Summary

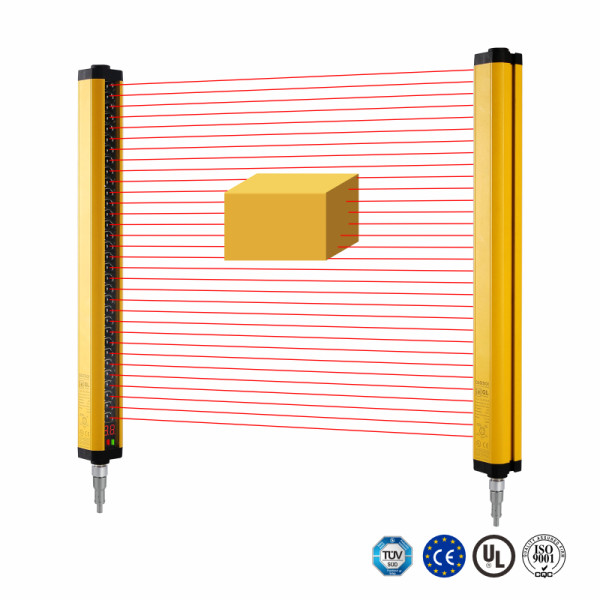

The customer is a Logistics Company, and they face huge challenges when processing large orders. The order volume is constantly increasing, requiring higher speed and accuracy. Manual sorting can no longer meet the demand, and they urgently need an innovative solution to improve efficiency.