Application of Safety Light Curtains in Automated Metal Stamping Presses

- Share

- publisher

- Zoe

- Issue Time

- Jul 26,2024

Summary

In the process of automated metal stamping, ensuring the safe operation of robotic arms requires combining traditional safety measures with additional safety light curtains. Robotic technology offers flexible and tireless operation in many tasks that are dangerous for humans. Safety light curtains play a crucial role in defining and protecting the boundaries or perimeters between robotic work units and other areas of the factory.

Safety Light Curtains in Automated Metal Stamping Presses: Their Utilization and Importance

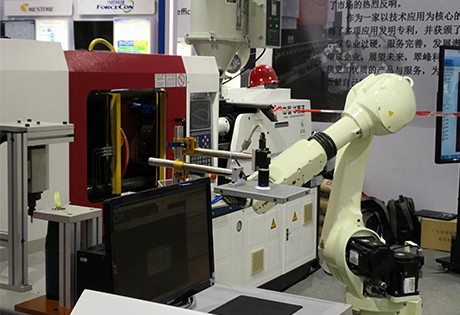

In the field of automated metal stamping, to ensure that robotic arms can operate safely and efficiently, we need to adopt traditional safety measures and additionally install safety light curtains as critical safety barriers. Robotic technology, with its flexibility and tireless nature, plays a key role in many dangerous tasks that humans are unwilling or unable to perform. However, this technological advancement also brings with it the responsibility to create safe working conditions for both humans and robots.

Stamping robots, as outstanding representatives of automated equipment, are specifically designed for automated stamping production lines, aiming to achieve unmanned production. They can fully replace manual work in stamping stations, including stamping, handling, and loading/unloading materials, significantly improving production efficiency and reducing labor costs. For industries with high repetition, high danger, and fast pace, such as stamping, stamping robots are not only a hallmark of modernization and industrialization but also show significant advantages in saving labor costs, enhancing labor and equipment safety, and maintaining product productivity, quality, and process stability.

However, it is worth noting that although stamping robots are powerful, they cannot completely replace manual operations. In certain situations, such as when the press gets jammed, manual intervention is still required for clearing. At this time, the role of safety light curtains becomes crucial. Safety light curtains effectively define and protect the boundaries between the robotic work unit and the rest of the factory, preventing personnel from accidentally entering dangerous areas. When someone enters the light curtain's protected area, the system immediately triggers a shutdown mechanism, ensuring the press stops operating to prevent accidents and ensure the safety of workers.

Recommended Safety Light Curtains

The QT series safety light curtains have achieved CE certification and offer excellent resistance to electromagnetic and optical interference. This series features superior shock resistance, waterproof and dustproof capabilities, and is equipped with comprehensive self-check and mutual check functions to ensure system reliability and safety.

Beam Spacing: Options available in 10 mm, 20 mm, 30 mm, 40 mm, 80 mm, and 200 mm to meet various safety requirements.

Sensing Range: Standard sensing range from 0.3 m to 6 m, with an extended range reaching up to 45 m, and heights up to 6 m.

Protection Categories: Provides finger protection, hand protection, and body protection to suit different application scenarios.

The QT series safety light curtains from DADISICK offer highly reliable safety protection in various industrial environments, especially suited for complex automated production lines and robotic operation areas.

Related Safety Protection Products

Beam spacing:10mm

Number of optical axes:70

Protection height:690mm

light curtain sensor output (OSSD):2 PNP

Used for monitoring places such as safety doors and windows.

Beam spacing: 80mm

Number of optical axes: 10

Protection height: 720mm

Safety Curtain outputs (OSSD):2 PNP