Keyence Launches GL-V Series Safety Light Curtains to Enhance Industrial Safety and Visual Management

- Share

- publisher

- Vicky

- Issue Time

- Jul 4,2025

Summary

Keyence launches the GL-V series of safety light curtains, which feature high visibility, stability and compact design, support fast alignment and anomaly detection, and help industrial sites achieve more efficient safety management.

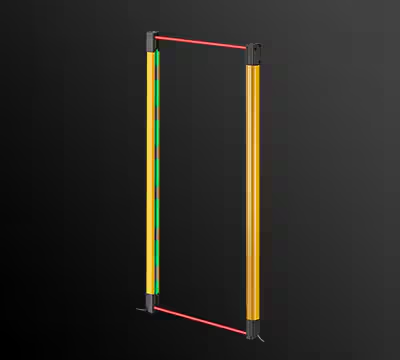

As industrial automation is rapidly evolving, the balance between equipment safety and production efficiency has become a key concern for enterprises. To meet the market demand for smarter and easier-to-deploy safety solutions, Keyence, a leading brand in the sensor field, has launched a new generation of GL-V series safety light curtains, focusing on key advantages such as dynamic visualization, safety and intuitiveness, and sturdy structure, which has attracted great attention from the industry.

Features of Keyence GL-V Safety Light Curtains

Integrated indicator lights for clear status

The GL-V series takes the visualization of light curtain status as its core highlight. Its embedded large multi-color LED indicator lights can intuitively display the current light axis status and operation information, simplify the debugging process, and improve on-site response efficiency. Even in bright and complex environments, it can accurately identify shading, normal or fault status.

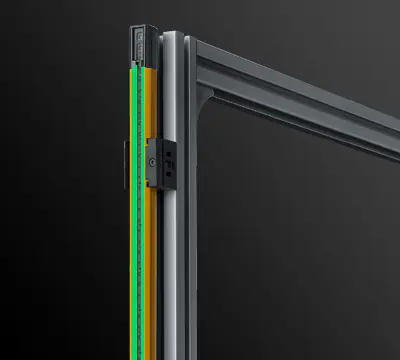

Abnormalities such as wiring errors and optical axis misalignment can be detected at startup.

Red light flashes when wiring is incorrect

The green light will light up at intervals when the optical axis is offset

During the alignment process, the grating calibration can be easily completed in three steps. Each step of the operation will be intuitively fed back through the changes in the indicator light, making the alignment process smoother.

When aiming at the top layer, the red light on the top will light up

Then aim at the bottom layer, and the green light will light up at intervals.

After fine-tuning the rotation direction, all green lights will light up

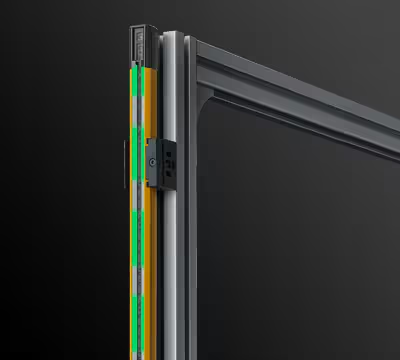

During operation, it can not only detect the light input and light blocking status, but also identify abnormal conditions such as whether there are stains on the transmitting and receiving ends, or whether the optical axis is offset.

Green light turns on when light enters

The green light will light up at intervals when dirt is attached or the optical axis is offset.

When blocking light, the red light will be on outside the blocking area

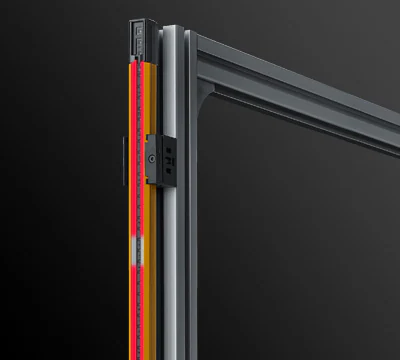

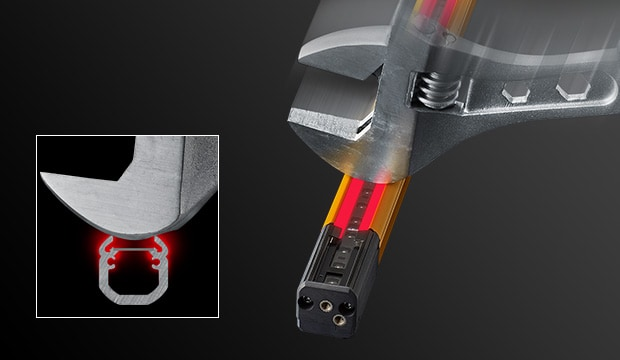

Compact body, sturdy and durable

This series not only ensures full functionality, but also adopts a sturdy and impact-resistant compact housing design (22×22mm), taking into account both structural strength and installation convenience. The oil-resistant and wear-resistant protective design also makes it capable of handling harsh industrial environments such as high pollution and high vibration.

The ultra-small size (22×22 mm) design allows for flexible installation; the metal housing provides excellent ruggedness and durability.

Since the light-emitting surface is the most vulnerable key part of the grating, a reasonable double buffer structure can effectively protect it.

Effective "no blind spot" protection

Compared with traditional safety light curtains, GL-V further optimizes the edge detection area to ensure that the sensor covers the extreme edge in actual installation, eliminating the commonly existing "blind spot" hidden dangers and effectively improving the safety level of operators.

Note: Some of the information in this article is referenced from keyence brand public information, which is intended to share industry technology and interpret products. The copyright belongs to the original company and will be deleted if infringed.

Source reference: Keyence GL-V Series Safety Light Curtains Industry News

Related Safety Products

Beam spacing: 40mm

Number of optical axes: 72

Protection height: 2840mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing:40mm

Number of optical axes:20

Protection height:760mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing: 20mm

Number of optical axes: 20

Protection height: 380mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing: 30mm

Number of optical axes: 56

Protection height: 1650mm

Area sensor outputs (OSSD)2 PNP