Pressure Sensitive Safety Mats: Installation and Maintenance Best Practices

- Share

- Issue Time

- Jul 9,2025

Summary

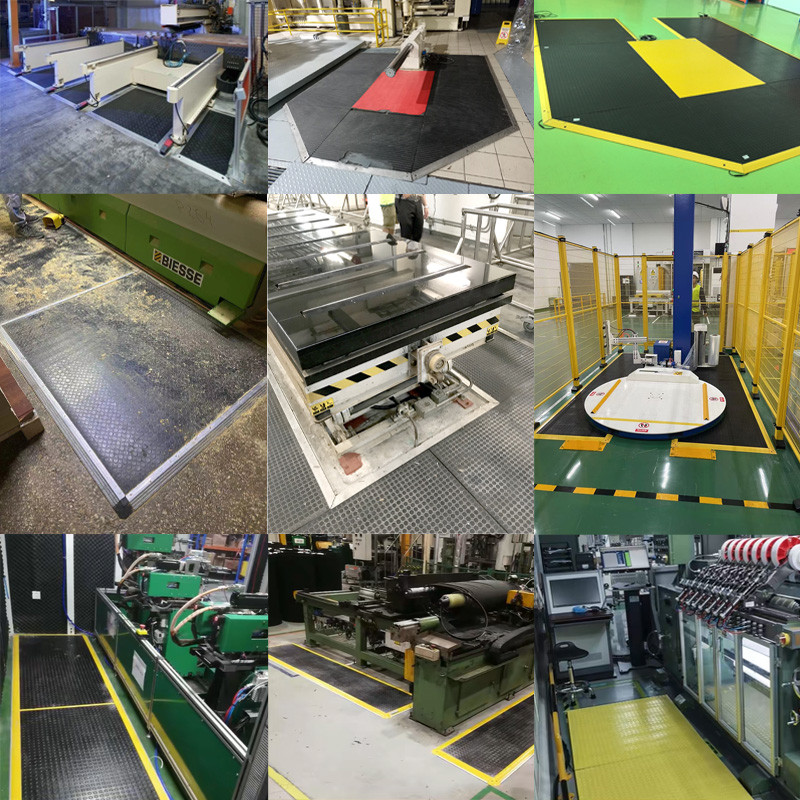

Ensure workplace safety with proper installation and maintenance of pressure-sensitive safety mats. Learn best practices and discover how Dadisick's industrial safety mats protect your workforce and meet compliance standards.

Introduction: Ensuring Safety in Industrial Environments with Safety Mat

Worker safety is a top priority in industrial settings, where the risk of accidents is ever-present. According to the Occupational Safety and Health Administration (OSHA), over 2.8 million nonfatal workplace injuries were reported in the U.S. in 2019 alone. Many of these incidents could be mitigated with advanced safety solutions like Industrial Safety Mats. These pressure-sensitive mats detect human presence in hazardous zones, instantly halting machinery to prevent injuries.

At Dadisick, we are committed to enhancing workplace safety through innovative, high-quality Industrial Safety Mats. With over a decade of expertise in safety technology, our products are engineered to protect your workforce while boosting operational efficiency.

Why Pressure-Sensitive Safety Mats Are Essential

Pressure-sensitive safety mats are critical components of industrial safety systems. When a worker steps onto the pressure sensor mat, it triggers an immediate stop signal to nearby machinery, preventing potential accidents. This technology is ideal for environments with automated equipment or heavy machinery, offering a proactive approach to safety.

Key Benefits of Dadisick's Industrial Safety Mats

● High Trigger Sensitivity: Detects individuals weighing as little as 20kg, ensuring comprehensive protection.

● Durability: Built to endure harsh conditions, with the DT15 series safety mat featuring NBR rubber encapsulation for oil and corrosion resistance.

● Customizability: Available in various sizes and shapes to suit any workspace, from small stations to expansive production floors.

● Compliance: Meets international standards like EN 1760-1 and ISO 13856-1, guaranteeing reliability.

Installation Best Practices for Industrial Safety Mats

Proper installation is key to maximizing the effectiveness of Industrial Safety Mats, here are the essential steps:

1. Preparation

Proper preparation is essential for successful installation. Follow these guidelines:

● Inspect the mounting surface to ensure it's flat, smooth, and free of debris

● Choose appropriate mounting tools and materials

● Familiarize yourself with the installation manual and product specifications

2. Assess the Installation Area

● Identify hazardous zones where machinery poses risks.

