How to Choose the Perfect Industrial Safety Mat | Dadisick

- Share

- Issue Time

- Jul 5,2025

Summary

Discover how to select the ideal industrial safety mat for your facility. Learn about types, key factors, installation, and compliance with Dadisick's guide.

In industrial settings, ensuring worker safety is a top priority. Industrial Safety Mats are critical pressure-sensitive devices designed to detect personnel presence, halting machinery to prevent accidents in hazardous areas. Selecting the right safety mat can enhance workplace safety, boost compliance, and protect your team. At Dadisick, a trusted leader in safety solutions since 2006, we provide high-quality safety mats tailored to diverse industrial needs. This guide will help you choose the perfect Industrial Safety Mat for your facility, blending expertise with practical advice.

Types of Industrial Safety Mats

Industrial pressure mat sensor are pressure-sensitive devices designed to detect the presence of workers or objects on their surface area. When a person steps on the safety mat, it triggers a stop signal, preventing potential injuries caused by hazardous equipment. These safety mats offer a wide horizontal detection area, making them ideal for protecting dangerous areas in industrial and production automation settings. Choosing the right type of safety mat starts with understanding your options. Here' s a breakdown of common types and how Dadisick meets these needs:

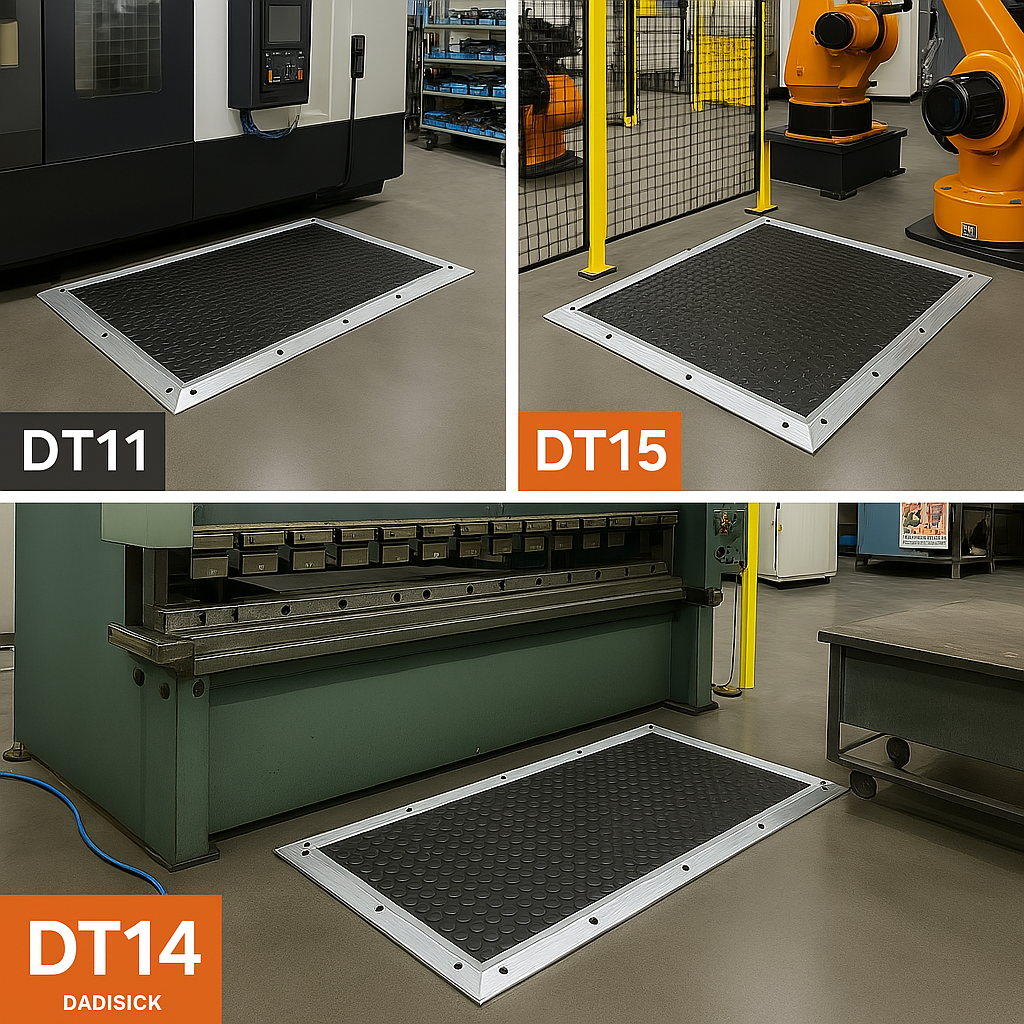

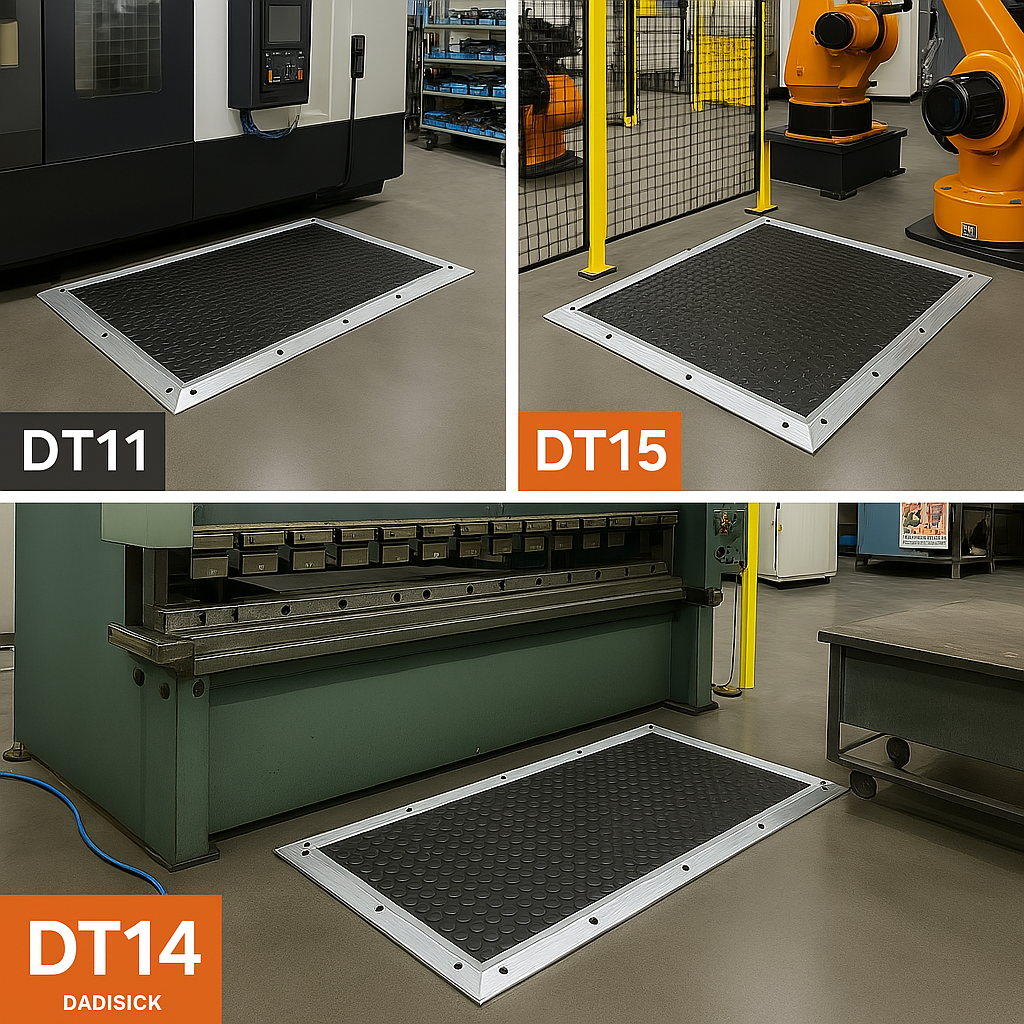

Standard Safety Mats

Perfect for general use, these safety mats detect foot traffic and stop machinery. Dadisick' s DT11 Series is an excellent choice for typical industrial environments.

Heavy-Duty Safety Mat

Built for high-traffic or heavy-equipment zones, these offer superior durability. Our DT15 Series excels in harsh conditions like extreme temperatures or chemical exposure.

