Application of Safety Mats in Industrial Robots: An Effective Safety Protection Solution

- Share

- Issue Time

- Aug 15,2024

Summary

This article explores the application of safety mats in industrial robots. Safety mats are crucial for detecting pressure changes and triggering safety mechanisms when personnel enter hazardous areas. They effectively enhance workplace safety by halting robot operations promptly. Ideal for automation, manufacturing, and automotive industries, the safety mats help prevent accidents and ensure smooth production processes.

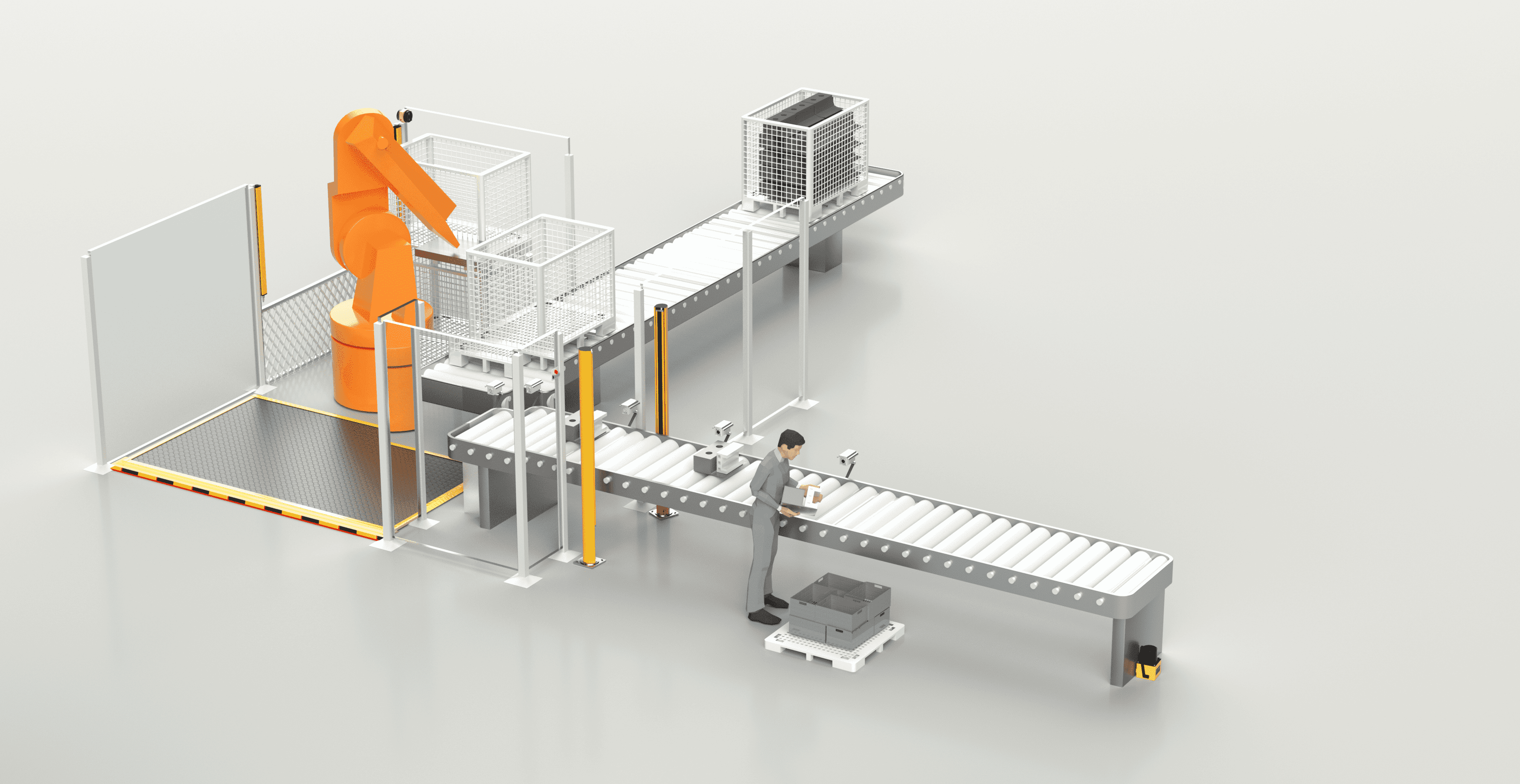

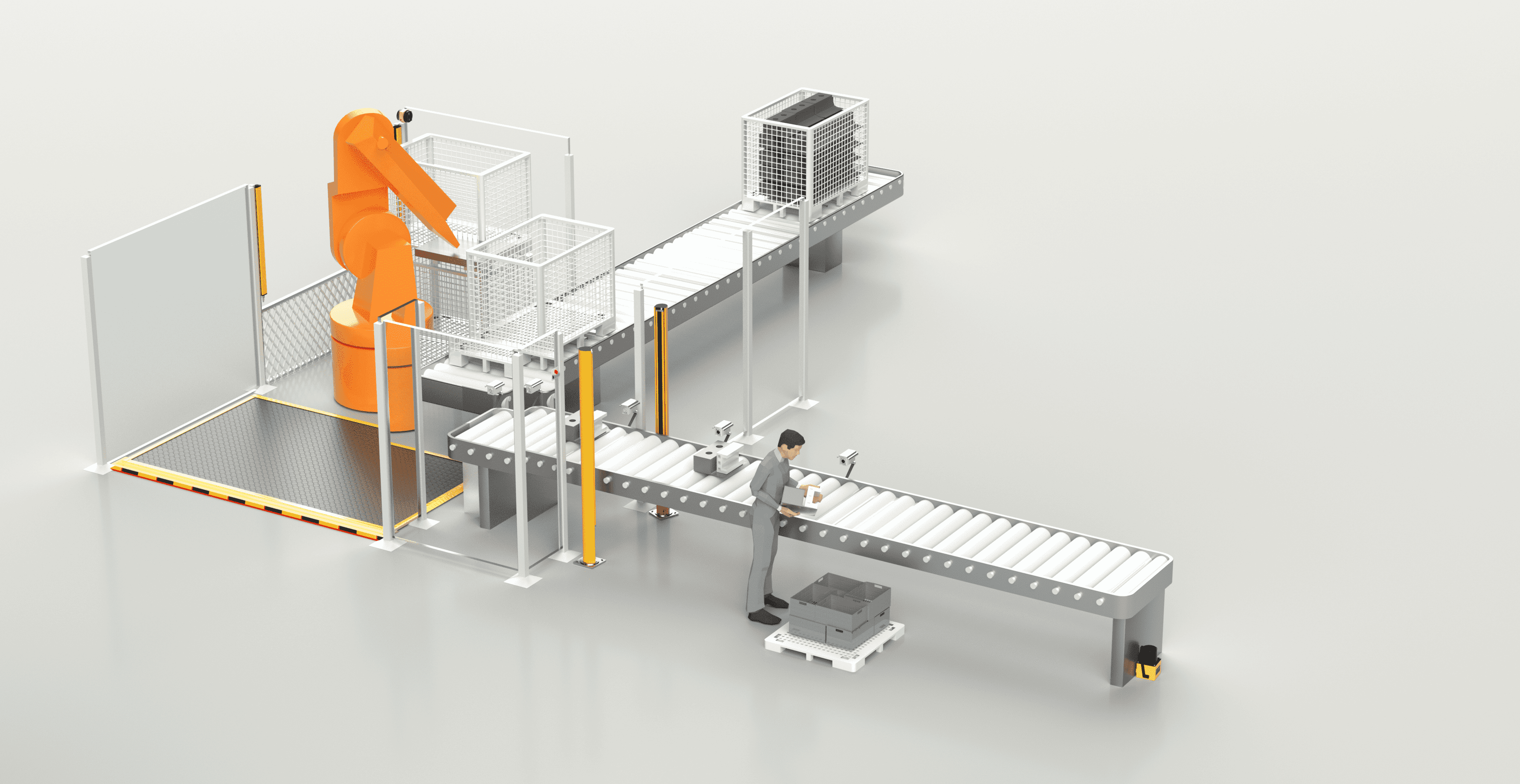

In modern industrial environments, with the widespread use of industrial robots, the need for safety protection in the workplace has become increasingly important. While industrial robots efficiently perform automated tasks, their high-speed operations and complex maneuvers present potential safety risks to nearby personnel. To ensure a safe working environment, safety mats have emerged as an effective protection device, widely used in guarding industrial robot work zones.

A safety mat is equipped with sensitive pressure sensors that detect when someone or something enters the danger zone. When triggered, the mat sends a signal to stop the robot, preventing accidents. One of the greatest advantages of this solution is its immediate response, preventing incidents without disrupting the normal workflow of industrial robots.

1. Real-Time Monitoring and Rapid Response

Safety pressure-sensitive mats feature highly sensitive pressure sensors that can instantly detect weight changes (such as a worker stepping into the robot's work area) and trigger the machine's stop function. This instant response effectively prevents potential accidents.

2. Flexible Configuration and Easy Installation

Safety mats are relatively easy to install and can be flexibly configured to cover different areas of the robot's workspace. Their modular design allows for easy expansion and maintenance, making them highly adaptable. Safety mats can be customized in different sizes and shapes to meet specific user requirements. They can be easily installed in various locations and connected in series or parallel to form larger protective areas as needed

3. Enhanced Safety with Reduced Downtime

