What is the Difference Between Optical Synchronization and Wire Synchronization in Safety Light Curtains?

- Share

- publisher

- Zoe

- Issue Time

- Aug 28,2025

Summary

Discover the differences between optical and wiresynchronization in safety light curtains. Learn principles, pros and cons, applications, and how to select the right type.

Safety Light Curtains Optical Synchronization vs Wire Synchronization: Key Differences, Applications, and Selection Guide

In the field of industrial safety protection, the synchronization method of safety light curtains directly affects reliability, stability, and adaptability. Optical synchronization and wire synchronization are the two mainstream technologies, each with distinct advantages. This article explains their working principles, performance differences, application scenarios, and key considerations for selection.

1. Understanding Synchronization in Safety Light Curtains

Synchronization ensures that the emitter and receiver of a safety light curtain operate in a unified rhythm. If the timing is misaligned — for example, the emitter sends the 3rd light beam while the receiver is expecting the 5th — it may cause false alarms or missed detections. Synchronization aligns the "clock signals" of both devices, and the difference between optical sync and wire sync lies in how this clock signal is transmitted.

Optical synchronization embeds a special synchronization beam within the regular infrared beams. The receiver detects this signal and adjusts its timing accordingly.

● No extra wiring is required, making installation faster and more flexible.

● Effective range is usually 5–15 meters.

● Common in applications where wiring is difficult, such as AGVs, robotic arms, or compact workstations.

Wire synchronization uses a dedicated cable (e.g., RS485 or special sync wire) to directly transmit synchronization signals in electrical form.

● Offers microsecond-level precision.

● Provides strong anti-interference capability, unaffected by dust, ambient light, or electromagnetic noise.

● Suitable for long distances (up to 50 meters or more) and harsh environments like welding shops or heavy machinery workshops.

2. Performance Comparison: Optical Sync vs Wire Sync

| Dimension | Optical Synchronization | Wire Synchronization | ||

| Signal Transmission | Synchronization beam within light curtain | Dedicated sync cable (electrical signal) | ||

| Installation Complexity | Easy – no extra wiring | More complex – requires additional cabling | ||

| Anti-Interference | Susceptible to dust, sunlight, strong EMI | Highly resistant to EMI, dust, and light interference | ||

Working Distance | Short-range (≤10–15m) | Long-range (up to 50m+) | ||

Scalability | Typically supports 2–4 cascaded units | Can connect 10+ units for large safety networks | ||

Typical Scenarios | Small machines, clean labs, mobile equipment | Welding shops, large assembly lines, complex automation cells | ||

3. Typical Application Scenarios

Optical Synchronization

● Mobile or space-constrained equipment where wiring is difficult.

● Logistics sorting lines and AGV systems, where cables could tangle or restrict movement.

● Electronics or lab testing equipment, where clean environments reduce interference risks.

Wire Synchronization

● Automotive welding workshops, where strong electromagnetic interference and dust are present.

● Large-scale safety networks requiring multiple light curtains to be cascaded.

● Long-distance installations where receivers and emitters are separated by more than 10–15 meters.

4. Selection Guidelines

When choosing between optical sync and wire sync safety light curtains, consider the following three dimensions:

1. Installation Space: If wiring is difficult or mobility is needed, optical sync offers greater flexibility.

2. Environmental Interference: In high-EMI or dusty environments, wire sync ensures stability and reduces false alarms.

3. Detection Range: For distances beyond 10–15 meters, wire sync is more reliable.

In some cases, hybrid models supporting both optical and wire synchronization are available, giving users the flexibility to switch modes depending on the environment.