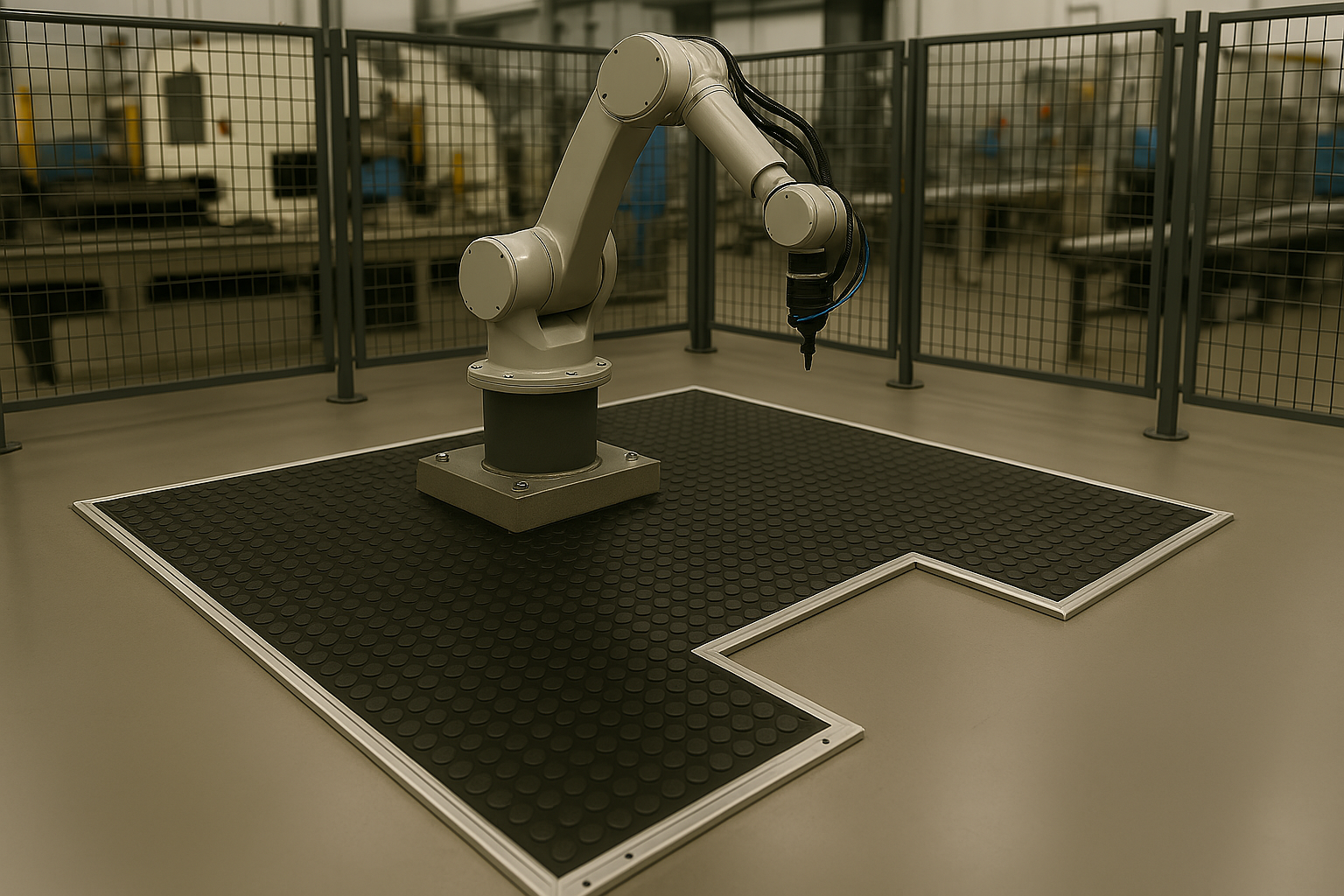

Custom-Shaped Industrial Safety Mats

For irregular or unique areas, custom mats ensure full coverage. Dadisick offers tailored solutions to fit any layout.

Non-Isolated Industrial Pressure Mat Sensor

Cost-effective for specific applications, these mats suit less complex setups. The DT14 Series from Dadisick is ideal for such scenarios.

With a range of options, Dadisick ensures you find the perfect fit for your safety requirements.

Key Factors to Consider When Choosing an Industrial Safety Mat

To select the ideal Industrial Safety Mat, evaluate these essential factors:

Pressure Sensitive Safety Mats Application Environment

Tapered edge safety pressure mat are ideal for placement in areas with rolling equipment, while straight edge mats are perfect for multi-mat configurations. Diamond plate safety mats are rugged and designed to handle heavy industry applications.

