LD-05D Safety Laser Scanner: Pallet Shuttle Cart Obstacle Avoidance Solution

- Share

- publisher

- Zoe

- Issue Time

- Aug 21,2024

Summary

The pallet shuttle cart, used in warehouses and logistics parks, improves material transportation efficiency but poses safety risks. To mitigate these risks, installing the LD-05D safety laser scanner at the front of the cart is recommended. The scanner detects objects entering pre-defined warning zones and triggers an alarm, enabling the system to take evasive action.

LD-05D Safety Laser Scanner: Pallet Shuttle Cart Obstacle Avoidance Solution

The pallet shuttle cart, a type of electric logistics equipment, is widely used in large warehouses and logistics parks for material transportation. It improves transportation efficiency and reduces costs, but also presents certain safety risks during operation. To ensure the safety of personnel and the proper functioning of equipment, the following solution is recommended

Solution:

A safety laser scanner, specifically the LD-05D, should be installed at the front of the pallet shuttle cart. The scanner is configured with pre-defined warning zones by the user. When the LD-05D detects an object entering this zone, it immediately outputs an alarm signal. The system processing the signal then takes action to avoid obstacles, thus protecting both personnel and property.

2D TOF Safety Laser Scanning Factory On-Site Obstacle Avoidance Testing

Our customer installed the LD-05D safety laser scanner on their cargo transport equipment. According to the video feedback from the customer, the laser scanner is mounted on the front side of the equipment. When an object or person is detected within the preset range, it sends a signal to the system, causing the equipment to stop operating.

Working Principle of the LD-05D Safety Laser Scanner

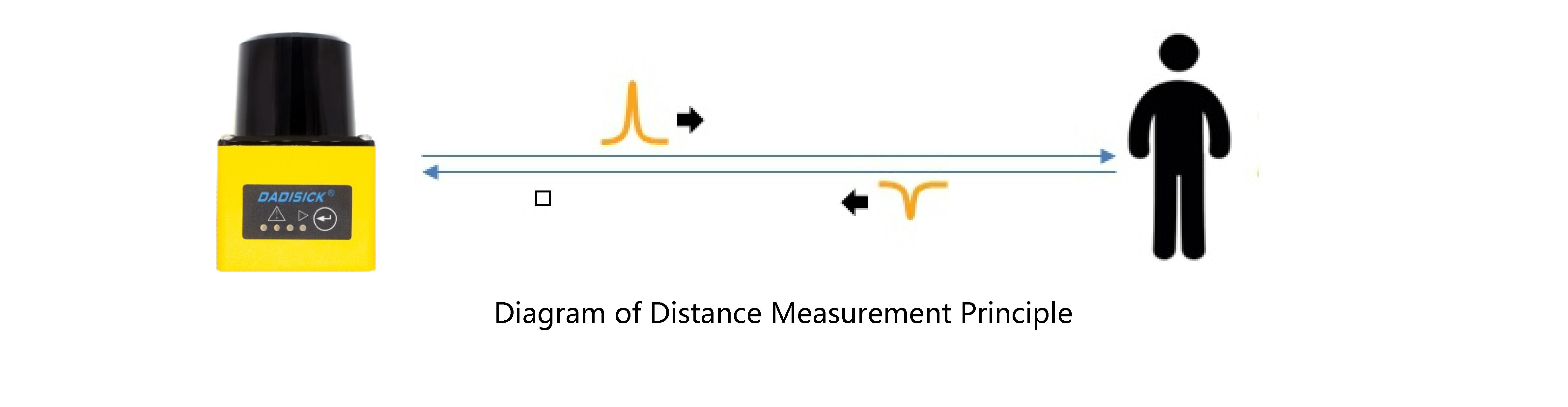

The LD-05D is a TOF (Time of Flight) laser scanner. Its core components include optics, mechanics, circuits, and software. During operation, the laser scanner emits a beam that reflects off objects. The receiver detects the reflected light signal, and the time analysis module measures the time difference between the emitted and reflected light. By multiplying this time by the speed of light, the distance to the object is calculated, allowing the position of the object to be determined, as illustrated in the diagram:

Diagram of the Laser Scanner Distance Measurement Principle

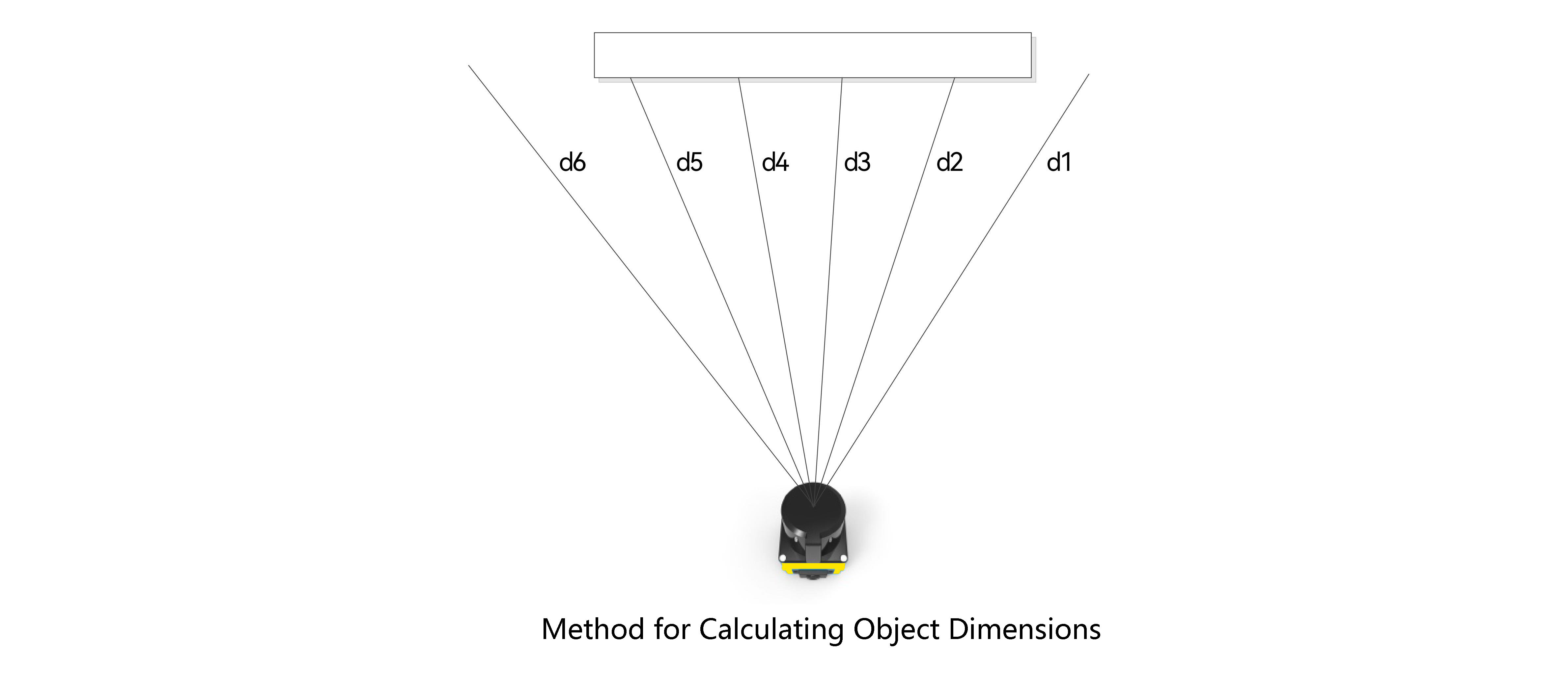

Method for Calculating Object Dimensions

Formula for Calculating Object Dimensions

Suppose the distances measured by the scanner are d1, d2, …, d6, representing the distances between the object and the laser scanner. The angular difference is the angular resolution of the LD-05D.

The formula for calculating the object's dimensions is:

W = (d2 + d3 + d4 + d5) * θ

Note:

θ = (2π/360) * angular resolution

The angular resolution is related to the scanner's rotation speed and can be set by the customer through the software.

Recommended Safety Laser Scanner

Laser Source: 905 nm (Class I)

Scanning Angle Range: 270°

Scanning Frequency: 15 Hz / 30 Hz

Angular Resolution: 0.1° / 0.3°

Operating Range: 0.05 m ~ 5 m

Detection Range at 10% Object Reflectivity: 2.5 m

Self-Learning Function: Automatic environmental scanning and region generation

Recognizable Object Shapes: Almost any shape

Number of Zone Groups: 16 zone groups, each containing 3 zones

Measurement Error: ±30 mm

Housing Color: Yellow

Enclosure Protection Rating: IP65

Weight: 150 g (excluding cable)

Operating Temperature: -10°C ~ 55°C

Dimensions (L x W x H): 50 mm x 50 mm x 76 mm