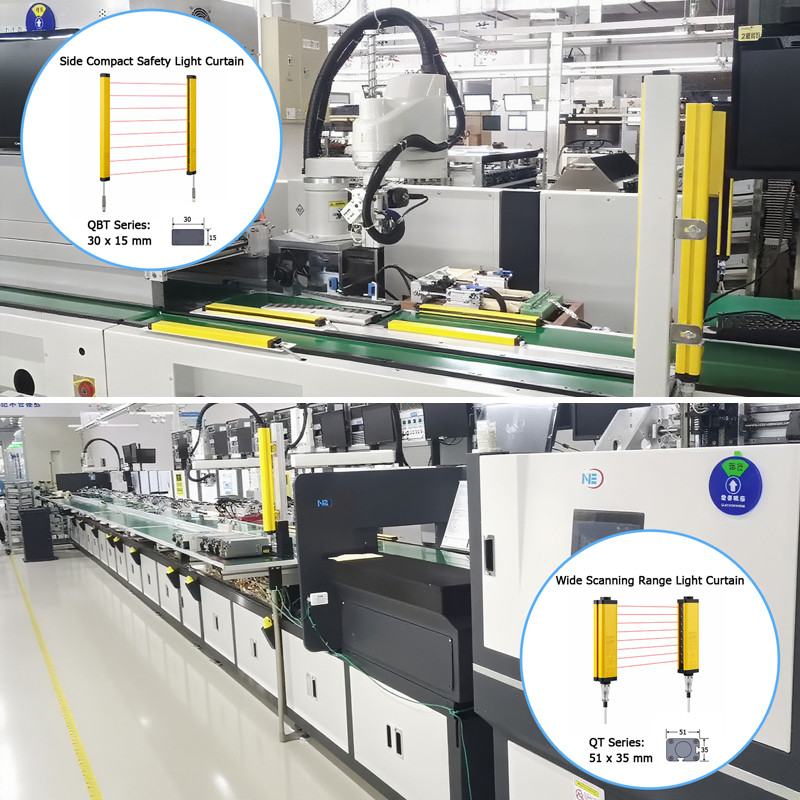

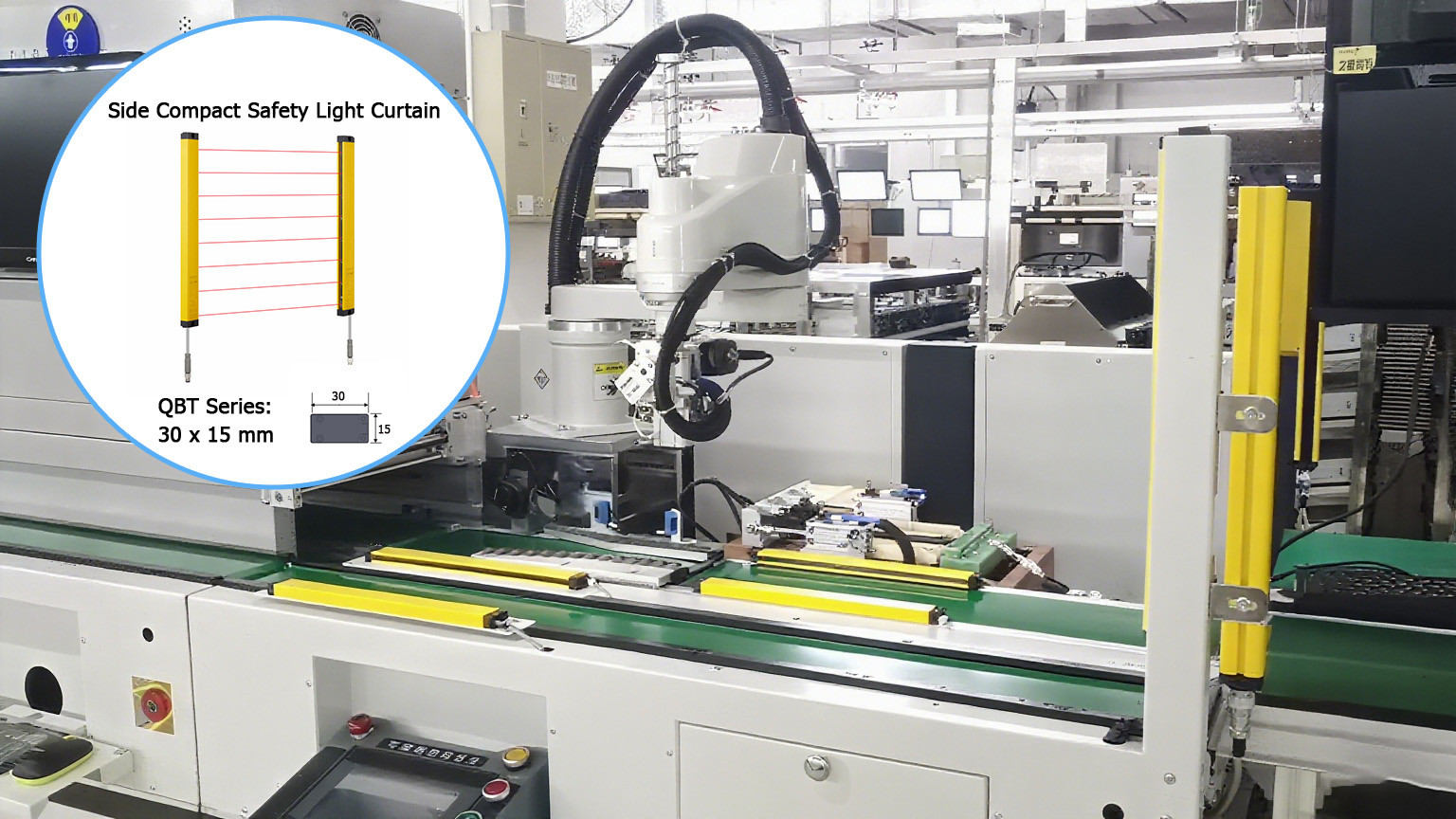

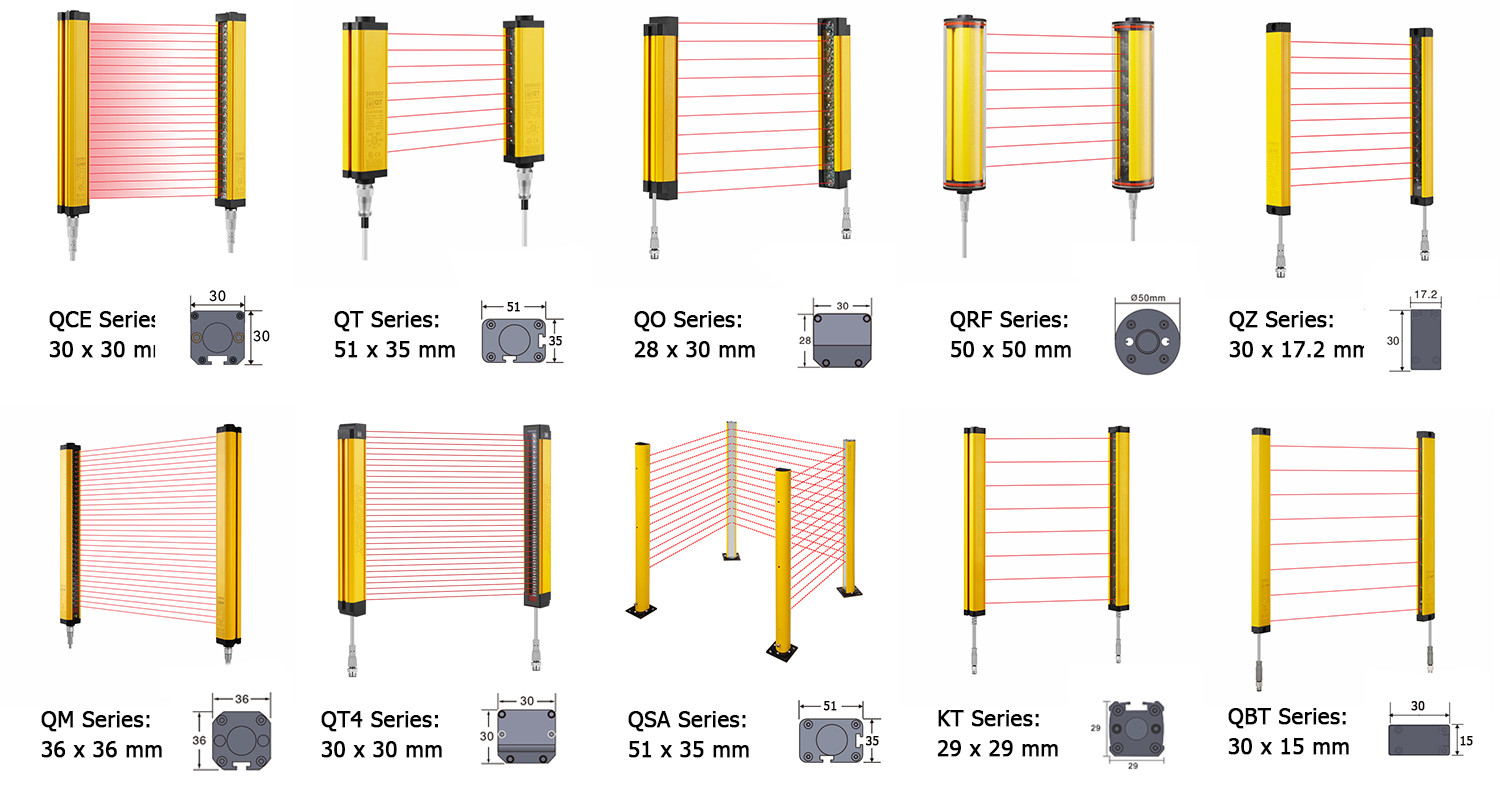

| Product series | Feature | Detection range | Optical axis spacing | Connection | Synchronization | |||

General Purpose Safety light Curtain | 0.3 - 6m | 10 / 20 / 30 / 40mm | M12, 7-Pin, 3m | Wire Sync | ||||

Wide Scanning Range Light Curtain | 0.3 - 45m | 10 / 20 / 30 / 40 / 80 / 200mm | M16, 7-Pin, 3m | |||||

Eliminate Dead Zones light Curtain | 0.3 - 6m | 10 / 20 / 30 / 40mm | M12, 7-Pin, 3m | |||||

Waterproof Safety Light Curtain | 0.3 - 6m | 10 / 20 / 30 / 40 / 80 / 200mm | M12, 7-Pin, 3m | |||||

Front Ultra-Thin Safety Light Curtain | 0.3 - 3m | 10 / 14 / 20 / 30 / 40 / 80 / 200mm | M12, 5-Pin, 3m | |||||

