Global Measuring Light Curtain Manufacturers: A Buyer’s Guide

- Share

- publisher

- Zoe

- Issue Time

- Jun 18,2025

Summary

Discover the leading global Measuring Light Curtain manufacturers and their high-performance products. This buyer’s guide covers key features (high-resolution detection, fast response, robust design), compares top brands (Banner, Leuze, ReeR, etc.), Learn how to choose the right industrial measuring light curtain for your needs.

What Is a Measuring Light Curtain?

A measuring light curtain is a non-contact optical sensor system designed to detect, position, or measure objects as they pass through a defined detection zone. It consists of a transmitter and a receiver that together form a dense curtain of infrared light beams. When an object enters the detection area and interrupts certain beams, the system analyzes the blocked and unblocked beams to determine the object's size, position, or presence.

Operating Principle of Measuring Light Curtains

When powered on, the transmitter emits multiple parallel infrared beams directly toward the receiver, forming a "light curtain." As an object enters this field and blocks some of the beams, the receiver detects which specific beams are interrupted.

Measuring light curtains operate based on a synchronous scanning mechanism. During a scan cycle, the system activates one emitter channel at a time while the corresponding receiver channel listens for the specific signal. Once the transmission and detection for one beam pair are complete, the system moves to the next pair. A full scan cycle records the status of all beams—whether each is blocked or unblocked—and generates an output signal accordingly. This output can be analog or digital (e.g., RS485), depending on the model and application.

Scanning Modes of Measuring Light Curtains

There are two primary scanning modes for measuring light curtains: linear scanning and cross scanning.

● Linear Scanning Mode

In this configuration, the microcontroller sequentially sends matching selection signals to both the transmitter and receiver. For instance, channel 1 transmits and channel 1 receives, channel 2 transmits and channel 2 receives, and so on. This mode is widely adopted due to its simplicity and efficiency, especially in standard measurement applications.

● Cross Scanning Mode

In cross scanning, the microcontroller sends mismatched selection signals to the transmitter and receiver. For example, channel 1 transmits while channel 2 receives, then channel 2 transmits while channel 1 receives, and so on. This pattern continues through all beam pairs (e.g., channel 15 transmits → channel 16 receives, channel 16 transmits → channel 15 receives).

Cross scanning offers higher spatial resolution, especially for measuring object height. It is most accurate in the central third of the detection zone. Compared to linear scanning, the minimum measurable height can be reduced by approximately one-third. A representative product of this scanning method is the Panasonic Industry NA1-11 small/slim object detection sensor (now discontinued).

However, due to the higher complexity and cost of cross scanning systems, linear scanning remains the dominant choice for most practical applications.

