Summary

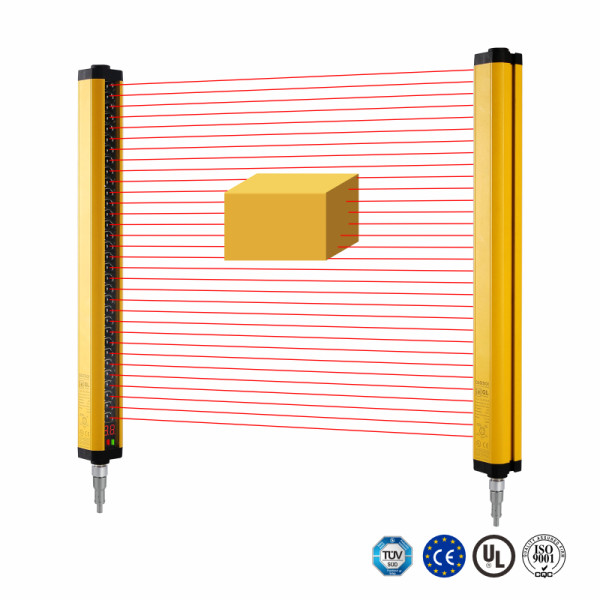

The cold stamping industry has always been a key area in the manufacturing industry, covering various metal sheet forming and processing processes. In this highly automated and precise environment, ensuring worker safety is crucial. Safety light curtains , especially DADISICK's model QT32-20-620-2BB, play a key role in the cold stamping industry, improving workplace safety and efficiency.