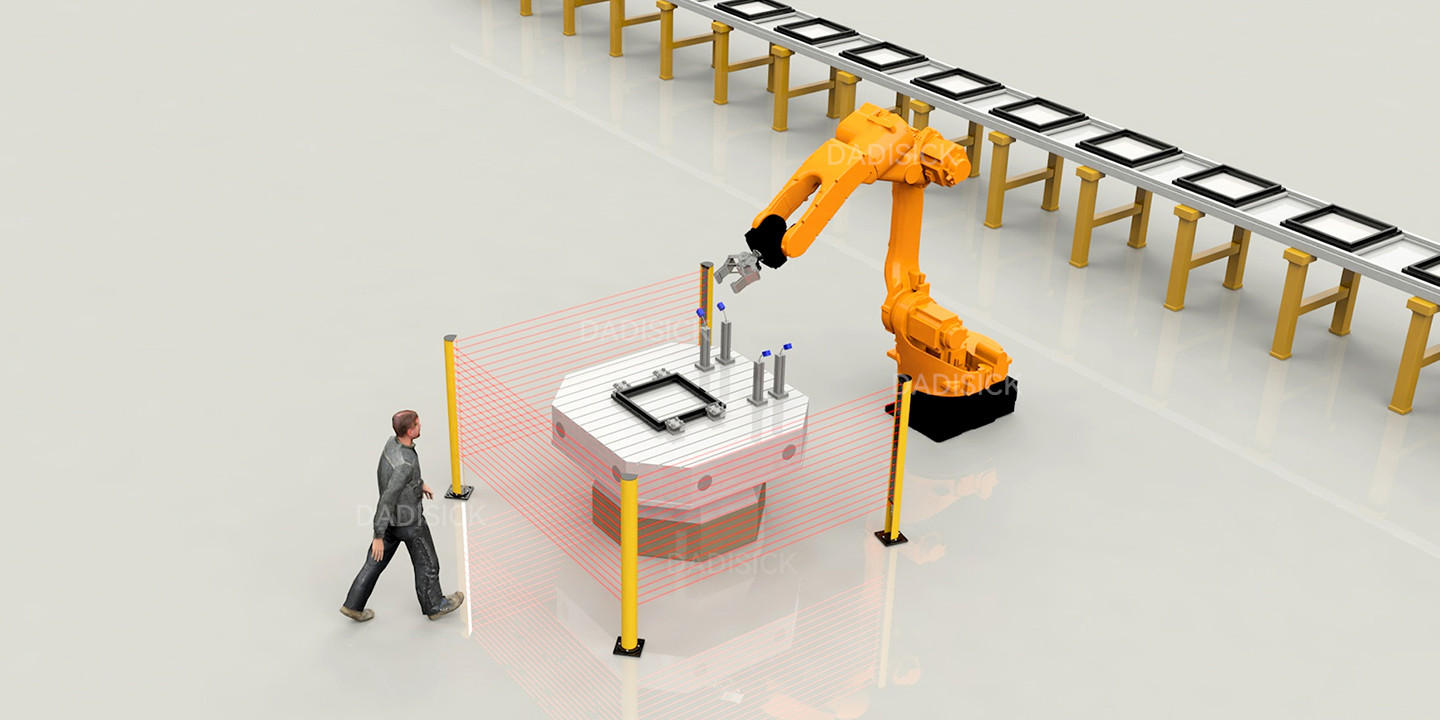

Like all safety light curtains, Type 2 safety light curtains consist of a transmitter and a receiver. The transmitter emits a series of parallel infrared beams, and the receiver receives these beams. Once an object or person enters the protection area covered by the beam, the beam is blocked. After the receiver detects this change, it will send a signal to the control system, triggering the equipment to stop operation or take other safety measures.

DADISICK's Hot Selling Safety Light Curtains

Beam spacing: 80mm

Number of optical axes: 10

Protection height: 720mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing: 40mm<br>

Number of optical axes: 68<br>

Protection height: 2680mm<br>

Curtain sensor outputs (OSSD)2 PNP

Beam spacing: 40mm

Number of optical axes: 42

Protection height: 1640mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing: 10mm

Number of optical axes: 164

Protection height: 1630mm