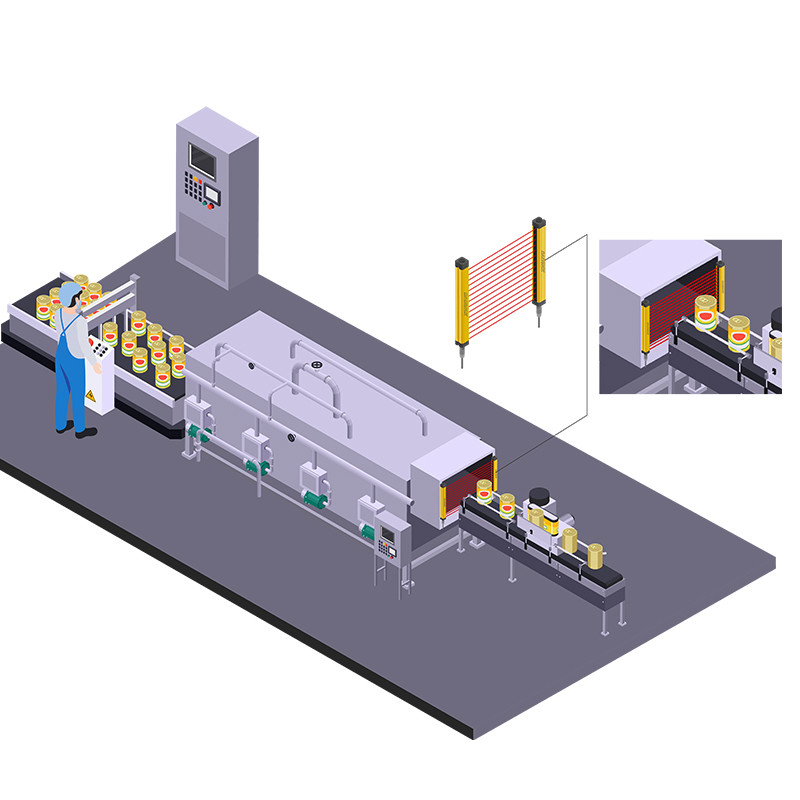

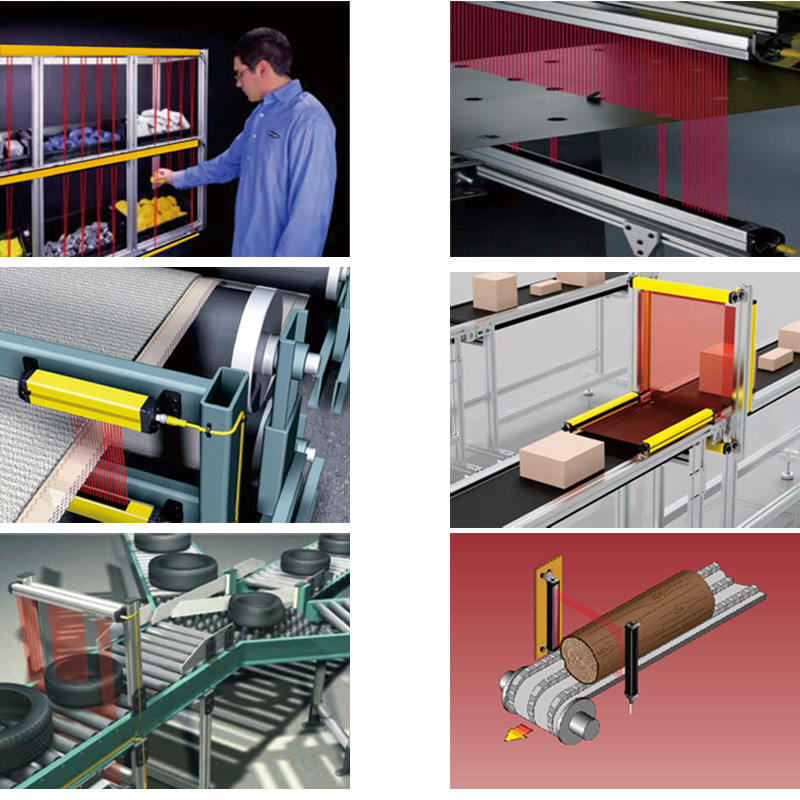

Applications of Measuring Light Curtains

Measuring light curtains offer a highly accurate, reliable, and non-contact method for object detection and measurement. They are widely used across various industries including manufacturing, logistics, packaging, and consumer electronics.

Common applications include:

● Dimensional measurement (height, width, profile)

● Object counting and sorting

● Centering and edge detection

● Hole and gap detection

● Tension control in web processing

● Position feedback in automated systems

● Quality inspection and precision alignment

Difference: Measuring Light Curtains vs. Safety Light Curtains | ||

While measuring light curtains and safety light curtains may appear similar in design, they serve distinct purposes: | ||

Feature | Safety Light Curtain | Measuring Light Curtain |

| Primary Function | Personnel safety protection | Object detection and dimension measurement |

| Output Type | Safety relay output (ON/OFF) | Analog output / serial data (e.g., RS485) |

| Reaction Behavior | Stops machinery when beams are blocked | Calculates object size or position based on blocked beams |

| Application Scenarios | Machine guarding, press protection, access control | Inspection, quality control, material handling |

In short, safety light curtains are designed for human protection, while measuring light curtains are optimized for process automation and object evaluation. | ||

Why Focus on Measuring Light Curtain Manufacturers?

When sourcing measuring light curtains, choosing the right manufacturer is more than a procurement decision—it's a strategic move that affects product quality, cost control, long-term growth, and brand strength.

1. Ensure Product Quality and Consistency

Understanding a manufacturer’s production processes, quality control systems, and raw material sources helps you evaluate the intrinsic quality of their products. Partnering with a reliable manufacturer ensures consistency across batches, reducing customer complaints and returns. Verifying their certifications—such as ISO quality management systems—also strengthens buyer confidence and reinforces your brand’s credibility.

2. Optimize Costs and Maximize Profitability

Working directly with manufacturers eliminates intermediaries, helping to reduce procurement costs. Bulk purchasing and long-term collaboration often lead to more favorable pricing. Additionally, having insight into the manufacturer’s production costs allows you to better control your pricing strategy and increase profit margins.

3. Build Long-term, Stable Partnerships

Establishing solid relationships with manufacturers opens the door to benefits such as priority supply, customized product development, and faster response times. Long-term collaboration fosters mutual trust, making it easier to navigate market fluctuations together. Staying in close contact with manufacturers also provides access to new product releases and industry trends—keeping your business competitive.