We also need to identify the specific areas where the industrial safety pressure mats will be used. Is it for protecting workers around machinery, or for securing access points to hazardous zones? Different applications may require varying sizes, shapes, and sensitivities of safety mats.

General Use: For standard conditions, Dadisick' s DT11 Series (PVC-encapsulated) provides reliable protection.

Harsh Conditions: In oil-prone or corrosive environments, opt for the DT15 Series (NBR rubber-encapsulated) for enhanced durability.

Size and Coverage Area

Based on the coverage needed, select the right size and configuration of the safety mat. Measure your hazardous zone precisely. Pressure safety mats should cover the entire area without gaps. Dadisick pressure sensitive safety mat like the DT11 and DT15 can connect up to 6 units (max 6 sqm), while the DT14 supports 5-6 units (max 3-4 sqm).

Pressure Safety Mat Sensitivity and Trigger Weight

Safety Pressure Mats Material and Durability

Consider the environmental conditions of your workplace. If the area is exposed to oil, dust, moisture, or extreme temperatures, choose safety mats with appropriate resistance and durability. DADISICK's safety mats feature excellent anti-slip properties and are resistant to various contaminants, making them suitable for harsh environments up to IP65 rating.

PVC Safety Pressure Mats: Great for general wear (DT11).

NBR Rubber Safety Mat: Resist oil and corrosion (DT15). Dadisick' s safety pressure mats feature anti-skid surfaces for added safety.

Installation and Maintenance

Look for easy-to-install options. Dadisick provides aluminum edges and connectors, plus detailed guides, ensuring hassle-free setup and upkeep.

Safety Standards Compliance

Machine safety pressure mats must meet standards like EN 1760-1 and ISO 13856-1. All Dadisick products are rigorously tested to exceed these benchmarks, ensuring top-tier safety.