Compared to traditional fencing or light curtains, safety pressure mat sensor ensure safety without significantly impacting production efficiency. When pressure is detected, the system automatically halts operation and can quickly resume production once the hazard is resolved, reducing downtime due to safety concerns.

4. Wide Range of Applications

Safety mats are suitable for various industrial environments. They are commonly used in automated production lines, such as automotive manufacturing, electronics production, and welding robot workstations. They are also used in hazardous areas like chemical processing and pharmaceutical manufacturing, where they help prevent accidents by detecting the presence of personnel or objects.

5. Strong Chemical Resistance

The protective layer of the safety mat has excellent chemical barrier properties. It is resistant to various chemicals such as diluted acids, diluted alkalis, non-oxidizing acids, metalworking oils, vegetable oils, alcohols, and soapy water. This makes them suitable for use in harsh chemical environments.

6. User-Friendly and Efficient

Compared to other protective methods like mechanical barriers, sliding doors, and pull-back limiters, safety mats are more flexible and labor-saving. They allow for full visibility and access to the work area while enhancing safety. They also simplify routine tasks such as machine setup, maintenance, and repair

At an automotive parts manufacturing plant, industrial robots are used for painting tasks. Due to the high-speed motion involved in painting, traditional fence protection could not offer enough flexibility. The plant introduced a safety pressure mat sensor system, covering the robot's work area floor. If an operator accidentally enters the danger zone, the safety mats detects this and immediately stops the robot's operation, preventing potential accidents. After installation, the system significantly reduced the downtime caused by safety issues, improving overall production efficiency.

In conclusion, the application of safety switch mats in industrial robots significantly enhances workplace safety by providing additional protection for operators and reducing the likelihood of accidents. This solution not only increases safety but also ensures continuous and efficient production.

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.