4. Strengthen Your Brand and Market Position

Collaborating with manufacturers that have a strong reputation and brand image can enhance your own product's perceived value. Co-developing innovative solutions boosts your brand's ability to differentiate in the market. Joint marketing efforts with a reputable manufacturer can also increase product exposure and raise brand awareness.

5. Adapt to Market Changes and Mitigate Risks

Understanding your manufacturer’s production capabilities and supply chain structure helps you adapt quickly to market shifts or unexpected events. Diversifying your suppliers by working with multiple manufacturers spreads risk and ensures business continuity. Additionally, aligning with manufacturers focused on technological innovation and product upgrades allows you to adjust your offerings promptly and maintain a competitive edge.

Key Selection Criteria for Measuring Light Curtains

1. Resolution & Beam Pitch

Smaller beam pitch delivers finer resolution. Match the beam spacing (e.g., 1.25 mm–5 mm) to the smallest feature you need to detect without incurring unnecessary cost.

2. Measuring Height Range

Defined as the vertical span from the first to the last light beam—ranges typically span from 60 mm to 3,000 mm. Select a height that comfortably exceeds your largest target dimension.

3. Environmental Robustness

Look for high IP ratings (IP65–IP68) and certifications for temperature and vibration resistance. Dust, moisture, and industrial noise can otherwise degrade performance.

4. Integration & Output Interfaces

Flexible output options—analog, RS‑485, IO‑Link, Ethernet—simplify connection to PLCs, PCs, or SCADA systems. Rich diagnostics over smart interfaces accelerate commissioning.

5. Installation & Maintenance Ease

Features like built‑in alignment indicators, LED beam‑status displays, and self‑diagnosis routines reduce setup time and ongoing service effort.

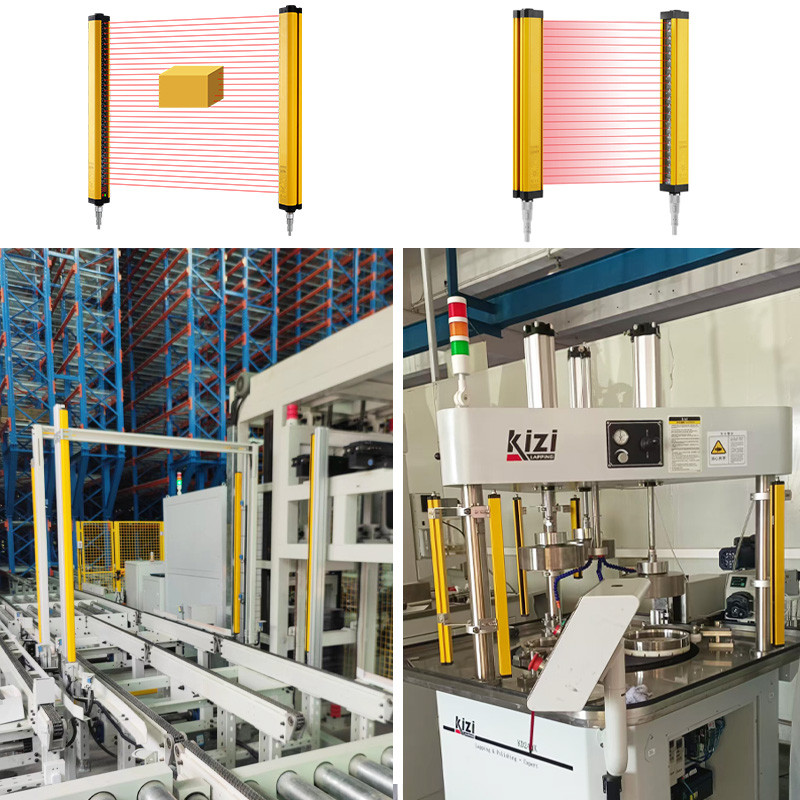

Top Global Measuring Light Curtain Manufacturers

| Manufacturer | Headquarters | Hot Series | ||

| Banner Engineering | USA | EZ-Array series measuring light curtain | ||

| Leuze | Germany | Universal light curtain, For Ex applications, For fast and transparent applications | ||

| ReeR | Italy | Micron series, Support Analogue output / Serial Output / ON/OFF output | ||

wenglor | Germany | Light curtains for measuring tasks | ||

Panasonic | Japan | NA1-11 (Discontinued) | ||

IFM | Germany | Measuring light grids | ||

DADISICK | China | QL series measuring light curtain | ||

Performance Comparison: DADISICK vs. Leading Brands

| Specification | Banner EZ-Array series | Leuze Universal measuring light curtain | ReeR Micron series | DADISICK QL series |

| Beam spacing (mm) | 2.5 / 5 / 9.5 / 19 mm | 5 / 10 / 20 / 40 mm | 5 / 10 / 25 / 30 / 50 / 75 mm | 1.25 / 2.5 / 5 / 10 / 20 / 40 / 80 mm |

| Height Range (mm) | 150 to 2400 mm | 130 to 2960 mm | 75 to 2990 mm | 60 to 3120 mm |

