Application of Safety Light Curtains in Asynchronous Machines and Die-Cutting Protection in the Optoelectronic Materials Industry

- Share

- publisher

- Vicky

- Issue Time

- Aug 14,2024

Summary

Safety light curtain is a photoelectric sensing device used for machine protection and personnel safety. Through the reasonable application of safety light curtains, the asynchronous die-cutting process in the optoelectronic materials industry can not only effectively ensure the safety of operators, but also improve the automation and safety of the entire production process, reduce downtime and improve production efficiency.

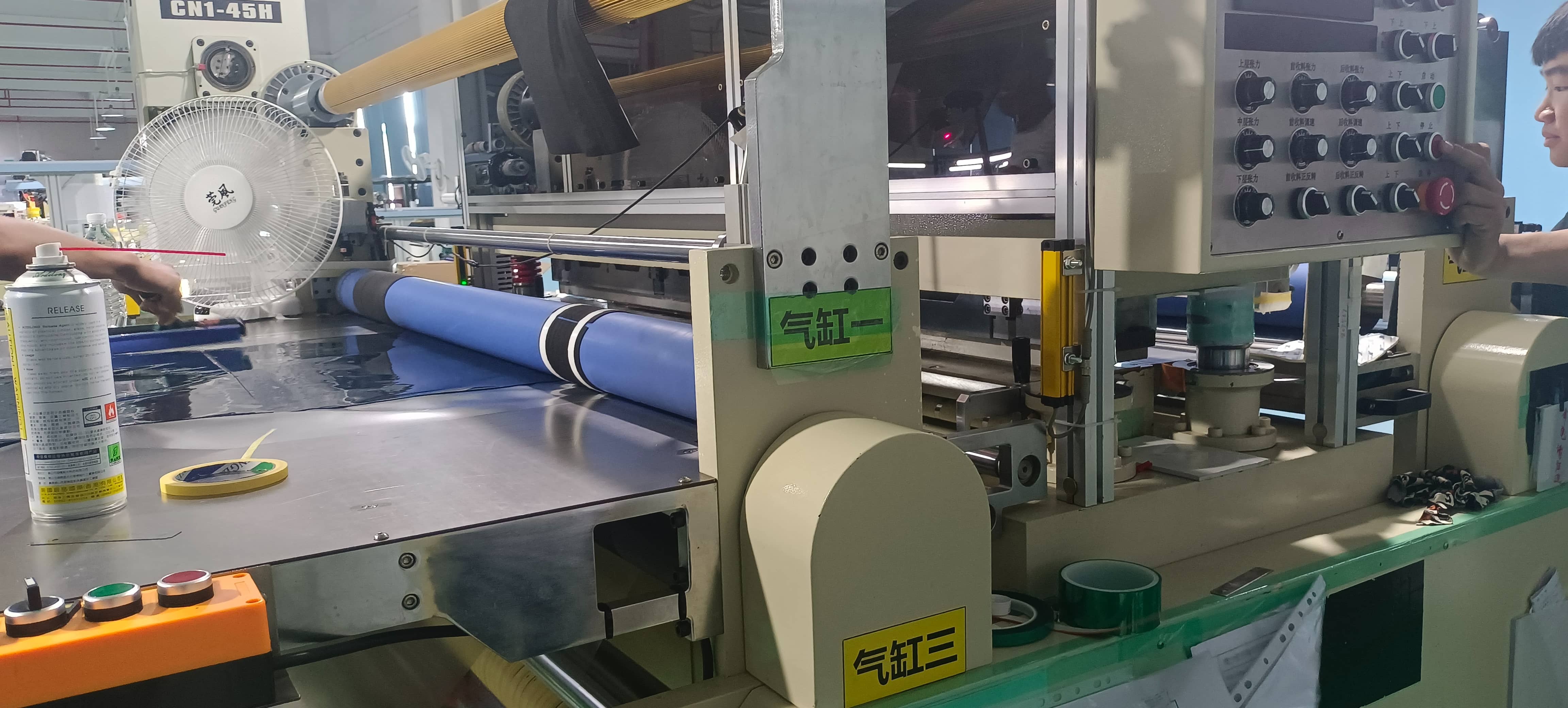

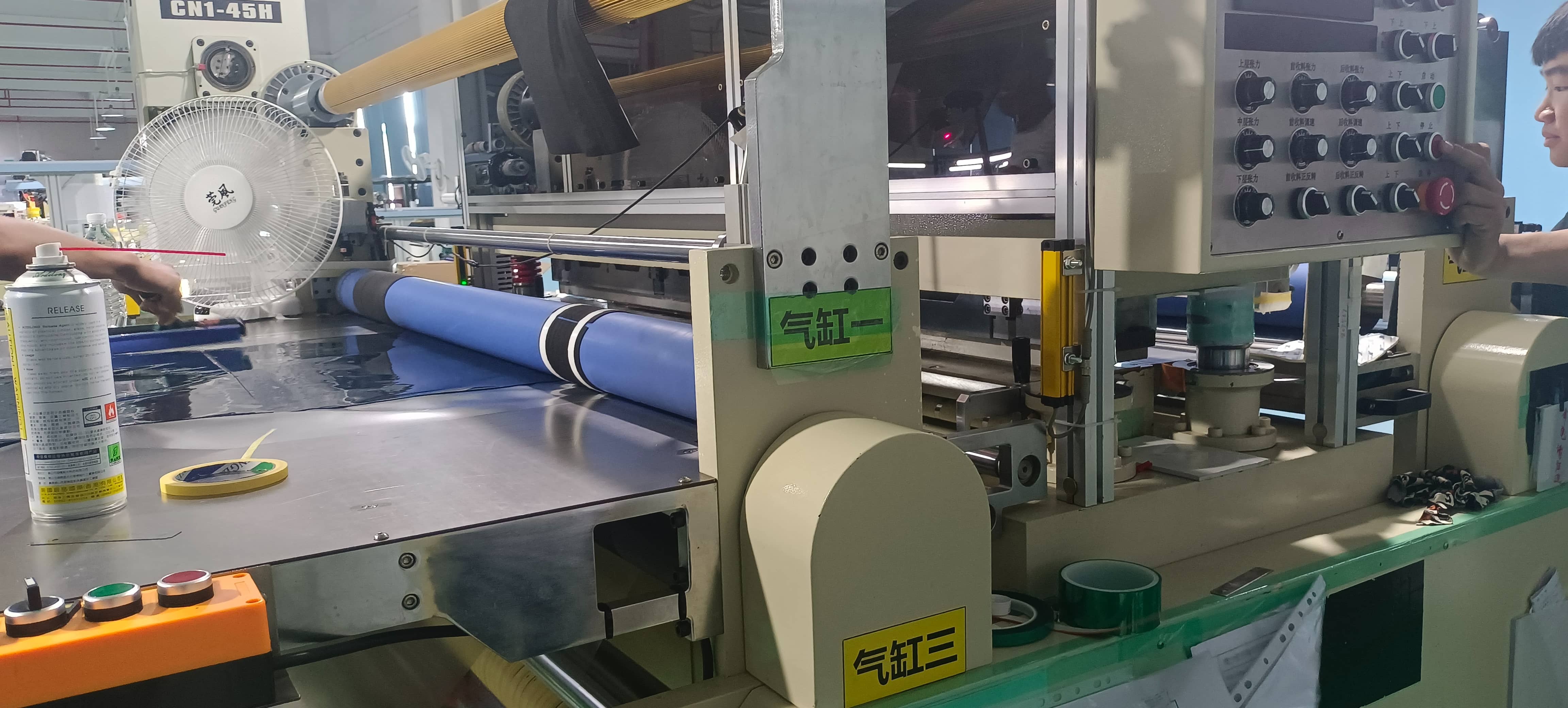

In the optoelectronic materials industry, safety light curtains are important equipment for asynchronous die-cutting protection. Safety light curtains protect operators by detecting objects or people entering their light beams to prevent accidents during the die-cutting process. The following is a safety light curtain solution for asynchronous die-cutting protection in the optoelectronic materials industry:

Choose the Right Safety Light Curtain

Resolution

Select the appropriate resolution to ensure that the minimum object size entering the danger zone can be detected. Usually for finger or palm protection, the beam spacing should be less than 20mm.

Protection height

Select the protection height of the light curtain according to the working height of the die-cutting equipment to ensure that the entire danger zone can be covered within the protection range of the light curtain.

Response time

Select a safety light curtain with a short response time to ensure that the equipment can be stopped in time when an object is detected.

The Role of the Safety Light Curtain