High-Precision Safety Light Curtain | 0.3 - 6m | 2.5 / 5 / 10 / 20 / 40 / 80mm | M12, 7-Pin, 3m | |||||

QT4 Series | High-Performance Light Curtain | 0.3 - 6m | 7.5 / 15 / 30mm | M12, 9-Pin, 3m | ||||

Multi-Sided Access Protection | 0.3 - 45m | 20 / 40 / 80 / 200mm | M16, 7-Pin, 3m | |||||

Economical Safety Light Curtain | 0.3 - 6m | 10 / 14 / 20 / 40mm | M8, Emitter 3-Pin, Receiver 5-Pin, 3m | Optical sync | ||||

Side Compact Safety Light Curtain | 0.3 - 3m | 10 / 20 / 40mm | M8, Emitter 3-Pin, Receiver 5-Pin, 3m | |||||

5. Conclusion

There is no absolute “better” option between optical synchronization and wire synchronization in safety light curtains. Instead, the right choice depends on application fit:

Optical sync = Flexible, cost-effective, and suitable for short distances in clean environments.

Wire sync = Stable, precise, and reliable in complex, long-distance, or interference-heavy conditions.

When making a decision, avoid simply chasing “high-end” models. Instead, evaluate your installation requirements, environmental conditions, and detection distance to maximize synchronization performance.

DADISICK Safety Light Curtains provide both optical and wire synchronization options, with customized solutions for different industries. For wiring diagrams, technical support, and detailed product specifications, visit www.dadisick.com

or consult our engineering team for tailored recommendations.