Range (Emitter to Receiver) | 400 mm - 4 m | Max. 7 m | Max. 18 m | 0.3 - 10 m |

Ingress Protection | IP65 | IP65 (Optional IP 67) | IP65 - IP67 | Default lP65 (Customizable IP68) |

Interface | IO-Link, Modbus-RTU, and RS-485 | Integrated PROFIBUS, PROFINET, CANopen, RS485, or IO-Link interface | Optional interface unit: Profibus, IDeviceNet, ICANopen, IEthernet IP, IEtherCAT, IPROFINET, IUSB Universal Serial Bus, IModBus RTU, IModBus TCP/IP | RS485, RS232 |

| Output Modes | Analog Output: • Current (4-20 mA)

• Voltage (0-10 V) Discrete Output: • NPN

• PNP

• PNP / Push-Pull | Analog output • Freely configurable • Voltage, Current | Analog Output:

• Current (4-20 mA)

• Voltage (0-10 V) Antivalent solid state digital outputs

Serial line (IO-Link protocol)

Serial line (RS-485) | Analog Output:

• Current (4-20 mA)

• Voltage (0-10 V) Discrete (Digital) Output • NPN NC • PNP NC • NPN NO • PNP NO |

Operating temperature | -40 ... 70 °C | -30 ... 60 °C | -10 ... 55 °C | -10 ... 40 ℃ (but not frozen) |

Ultimate Model Selection Guide for Measuring Light Curtains

Model Example: QL08/40-280BRF21B

• 8 beams

• 8 beams

• 40 mm beam pitch

• 280 mm effective measuring height

• PNP Normally Closed (NC) switching output

• RS485 communication interface

• Passive (response-based) transmission mode

• Baud rate: 9600 bps (default)

• Full beam status upload

• Sensing range: 0.3–6 meters

Ideal for applications requiring moderate resolution over mid-range distances, with stable digital communication and precise status reporting.

| Product Series | QL Series | ||

| Number of Beams | 04, 06, 08, 10 ... 500 | ||

| Beam Spacing | 1.25 / 2.5 / 5 / 10 / 20 / 40 / 80 mm | ||

| Measuring Height | Formula: (Number of Beams – 1) × Beam Spacing | ||

Switching Output Type (Optional) | Code: A, B, C, D • A: NPN NC (Normally Closed NPN) • B: PNP NC (Normally Closed PNP) • C: NPN NO (Normally Open NPN) • D: PNP NO (Normally Open PNP) ⚠️ If not specified, the default setting is no switching output. | ||

Signal Output Type | Code: R, S, U, I • R: RS485 • S: RS232 • U: Analog Voltage (0–10 V) • I: Analog Current (4–20 mA) | ||

Baud Rate (Data Transmission Speed) | Code: E, F, M, N • E: 4800 bit/s • F: 9600 bit/s (Default) • M: 19200 bit/s • N: 38400 bit/s | ||

Transmission Mode | Code: 1, 2 • 1: Active Mode, Device automatically uploads data periodically • 2: Passive Mode, Data sent upon host request | ||

Upload Format | Code: 1, 2 • 1: Uploads the status of all light beams • 2: Uploads only the position and count of blocked beam ⚠️ In active mode, the default upload interval is 50 ms. | ||

Detection Range (Sensing Distance) | Code: A, B, C • A: 0.3–3 m • B: 0.3–6 m • C: 0.3–10 m | ||

NOTE

Important Notes on Sensing Distance

Important Notes on Sensing Distance

• 1.25 mm pitch: Max range = 1 m

• 2.5 mm / 5 mm pitch: Max range = 3 m

• 10 mm and above: Max range = up to 10 m

Additional Specifications

Additional Specifications

• Communication Protocol: Modbus-RTU (standard)

• Configurable Parameters: Baud rate, transmission mode, and upload format can be customized via DADISICK's programming tool.

• Default Protection Rating: IP65 (custom IP rating available upon request)

• Upload Interval: 50 ms for active mode (fixed)

Related Measuring Light Curtain

Beam spacing: 2.5mm

Number of optical axes: 32

Protection height: 77.5mm

Beam spacing: 5mm

Number of optical axes: 304

Protection height: 1515mm

Beam spacing: 10mm

Number of optical axes: 80

Protection height: 810mm

Beam spacing: 20mm

Number of optical axes: 136

Protection height: 2700mm