The safety light curtain forms an invisible beam barrier around the die-cutting equipment. When a person or object enters the beam, the light curtain will immediately send a signal to stop the operation of the equipment to avoid harm to the personnel. Its main functions include:

Preventing misoperation

Preventing operators from accidentally entering the dangerous area during the die-cutting process.

Improving production safety

Once a foreign object or person enters the range of the light curtain, the machine will stop immediately to prevent accidents.

Automated control

Integrated with the control system of the asynchronous machine to ensure that the die-cutting equipment operates in a safe state.

Installation of Safety Light Curtains

Installation location

Install the safety light curtain at the feed and discharge ports of the die-cutting equipment to ensure that the operator does not directly contact the tool area at any time.

Installation angle

According to the layout of the equipment, adjust the installation angle of the light curtain so that the light beam is perpendicular to the direction in which people may enter to ensure no blind spot protection.

Safety distance

According to the stop time of the equipment, calculate and set the safety distance between the safety light curtain and the dangerous area to ensure that after the light curtain is triggered, the equipment can stop before the person reaches the dangerous area.

Recommended Safety Light Curtain

DADISICK's Hot Selling Products

Beam spacing:40mm

Number of optical axes:20

Protection height:760mm

Safety sensors for machines output (OSSD):2 PNP

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.

Used for monitoring places such as safety doors and windows.