● Ensure the surface is flat and free of debris or holes larger than 20mm, as unevenness can compromise functionality (DT14 Datasheet).

4. Prepare the Site

● Clean the floor to remove dirt, oil, or particles that could affect adhesion or sensitivity.

● Ensure the surface is dry and level to prevent false triggers.

5. Mounting the Pressure Sensing Mat

● Position the mat precisely, using accessories like aluminum blank holders or expansion bolts.

● Maintain fluid-tight connections, especially in wet environments, protect wires from damage using conduits or wire raceways

● Ensure proper alignment of mats and trim

● Avoid dragging cables during placement, as this can damage signal wiring.

6. Electrical Connections: Connect to the Safety Relay

● Follow the wiring diagram provided with your safety mat control device, wire the industrial safety floor mat to a compatible safety relay (e.g., Dadisick's Ter-A series or LS-A series) following the datasheet instructions.

● Take DADISICK'S safety mats as example: For DT14 series industrial safety mats's four-wire system, connect black/white for normally open and red/yellow for detection.

Maintenance Best Practices for Long-Term Performance

Regular maintenance ensures your Industrial Safety Mats remain effective over time. Here's how to keep them in top condition:

1. Routine Inspections

● Check for wear, cuts, or damage to the protective layer. Replace any compromised pressure sensitive safety mats promptly.

● Verify the safety pressure mat is securely fixed with no gaps or overlaps.

● Verify that the control system responds correctly to industrial safety pressure mat activation.

2. Cleaning the Pressure Safety Mats

● Sweep or vacuum regularly to remove debris.

● Use a mild detergent and soft cloth to clean the surface. Avoid harsh chemicals that could degrade the pressure sensitive safety mat (e.g., DT11's PVC layer is less resistant to solvents than DT15's NBR).

● Increase cleaning frequency in high-traffic or dusty areas.

3. Safety Pressure Mats System Testing

● Periodically test the pressure safety mat’s trigger function to confirm it activates the safety relay and stops machinery.

● Ensure all wiring connections remain secure.

4. Environmental Monitoring

● Avoid exposing machine safety pressure mats to conditions beyond their specs (e.g., DT11: +10°C to +55°C; DT15: +10°C to +65°C).

● Check for compression or deformation under heavy loads (max 200 N/cm² for DT11, 400 N/cm² for DT15).

Why Choose Dadisick for Your Industrial Safety Mats?

Dadisick stands out as a leader in safety technology, blending innovation with reliability. Our Factory Introduction showcases a state-of-the-art facility in Dongguan, China, where advanced manufacturing and rigorous R&D ensure top-tier Industrial Safety Mats.

Dadisick's Unique Advantages

● Innovation-Driven: Our R&D team continuously enhances safety solutions to meet industry demands.

● Quality Assurance: Every industrial safety mat undergoes strict quality checks to deliver unmatched durability and performance.

● Expert Support: Our team provides guidance on installation, maintenance, and customization.

Conclusion: Elevate Safety with Dadisick's Industrial Safety Mats

Investing in Industrial Safety Mats is a proactive step toward a safer workplace. By adhering to installation and maintenance best practices, you ensure long-term protection and compliance. At Dadisick, we’re dedicated to delivering solutions that prioritize your workforce’s safety.

Explore our range of Industrial Safety Mats and see how our cutting-edge technology can transform your facility. For more details or a custom quote, contact us today.

Detection Method: Pressure sensing method

Pressure Resistance: Dynamic load up to 500kg, static load up to 700kg

Trigger Force: 30 kg (for adults)

Surface Protection Material: NBR rubber

Mat Thickness: 14 mm

Detection Method: Pressure sensing method

Maximum allowable load (8 hours) ≤ 400 N/cm²

Trigger Force: >20 kg

Surface Protection Material: NBR rubber

Mat Thickness: 15 mm

Detection Method: Pressure sensing method

Maximum allowable load (8 hours) ≤ 200 N/cm²

Trigger Force: >20 kg

Surface Protection Material: PVC

Mat Thickness: 11 mm

Multifunctional safety relay, providing automatic/manual reset configuration and multifunctional configuration DIP switch, used for industrial field monitoring of various signals with high safety requirements.

Economical safety relay, dual-channel safety monitoring circuit design, suitable for high-demand fields such as mechanical protection, automated production lines and robot systems.