How Relay Modules Achieve Functional Safety Improvements?

- Share

- Issue Time

- Sep 9,2024

Summary

Safety relays offer larger size, modular design, high diagnostic coverage, fail-safe features, and forced contact structure. Normal relays lack these safety-critical attributes, making them unsuitable for high-risk applications.

Electromechanical relays are typically used to control high power circuits with low power signals. They act as switches, allowing or blocking the passage of current depending on the state of the input signal. Relay modules are used in functional safety applications to ensure that safety-critical functions are performed reliably and to minimize potential hazards. Some of the most important.

Aspects of Relay Modules in Functional Safety Applications are Listed Below

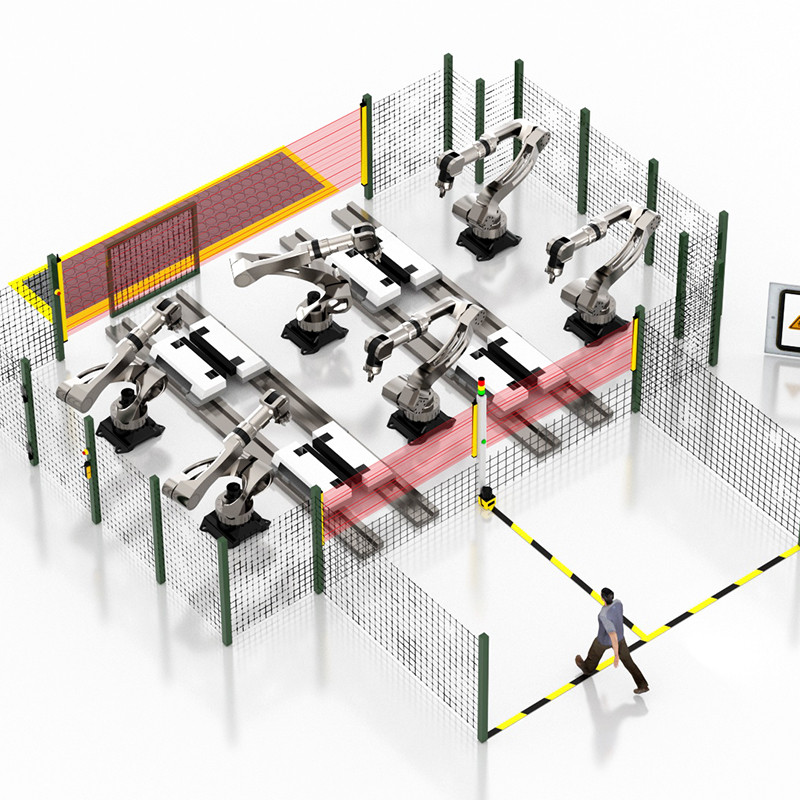

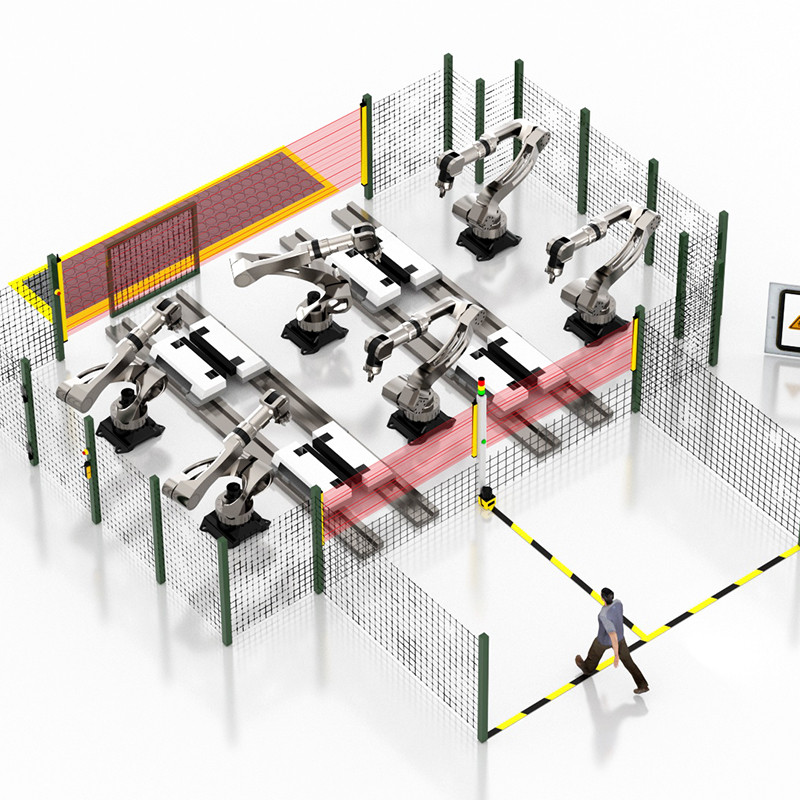

Redundancy: Redundancy is one of the basic principles of functional safety, requiring multiple independent components to perform the same safety-critical function. Relay modules are typically configured with redundancy to ensure that the system will continue to operate safely even if one relay fails.

Fail-safe design: Relay modules are typically designed to be fail-safe; if a relay fails or loses power, it defaults to a state that ensures system safety. For example, failure of a relay in a machine's E-stop control circuit will result in immediate shutdown.

Diagnostics and monitoring: These features are built into the advanced relay modules, allowing the system to detect defects or faults in the relays and initiate an appropriate response, such as a fault alarm or switching to a redundant relay.

Reliability and Ruggedness: Relay modules are known for their durability and reliability. They can withstand extreme environmental conditions, temperature fluctuations, and mechanical stress, making them suitable for use in demanding industrial environments.

Low delay: Response time is critical in safety-critical applications. Relay modules are preferred in applications that require fast response times to ensure the safety of personnel and equipment.

There are several factors to consider when using relay modules in functional safety applications, the first of which is compliance with standards. This ensures that relay modules used in functional safety applications comply with relevant safety standards and certifications.

Power supply: 24 V DC

Relay safety output: 3NO + 1NC (PNP or NPN)

Maximum switching capacity: 12 A (Distributed on all safety output contacts)

Transistor signal output: <500 mA 24 V DC

Contact resistance: <100 mΩ

Size: 117 × 100 × 22.5 mm

Shell material: flame retardant PA66

Storage temperature: -40℃ ~ 105℃

1.Larger appearance: the external dimensions of safety relays and ordinary relays are not the same, and safety relays are larger.

2.Module instead of component: safety relay is a module, not an electronic component like ordinary relay.

3.Safer core: Due to the difference in design principle: ordinary relays can not achieve high diagnostic coverage (DC) and can only be applied to lower safety level machinery industry such as Cat.B/1, process control industry SIL1, it can be considered that ordinary relays are not safe enough. While the safety relay by the requirements and logic circuits of the auxiliary design, its diagnostic coverage is higher, and even some can reach 99.9%. Moreover, in some cases with high safety requirements, there are regulations that require the use of certified safety relays to meet the safety requirements!

4.Forced structure: "Safety relays are not "fault-free relays", but they make regular movements in the event of a malfunction. Safety relays have a forcibly guided contact structure (or other protection methods) to ensure safety in case of contact welding, which is completely different from general relays.

Ordinary relay: When the contacts are melted, both contacts (NO/NC) turn ON at the same time.

Forcibly guided relay: The core element of the safety relay is the forcibly guided relay, under the action of the internal forcibly guided lever, even if the contacts are melted, it will not make both contacts (NO/NC) turn ON at the same time.