Installation Tips for Machine Safety Pressure Mats

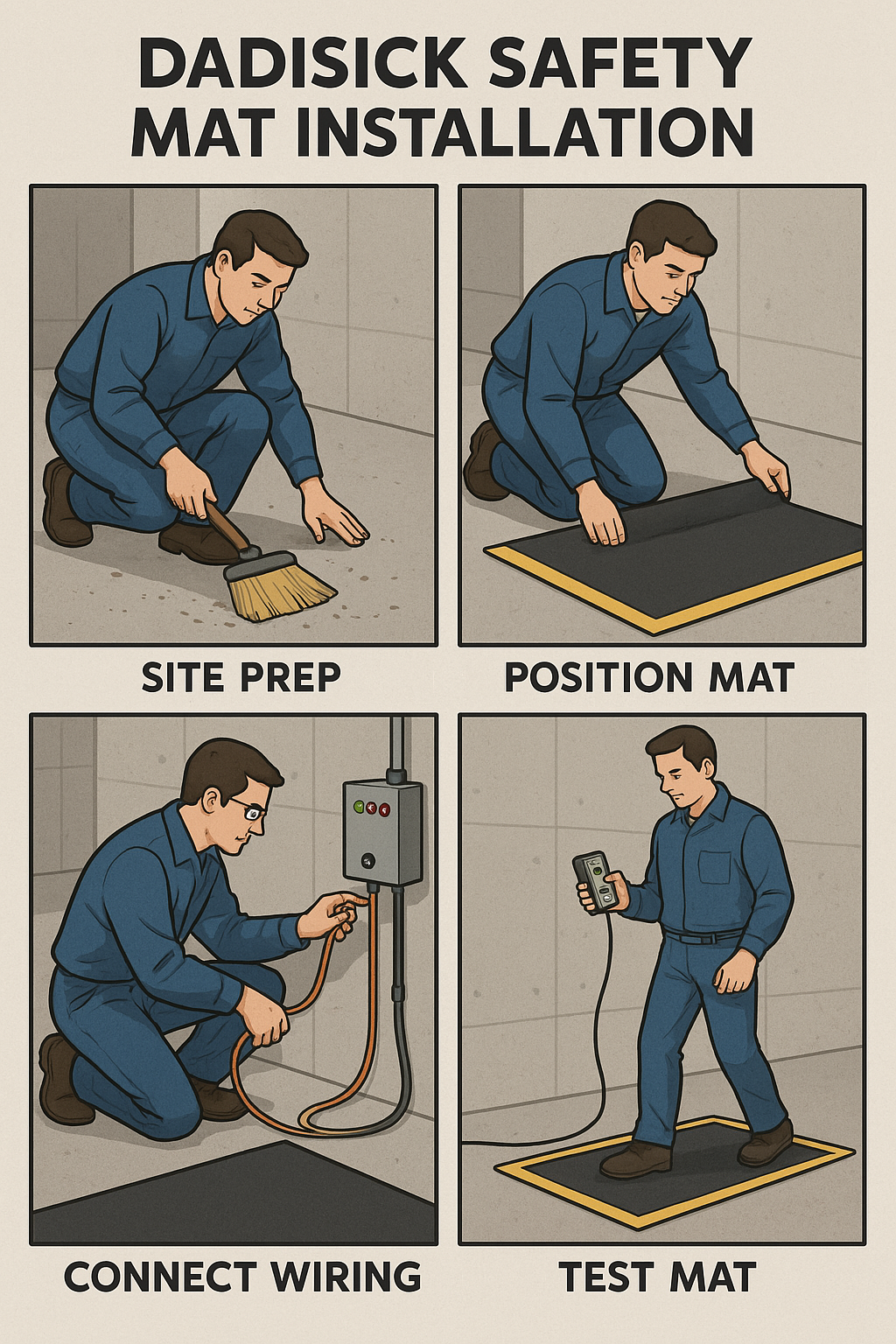

Proper installation maximizes safety mat performance. Follow these steps:

1. Prepare the Site

Ensure a flat, clean, debris-free surface. Uneven floors can impair functionality.

2. Position the Mat

Place the mat to cover the entire hazard zone. For larger areas, connect Dadisick mats in series (e.g., DT11/DT15 up to 6 units).

3. Secure the Mat

Use Dadisick’s aluminum edges or fixing accessories to anchor the mat, preventing shifts.

4. Connect to Safety Relays

Wire to a compatible relay like Dadisick' s Ter-A Series for seamless machinery control.

5. Test the System

Step on the mat to confirm it triggers the relay and stops equipment as intended.

For detailed instructions, download our [Installation Guide]

Ensuring Safety Compliance

Compliance with industry standards is non-negotiable. Dadisick' s Industrial Safety Mats meet:

EN 1760-1: Pressure-sensitive protective device standards.

ISO 13856-1: Safety equipment requirements.

Our rigorous testing and certification process ensures your workplace adheres to global safety norms, offering peace of mind.

Why Choose Dadisick for Industrial Safety Mats?

Since 2006, Dadisick (Dongguan Dadi Electronic Technology Co., Ltd.) has been a pioneer in industrial safety, serving over 2,000 clients across 20+ countries. Here’s why we stand out:

Expertise: Decades of experience in safety solutions, backed by a skilled R&D team.

Quality: Our mats are durable, reliable, and tested to exceed standards.

Customization: Tailored mats for any space, ensuring complete protection.

Support: From selection to installation, our team is with you every step.

Testimonial: *"Dadisick' s DT15 mats transformed our factory’s safety. Durable, easy to install, and fully compliant – we couldn’t ask for more."* – [John Doe, Manufacturing Manager]

Conclusion

Selecting the perfect Industrial Safety Mat is vital for a safe, compliant workplace. Consider your environment, size needs, and compliance requirements to make an informed choice. At Dadisick, we’re committed to delivering top-quality safety mats that protect your team and equipment.

Ready to enhance your safety? [Contact us] or explore our [product range] today!

Related Hot-sale Products

Detection Method: Pressure sensing method

Pressure Resistance: Dynamic load up to 500kg, static load up to 700kg

Trigger Force: 30 kg (for adults)

Surface Protection Material: NBR rubber

Mat Thickness: 14 mm

Detection Method: Pressure sensing method

Maximum allowable load (8 hours) ≤ 400 N/cm²

Trigger Force: >20 kg

Surface Protection Material: NBR rubber

Mat Thickness: 15 mm

Detection Method: Pressure sensing method

Maximum allowable load (8 hours) ≤ 200 N/cm²

Trigger Force: >20 kg

Surface Protection Material: PVC

Mat Thickness: 11 mm

Multifunctional safety relay, providing automatic/manual reset configuration and multifunctional configuration DIP switch, used for industrial field monitoring of various signals with high safety requirements.

Safety Edges is a technology that monitors the pressure distribution on the carpet through pressure sensing.